Preparation method of hydroxy fluorine-containing water-based acrylic resin-polyurethane hybrid

A technology of water-based acrylic and water-based polyurethane, applied in the direction of coating, etc., can solve problems such as high cost, and achieve the effects of cost reduction, excellent weather resistance, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

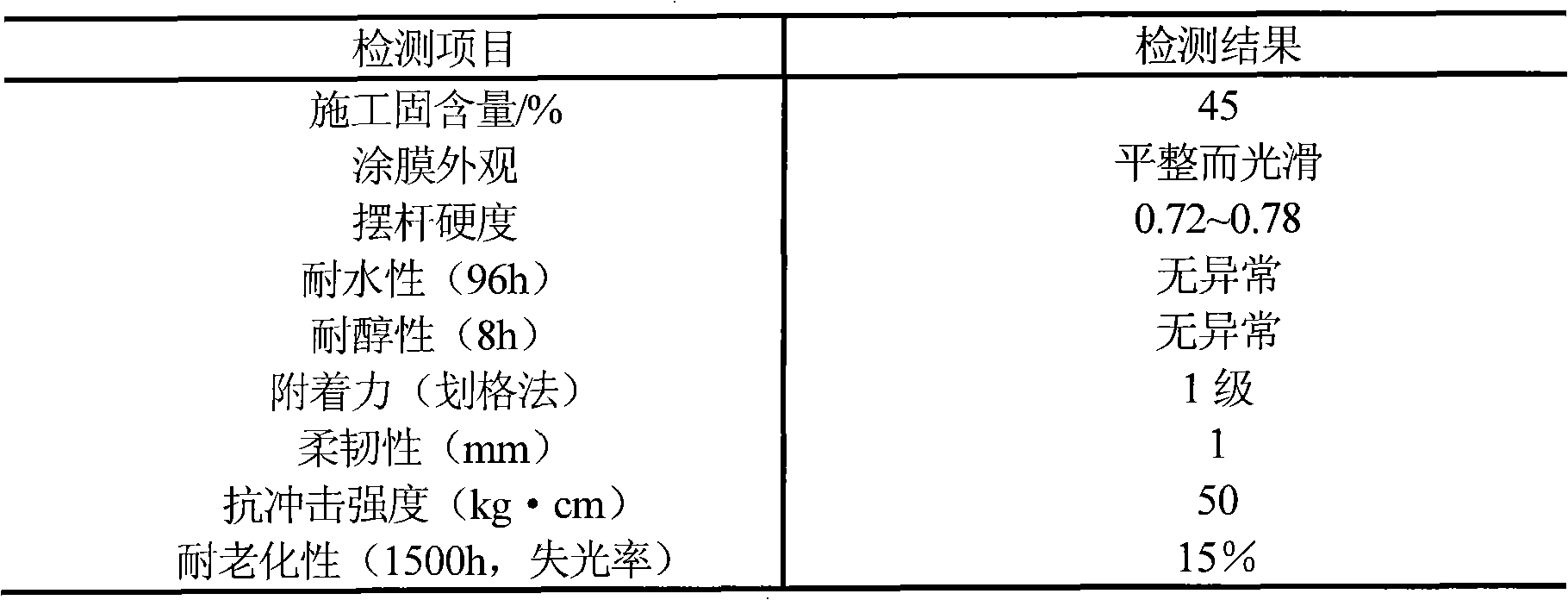

Examples

Embodiment 1

[0026](1) Under the protection of nitrogen, 26.80gAD (adipic acid), 3.460gBEPD (2-butyl-2-ethyl-1,3-propanediol), 6.300gTMPME (trimethylolpropane monoallyl ether) ), 14.85g NPG (neopentyl glycol), and 5.500g xylene were added to a reactor equipped with a stirrer, a thermometer, and a water separator, and the temperature was raised to 140°C. Stirring was started, and the temperature was gradually raised to 190°C over 4 hours. After the reaction at 190°C for 1 hour, start to measure the acid value; when the acid value drops to 5mgKOH / g resin, remove the xylene in a vacuum at 100°C, the vacuum degree is ≥0.045kPa, cool down to 40°C, filter, and discharge to obtain Unsaturated hydroxyl terminated polyester. Its hydroxyl value is 112 mgKOH / g resin; the functionality is 2.

[0027] (2) Add 20.20g of the above-mentioned unsaturated hydroxyl-terminated polyester, 1.750g of 1,4-butanediol, and 2.650g of dimethylol propionic acid into a reactor with a stirrer and a thermometer, and the...

Embodiment 2

[0037] (1) Under nitrogen protection, mix 15.80gAD (adipic acid), 5.82gMA (maleic anhydride), 6.820gCHDM (1,4-cyclohexanedimethanol), 6.800gTMPME (trimethylolpropane monoallyl Base ether), 15.78g NPG (neopentyl glycol), and 5.320g xylene were added to a reactor equipped with a stirrer, a thermometer, and a water separator, and the temperature was raised to 140°C, stirring was started, and the temperature was gradually raised to 190°C over 4 hours. After heat preservation at 190°C for 1 hour, start to measure the acid value; when the acid value drops to 5mgKOH / g resin, vacuum out xylene at about 100°C, the vacuum degree is ≥0.045kPa, cool down, filter, and discharge to obtain the unsaturated end Hydroxy polyester. Its hydroxyl value is 112 mgKOH / g resin; the functionality is 2.

[0038] (2) Add 20.12g of the above-mentioned unsaturated hydroxyl-terminated polyester, 5.100g of neopentyl glycol, and 3.580g of dimethylol butyric acid into a reactor with a stirrer and a thermomete...

Embodiment 3

[0048] (1) Under nitrogen protection, 12.87gAD (adipic acid), 8.000gMA (maleic anhydride), 6.220gCHDM (1,4-cyclohexanedimethanol), 6.560gTMPME (trimethylolpropane monoallyl base ether), 15.78g HDO (1,6-hexanediol), and 4.940g xylene were added to the reactor equipped with a stirrer, thermometer, and water separator, the temperature was raised to 140°C, stirring was started, and the temperature was gradually raised to 190°C in 4 hours. ℃. After heat preservation at 190°C for 1 hour, start to measure the acid value; when the acid value drops to 5mgKOH / g resin, vacuum out xylene at about 100°C, the vacuum degree is ≥0.045kPa, cool down, filter, and discharge to obtain the unsaturated end Hydroxy polyester. Its hydroxyl value is 112 mgKOH / g resin; the functionality is 2.

[0049] (2) Add 22.25g of the above-mentioned unsaturated hydroxyl-terminated polyester, 5.100g of 1,6-hexanediol, and 3.520g of dimethylol propionic acid into a reactor with a stirrer and a thermometer, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com