Method for extracting essential oil of taxus media

A technique of Taxus mandiensis and Taxus mandiensis, which is applied in the field of extracting the essential oil of Taxus mandiensis by steam distillation, can solve the problems such as no report of the essential oil of Taxus mandiensis, and is convenient for large-scale production, The effect of improving osmotic pressure and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

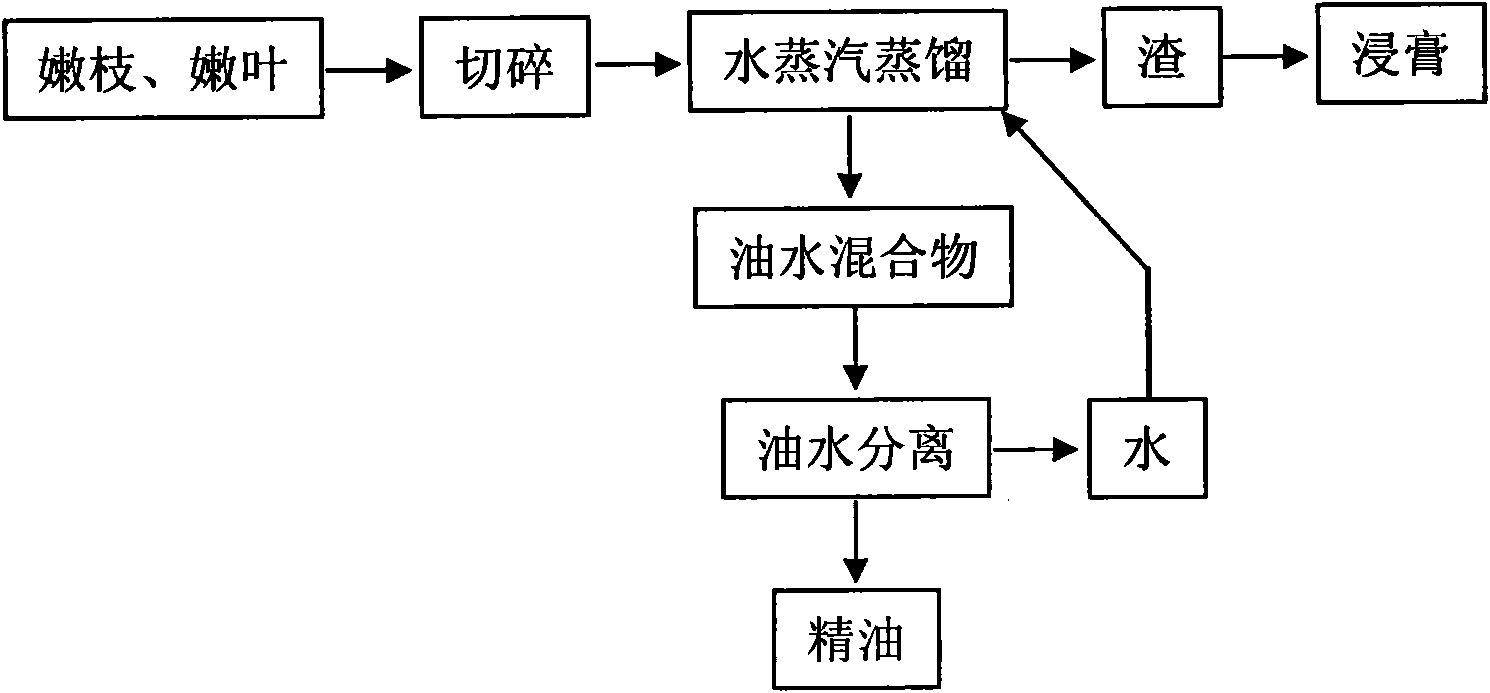

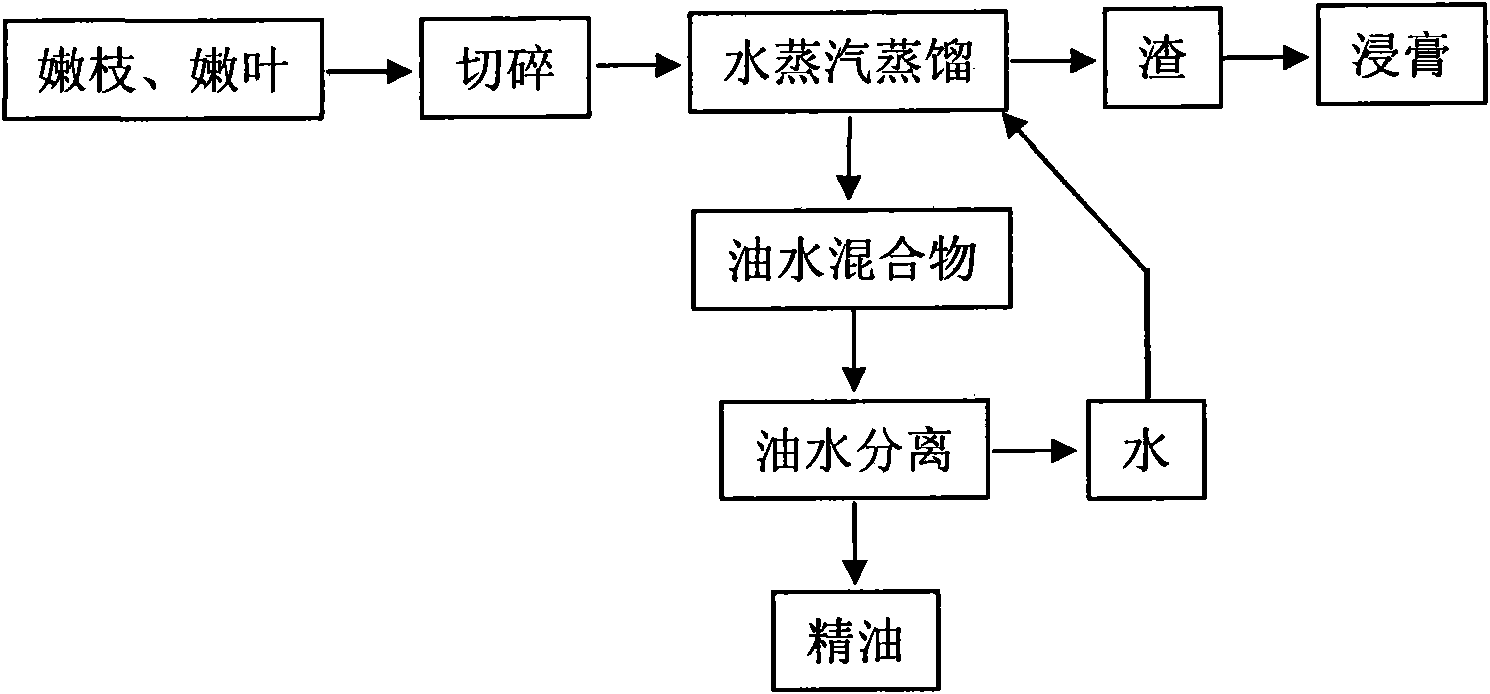

Method used

Image

Examples

Embodiment 1

[0013] Step 1: Raw material pretreatment: take 500 grams of fresh leaves of Taxus chinensis from which impurities have been removed, and pulverize them with a pulverizer to obtain raw material powder;

[0014] Step 2: Steam distillation: Stir the raw material powder and 15 grams of salt evenly, put it into a distillation bottle, and put it into steam distillation for 2.5 hours;

[0015] Step 3: oil-water separation: the collected oil-water mixture was centrifuged at a high speed of 20,000 rpm for 10 minutes in a centrifuge to obtain 2.3 grams of yew essential oil.

