Anti-corrosive pigment and preparation method thereof

A technology of anti-rust pigments and raw materials, which is applied in anti-corrosion coatings, pigment pastes, dyeing organic silicon compounds, etc. It can solve the problems of anti-rust performance, salt water resistance and storage stability, and achieve low price and excellent anti-corrosion. Rust performance, comprehensive performance, good fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

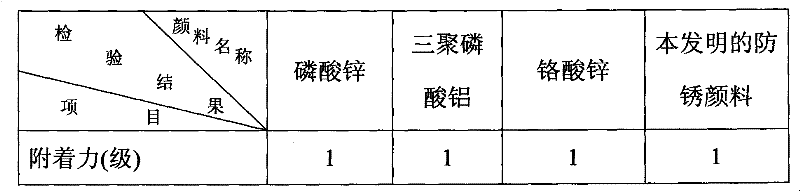

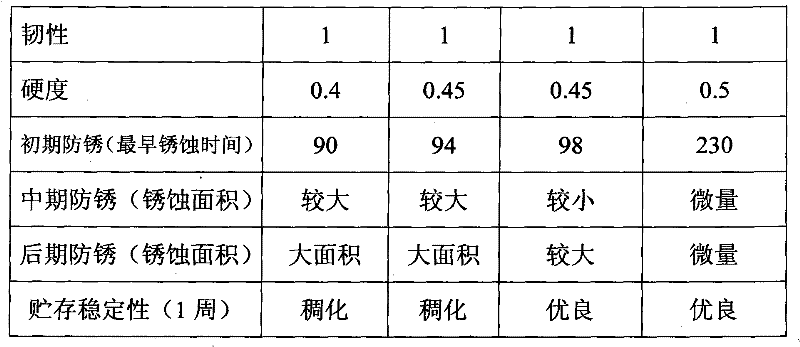

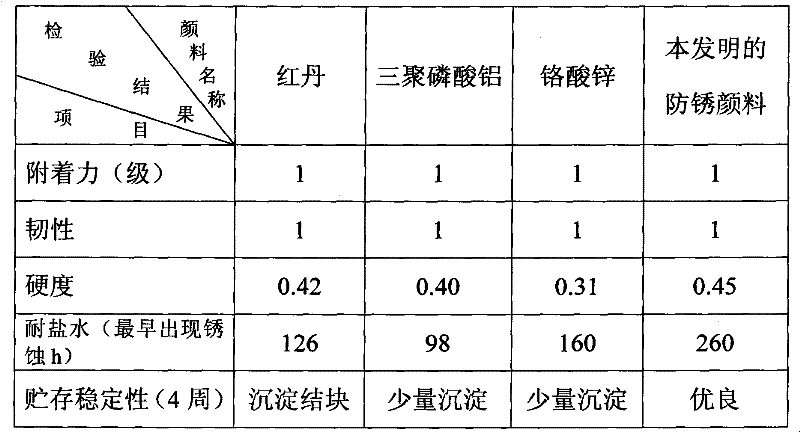

Examples

Embodiment 1

[0025] Slowly add 50% zinc sulfate solution to 10% phytic acid and 7% tannic acid mixed aqueous solution, stir while adding, then adjust pH to 5-6 with caustic alkali or ammonia water, and continue stirring for 10 minutes to form Zinc phytate and zinc tannate, mix zinc phytate and zinc tannate with mica or micaceous iron oxide in a weight ratio of 2:3, stir for 60 minutes to make it evenly mixed, wash with water, dry and grind to a particle size of 0.5-4μm, to obtain antirust pigments containing zinc phytate, zinc tannate and mica or micaceous iron oxide.

Embodiment 2

[0027] Slowly add about 30% aluminum sulfate solution to 10%~20% phytic acid and 7%~10% tannic acid mixed aqueous solution, stir while adding, and then use caustic alkali or ammonia water to adjust the pH to 3.5~ 4.0, continue stirring for 16 minutes to generate aluminum phytate and aluminum tannate, then mix aluminum phytate and aluminum tannate with mica or mica iron oxide in a weight ratio of 1:6, and stir for 120 minutes to make it Mix evenly, wash with water, dry, and grind to a particle size of 0.5-4 μm to obtain an antirust pigment containing aluminum phytate, aluminum tannate, mica or mica iron oxide.

Embodiment 3

[0029] Slowly add 10% to 30% ferric chloride solution to 10% to 20% phytic acid and 5% to 10% tannic acid mixed aqueous solution, stir while adding, and then adjust the pH with caustic alkali or ammonia water =5, continue to stir for 10 minutes to generate iron phytate and iron tannate double salt, then mix iron phytate and iron tannate double salt with mica or micaceous iron oxide in a weight ratio of 1:1, after stirring After 200 minutes, make it evenly mixed, wash with water, dry, and grind to a particle size of 0.5-4 μm to obtain an antirust pigment containing iron phytate and iron tannate double salt and mica or micaceous iron oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com