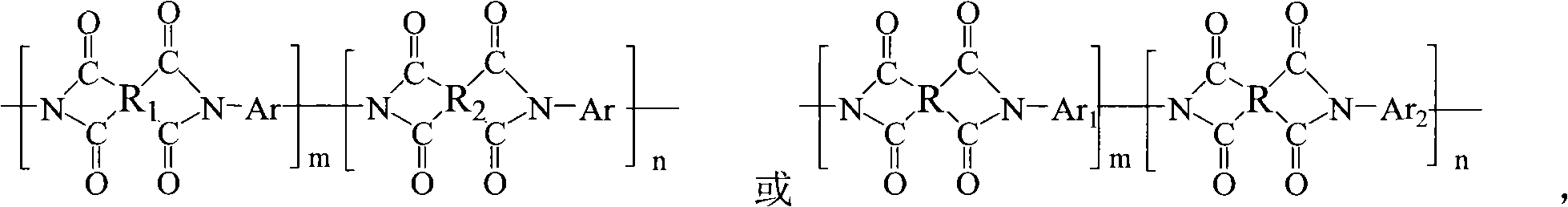

New type fluorine-containing copolyimide and preparation method thereof

A technology of thermal imidization of fluorine-containing copolymerized polyimide, which is applied in the field of new fluorine-containing copolymerized polyimide and its preparation, and can solve problems such as limited application and difficulty in product processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

