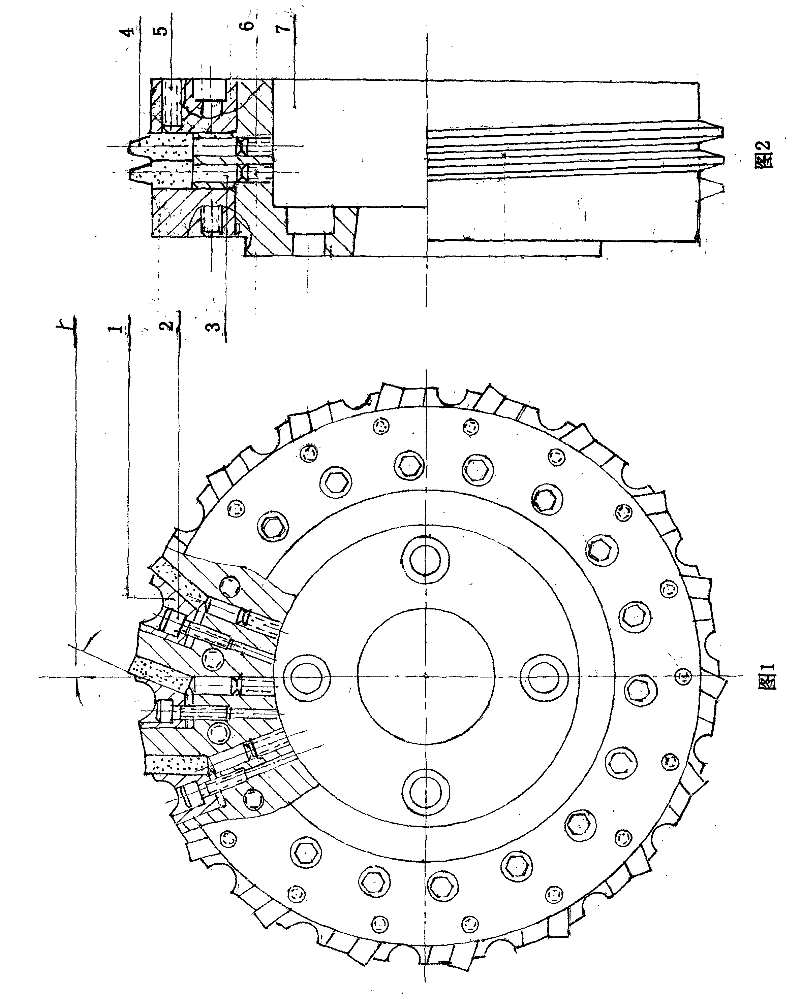

Hard-surface gear hobbing processing device

A processing device and hard tooth surface technology, applied in the direction of belts/chains/gears, gear teeth, components with teeth, etc., can solve the problem that the Archimedes worm gear is not suitable for high-speed operation, the machine tool is a vertical structure with a high center of gravity, No problems such as lubricating oil wedges can be generated, and the effects of reducing tooth chipping, natural vibration frequency and center of gravity can be reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

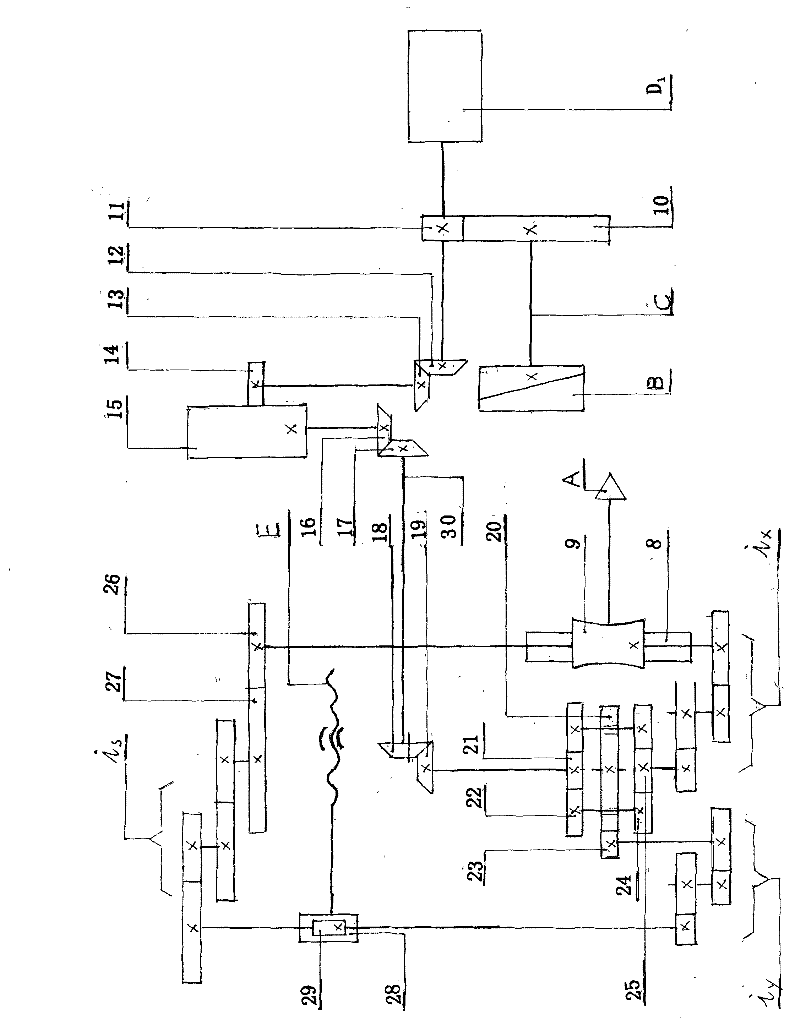

[0056] Figure 5 middle:

