Water-borne white board pen ink capable of being wiped dryly or with wiping agent and wiping agent thereof

A pen-ink and wet-wiping technology, which is applied in chemical paint/ink removers, inks, household appliances, etc., can solve the problems of poor storage stability, easy volatilization, inconvenient use, etc., and achieves simple preparation process, stable performance, and formula simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

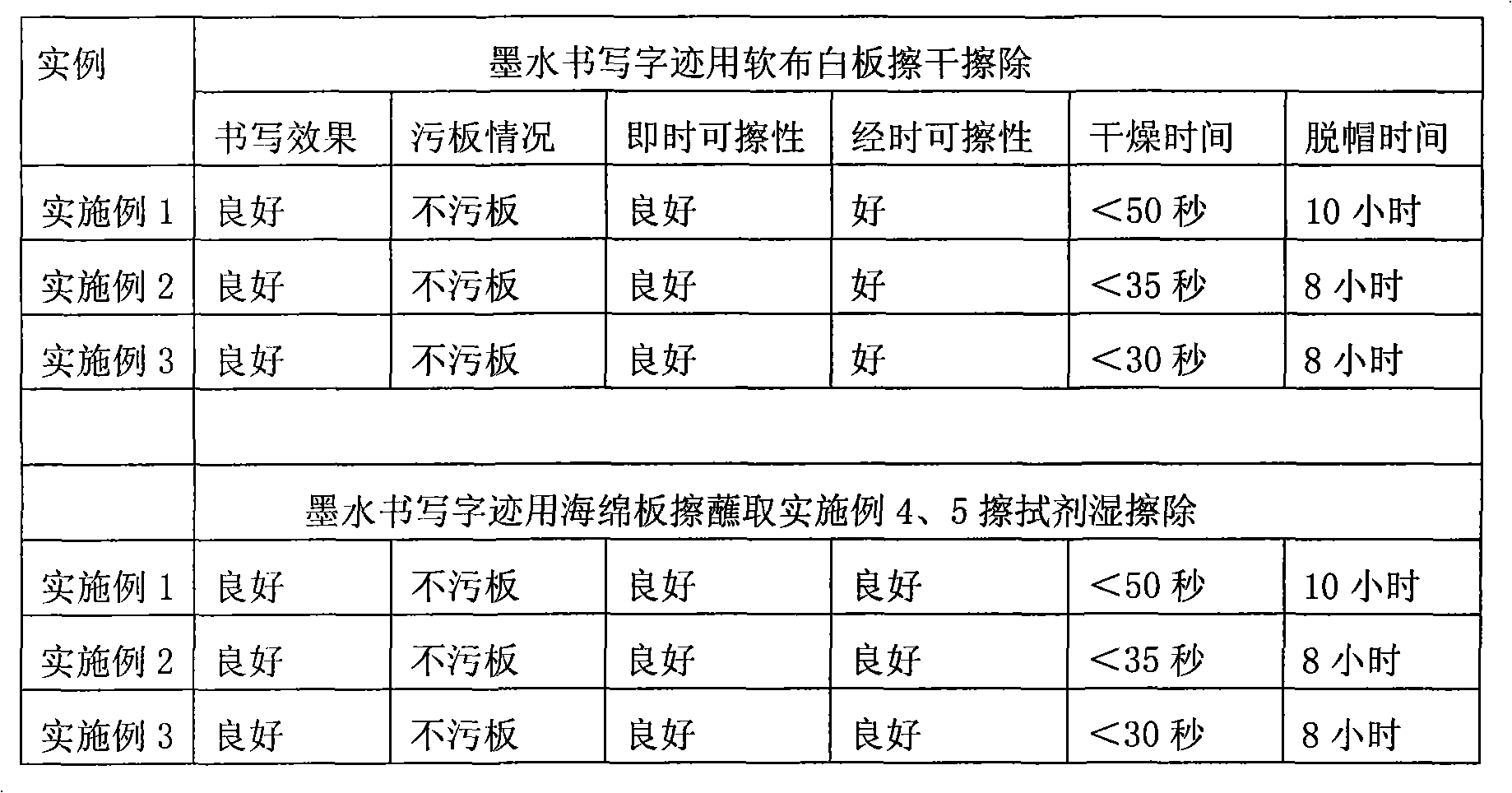

Examples

Embodiment 1

[0018] Take 69.95g of distilled water, 2g of polyvinyl alcohol resin, 3g of nonionic fluorocarbon surfactant, 5g of magnesium sulfate, 2g of castor oil, 1g of propylene glycol, 2g of polyethylene glycol, 2g of polyoxyethylene castor oil, 53g of acid green, and 10g of ethanol , isothiazolinone 0.05g.

[0019] Preparation: Add polyvinyl alcohol resin to 5 times the weight of distilled water, heat to 90°C and stir until the resin is completely dissolved, then stop heating. Acid Green 5 was added under stirring to form a solution (1). Slowly add non-ionic fluorocarbon surfactant, castor oil, propylene glycol, polyethylene glycol, polyoxyethylene castor oil, and isothiazolinone into ethanol under stirring to form solution (2), then mix solution (1 ) and solution (2) were stirred and mixed, and finally the remaining distilled water and magnesium sulfate were added, fully stirred and mixed evenly to obtain green water-based whiteboard pen ink.

Embodiment 2

[0021] Take 42.95g of distilled water, 3g of hydroxypropyl methylcellulose, 2g of nonionic fluorocarbon surfactant, 4g of magnesium sulfate, 5g of castor oil, 1g of propylene glycol, 4g of polyethylene glycol, 3g of polyoxyethylene castor oil, and acid fuchsin 5g, methanol 10g, ethanol 20g, isothiazolinone 0.05g.

[0022] Preparation: add hydroxypropyl methylcellulose to 5 times the weight of distilled water, stir to dissolve it completely, and add acid fuchsin under stirring to form a solution (1). Slowly add non-ionic fluorocarbon surfactant, castor oil, propylene glycol, polyethylene glycol, polyoxyethylene castor oil, and isothiazolinone into ethanol and methanol to form a solution (2), and then dissolve the solution (1) Stir and mix with solution (2), and finally add remaining distilled water and magnesium sulfate, fully stir and mix evenly to obtain red water-based whiteboard pen ink.

Embodiment 3

[0024] Take 34.9g of distilled water, 4g of polyvinylpyrrolidone, 1g of nonionic fluorocarbon surfactant, 3g of zinc sulfate, 3g of castor oil, 1g of propylene glycol, 3g of polyethylene glycol, 3g of polyoxyethylene castor oil, 7g of methyl violet, propanol 10g, 30g ethanol, 0.1g isothiazolinone.

[0025] Preparation: Add polyvinylpyrrolidone to 5 times the weight of distilled water, stir to dissolve it completely, and add methyl violet under stirring to form a solution (1). Slowly add nonionic fluorocarbon surfactant, castor oil, propylene glycol, polyethylene glycol, polyoxyethylene castor oil, and isothiazolinone into ethanol and propanol to form a solution (2), and then The solution (1) and the solution (2) are stirred and mixed, and finally the remaining distilled water and zinc sulfate are added, fully stirred and mixed evenly to obtain a purple water-based whiteboard pen ink.

[0026] Prepare wipes

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com