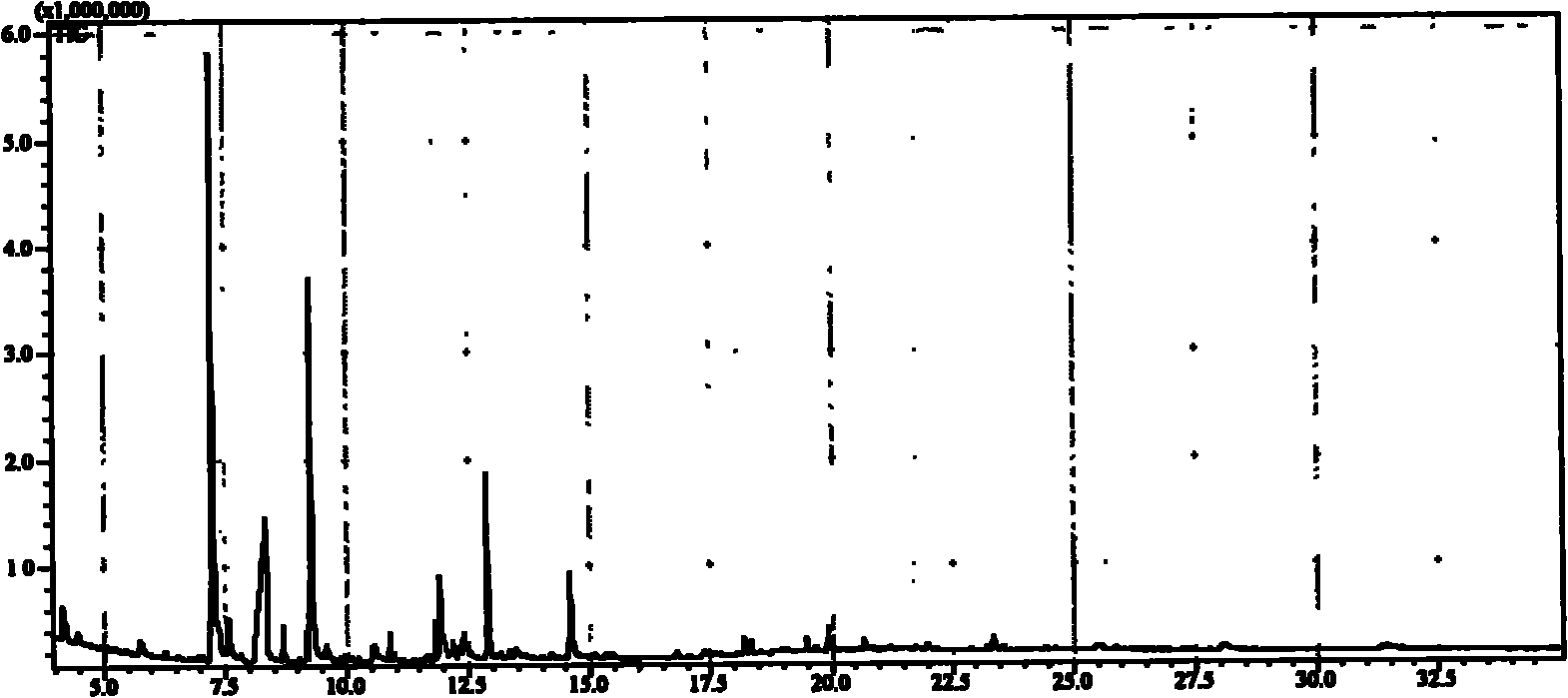

[0016] The obtained yew essential oil product is light yellow, transparent liquid at normal temperature, has a unique fragrance, and is volatile; the specific gravity, specific rotation and refractive index are 0.891g / ml, +100.06 and 1.476, respectively. figure 2 The GC-MS total ion chromatogram of the essential oil shows that the yew essential oil contains unsaturated compounds such as phenols, aldehydes, and lac...

Embodiment 2

[0018] Step 1: raw material pretreatment: take 2000 grams of fresh twigs and young leaves of Taxus chinensis from which impurities have been removed, and chop them into pieces of about 1.5 cm with a knife to obtain raw material pieces;

[0019] Step 2: Steam distillation: Stir the raw material fragments with 40 grams of salt evenly, put them into a distillation bottle, and pass through steam distillation for 3.0 hours;

[0020] Step 3: oil-water separation: the collected oil-water mixture was separated with a separatory funnel to obtain 5.7 grams of yew essential oil.

Embodiment 3

[0022] Step 1: Raw material pretreatment: take 200 kg of fresh twigs and young leaves of Taxus chinensis, and chop them into pieces of about 2 cm with a cutting machine to obtain raw material pieces;

[0023] Step 2: Steam distillation: put the raw material fragments and 5 kg of salt into the distillation pot, pass through the steam distillation treatment for 0.5 hours, then turn on the stirring paddle, steam treatment while stirring for 0.5 hours, then stop stirring and continue the steam treatment for 2.5 hours;

[0024] Step 3: oil-water separation: the collected oil-water mixture was left to separate with an oil-water separator to obtain 318 grams of yew essential oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com