[0057] 1) Extremely shorten the main motion transmission chain

[0058] From main motor D 1 To the tool spindle C, is the main motion transmission chain, Figure 5 Adopt a pair of reduction gear tool main shaft deceleration driven gear 10 and tool main shaft deceleration driving gear 11, the speed ratio is 18 / 85. main motor D 1 4 poles are selected, the synchronous speed is 1500 rpm, and the speed is adjusted to 1000 rpm to 2000 rpm by frequency conversion. The diameter of the hard tooth surface gear hob is 300 mm, and the cutting speed is guaranteed to be 200 m / min to 400 m / min. point.

[0059] 2) Adopt horizontal structure

[0060] The workpiece spindle A adopts a horizontal type, cancels the column, and feeds the tool holder in the horizontal direction, which reduces the center of gravity of the machine tool and improves the static rigidity of the machine tool.

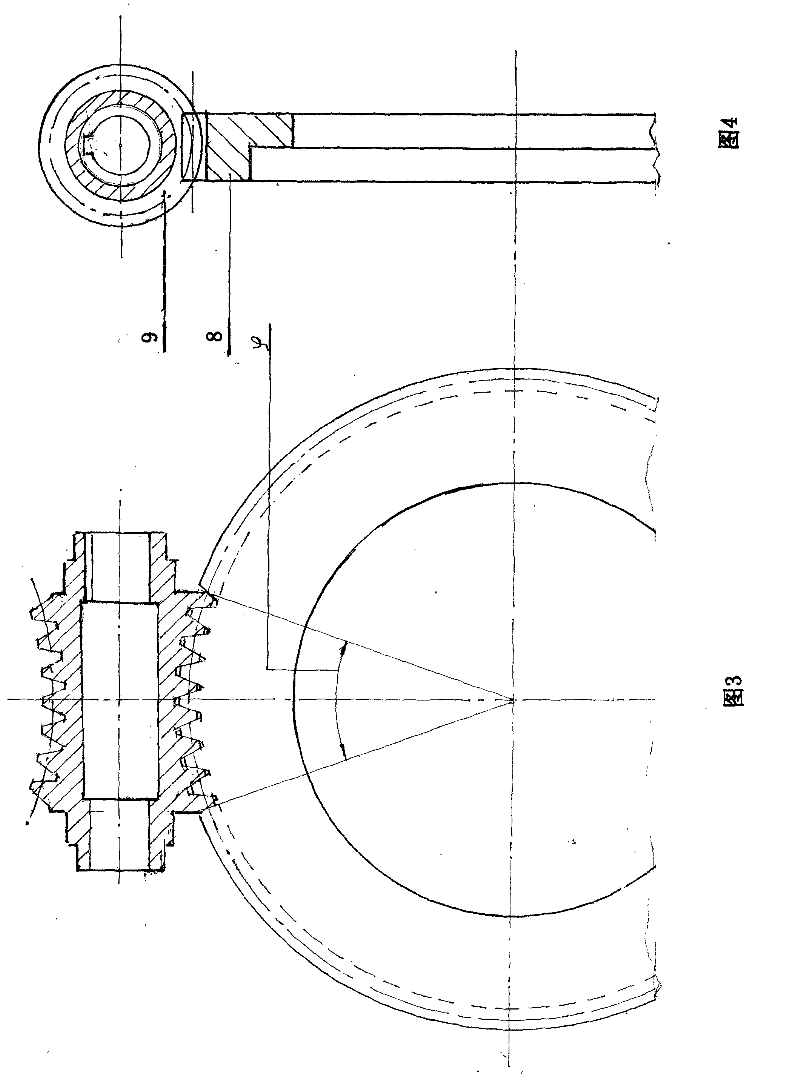

[0061] 3) The plane worm wheel 8 and the plane enveloping worm 9 are used as t...

Embodiment 2

[0080] Image 6 middle:

[0081] In this embodiment, electric shaft transmission is used to replace the high-speed transmission elements, and the specific implementation plan is: Image 6 The main motor D in 1 and workpiece spindle drive motor D 2 The synchronous motors with the same synchronous rotating speed are adopted, and the two motors are like one shaft, and the gears 12, 13, 14, 15, 16, 17, 18, 19 and the long spline shaft 30 are canceled in the middle.

[0082] Since the main motor D 1 with workpiece spindle drive motor D 2 As a shaft, the indexing hanging wheel i x , differential hanging wheel i y and feed hanger i s The applied calculation formula is the same as that of the first embodiment of the hard-tooth surface gear hobbing machine.

[0083] This embodiment uses two AC synchronous motors instead of mechanical transmission. From theoretical analysis: when the external power supply voltage and processing load fluctuate, it will affect the synchronous char...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com