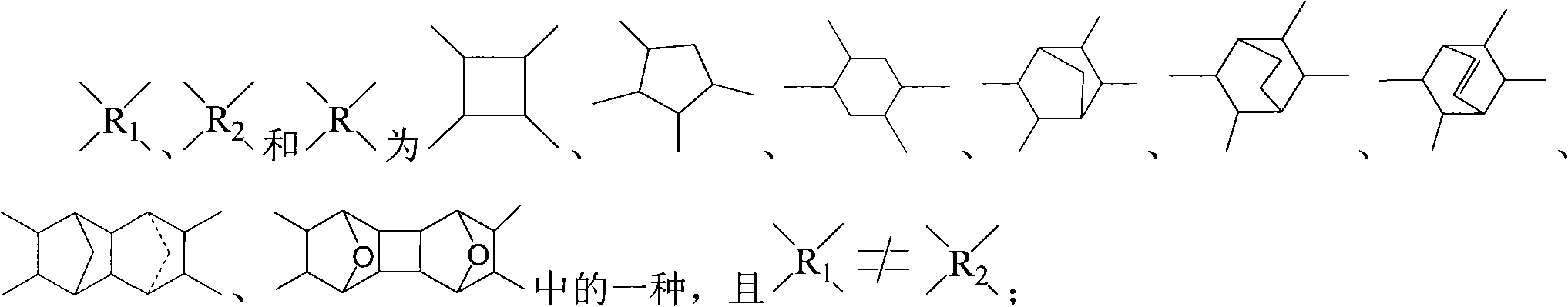

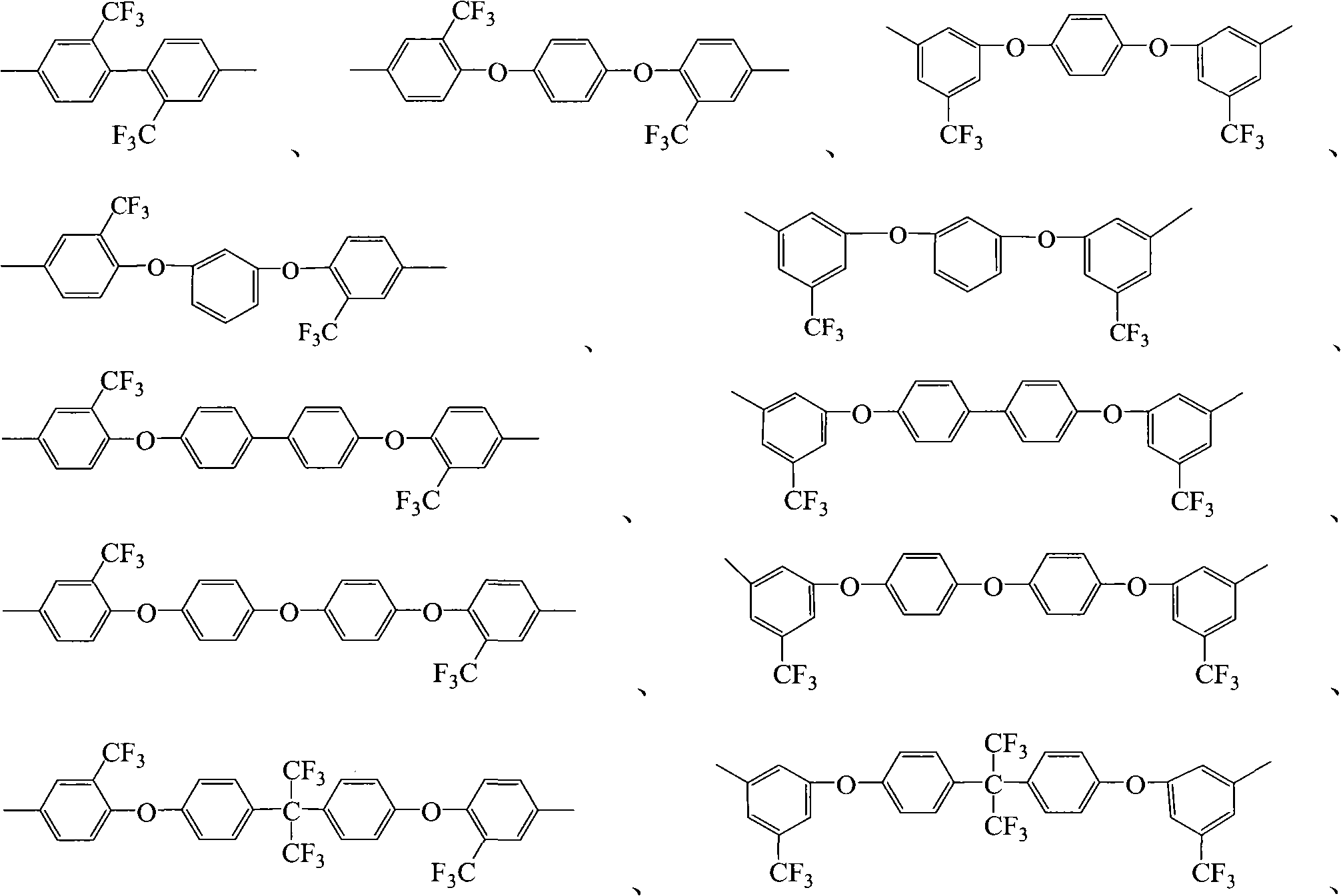

Method used

Image

Examples

Embodiment 1

[0037] First, in a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 2.1417 g (5 mmol) of 1,4-bis(4-amino-2-trifluoromethylphenoxy)benzene was dissolved in 20.76 In mLDMF, add 1,2,3,4-cyclobutanetetracarboxylic dianhydride 0.4903g (2.5mmol) and 1,2,3,4-cyclobutane-symmetric (3,6- Oxygen bridge-1,2,3,6-tetrahydrobenzene-1,2-dimethylformic anhydride) 0.8307g (2.5mmol), stir the above mixed solution under nitrogen atmosphere, react at 0~25℃ for 15~25h , Obtain a uniform and viscous polyamic acid (PAA) solution, the solid content of PAA by weight is 15wt%, and the intrinsic viscosity is 1.20dL / g. The PAA solution was coated on a clean glass plate, placed in a drying oven with nitrogen protection, and the temperature was raised according to the following program: 80°C 2hrs, 120°C 1hr, 150°C 1hr, 200°C 1hr, 250°C 1hr, 280°C 0.5hr. After the temperature dropped to room temperature, the glass plate was taken out and placed in warm water to re...

Embodiment 2

[0041] First, in a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 1.3011 g (2.5 mmol) of 4,4'-bis(4-amino-2 trifluoromethylphenoxy) diphenyl ether and 0.8006 g (2.5 mmol) of 2,2'-bistrifluoromethyl-4,4'-diaminobiphenyl were dissolved in 18.48 mL of DMF, and after it was completely dissolved, 1,2,3,4-cyclobutane was added Tetracarboxylic dianhydride 0.9806g (5mmol), stir the above mixed solution under a nitrogen atmosphere, react at 0-25°C for 15-25h to obtain a uniform and viscous polyamic acid (PAA) solution, the solid content of PAA by weight It is 15wt%, and the intrinsic viscosity is 1.25dL / g. The PAA solution was coated on a clean glass plate, placed in a drying oven with nitrogen protection, and the temperature was raised according to the following program: 80°C 2hrs, 120°C 1hr, 150°C 1hr, 200°C 1hr, 250°C 1hr, 280°C 0.5hr. After the temperature dropped to room temperature, the glass plate was taken out and placed in warm water...

Embodiment 3

[0045] First, in a three-necked reaction flask equipped with a stirrer, a thermometer and a nitrogen inlet, 2,2-bis[4-(4-amino-2trifluoromethylphenoxy)phenyl]hexafluoropropane 3.2723 g (5mmol) was dissolved in 28.94mLDMF, and after it was completely dissolved, 0.2242g (1mmol) of 1,2,4,5-cyclohexanetetracarboxylic dianhydride and 1,2,3,4-cyclobutane- Symmetrical (3,6-oxo-1,2,3,6-tetrahydrobenzene-1,2-dimethylformic anhydride) 1.3290g (4mmol), stir the above mixed solution under nitrogen atmosphere, at 0~25℃ The reaction was carried out for 15-25 hours to obtain a uniform and viscous polyamic acid (PAA) solution, the solid content of PAA by weight was 15wt%, and the intrinsic viscosity was 1.18dL / g. The PAA solution was coated on a clean glass plate, placed in a drying oven with nitrogen protection, and the temperature was raised according to the following program: 80°C 2hrs, 120°C 1hr, 150°C 1hr, 200°C 1hr, 250°C 1hr, 280°C 0.5hr. After the temperature dropped to room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com