Method for preparing three-dimensional macro carbon nanometer pipe network

A carbon nanotube, three-dimensional technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of limiting the application of carbon nanotube materials, the electrical conductivity and mechanical properties cannot be exerted, and achieve good application prospects, The effect of improved electrical conductivity and mechanical properties, and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

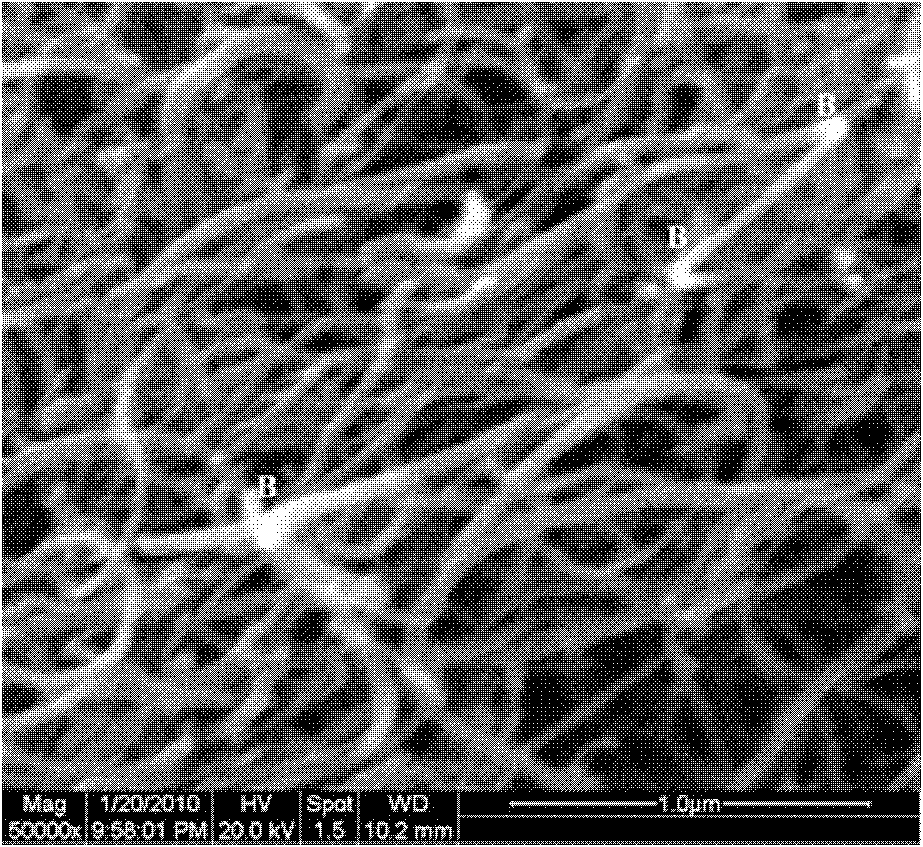

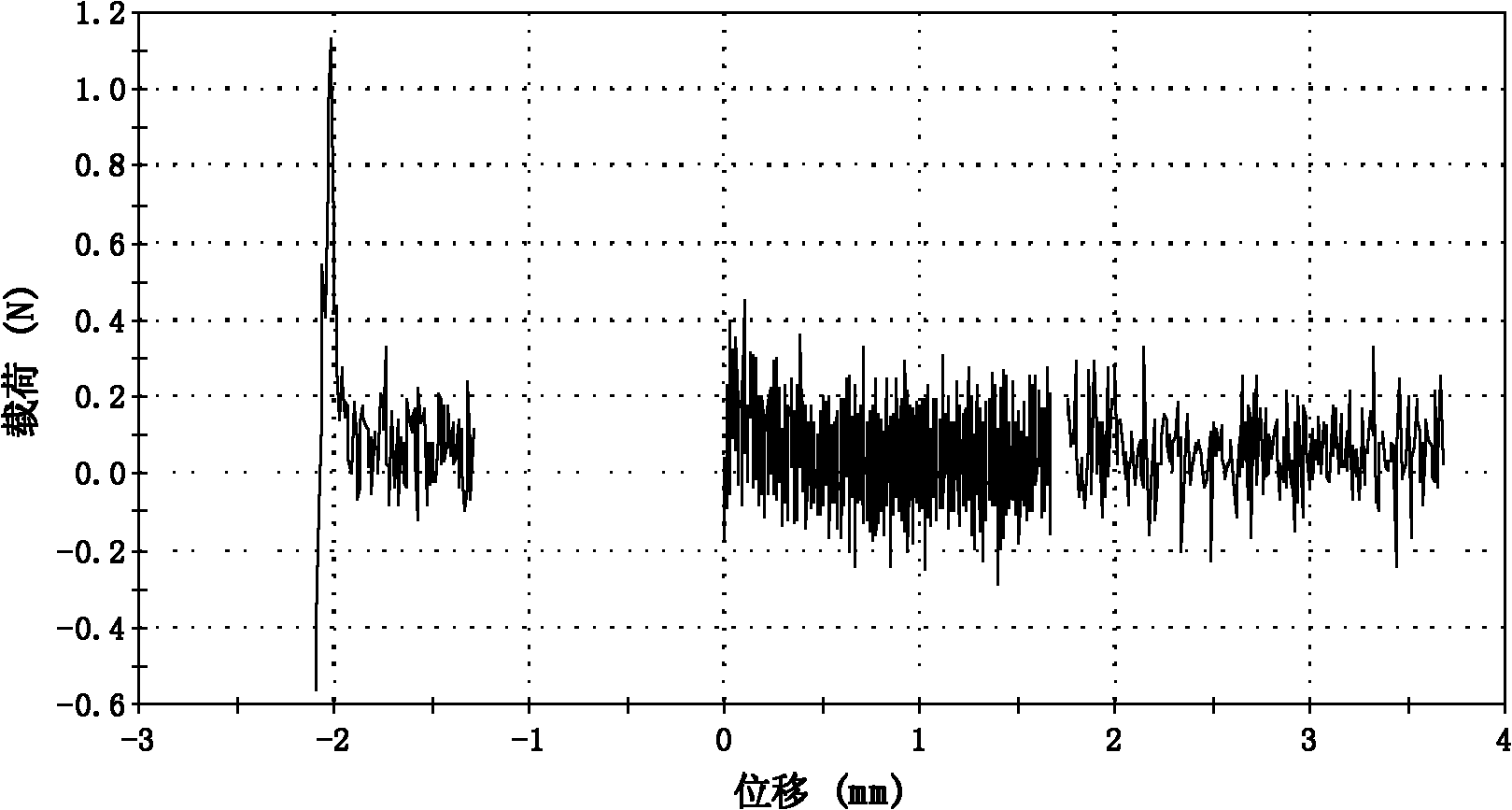

[0030] A specific embodiment of the present invention is: a method for preparing a three-dimensional macroscopic carbon nanotube network, the method of which is:

[0031] A. Purify the carbon nanotube powder with sulfuric acid, then ultrasonically disperse, filter under pressure, and dry in vacuum to obtain a carbon nanotube network precursor;

[0032] B. The carbon nanotube network precursor supports the catalyst for connection. In this example, ferric nitrate is used as the catalyst, and the carbon nanotube network precursor is immersed in the ferric nitrate solution, so that the carbon nanotube network precursor is completely infiltrated, and then the carbon nanotube network precursor can be loaded with the catalyst iron nitrate for connection.

[0033] C. Place the catalyst-loaded carbon nanotube network precursor in the quartz tube of the tubular resistance furnace. During the heating process, pass argon gas into the quartz tube to discharge the air in the tube; change th...

Embodiment 2

[0035] The method of this example is basically the same as that of Example 1, the difference is only:

[0036] The catalyst loaded in step B for connection is a mixture of iron nitrate and nickel nitrate (mass ratio 1:1).

[0037] In the C step, the temperature of feeding hydrogen is 950°C, the holding time is 150min, the temperature during heat treatment reaction is 900°C, what is feeding is natural gas, and the reaction (holding time) time is 150min.

Embodiment 3

[0039] The approach in this example is:

[0040] A. Purifying the carbon nanotube powder with nitric acid, then ultrasonically dispersing, filtering at normal pressure, and vacuum drying to obtain a carbon nanotube network precursor;

[0041] B. The carbon nanotube network precursor supports the catalyst for connection. This example catalyst selects nickel, adopts the electrochemical deposition method to load catalyst metal nickel, and its specific parameters are: the carbon nanotube network precursor is used as the working electrode, with a constant potential of 2.05V in the plating solution (every 50mL solution contains: nickel sulfate 15.00 g, nickel chloride 2.00g, boric acid 2.00g, sodium lauryl sulfate 0.05g, sodium saccharin 0.02g), carry out DC electrochemical deposition for 5min (minutes), then rinse with secondary deionized water and keep warm at 100°C 30min, that is, metal nickel is deposited on the carbon nanotube network precursor.

[0042] C. Place the catalyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com