Composite catalyst, preparation and application thereof

A composite catalyst and reaction technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of easy deactivation of catalysts, decreased catalyst activity, and failure to adapt to cycles Economic requirements and other issues, to achieve the effect of avoiding difficult operation, narrow particle size distribution, and meeting the requirements of catalyst activity and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Nano Zr(OH) 4 Preparation of hydrosols

[0078] First prepare the molar concentration of about 0.20mol / L ZrOCl 2 Aqueous solution, under the condition of continuous stirring, 25% ammonia water is used as precipitating agent, the ZrOCl that will prepare 2 The aqueous solution is added dropwise into the precipitating agent while controlling the pH value of the solution to be about 8-11. After the dropwise addition, continue to stir for 0.5 hours, then leave it to age for 3 hours to obtain Zr(OH) 4 Hydrosol. Zr(OH) 4 The hydrosol is washed repeatedly with deionized water until there is basically no chloride ion, and Zr(OH) 4 Hydrogel, filtered by suction, set aside.

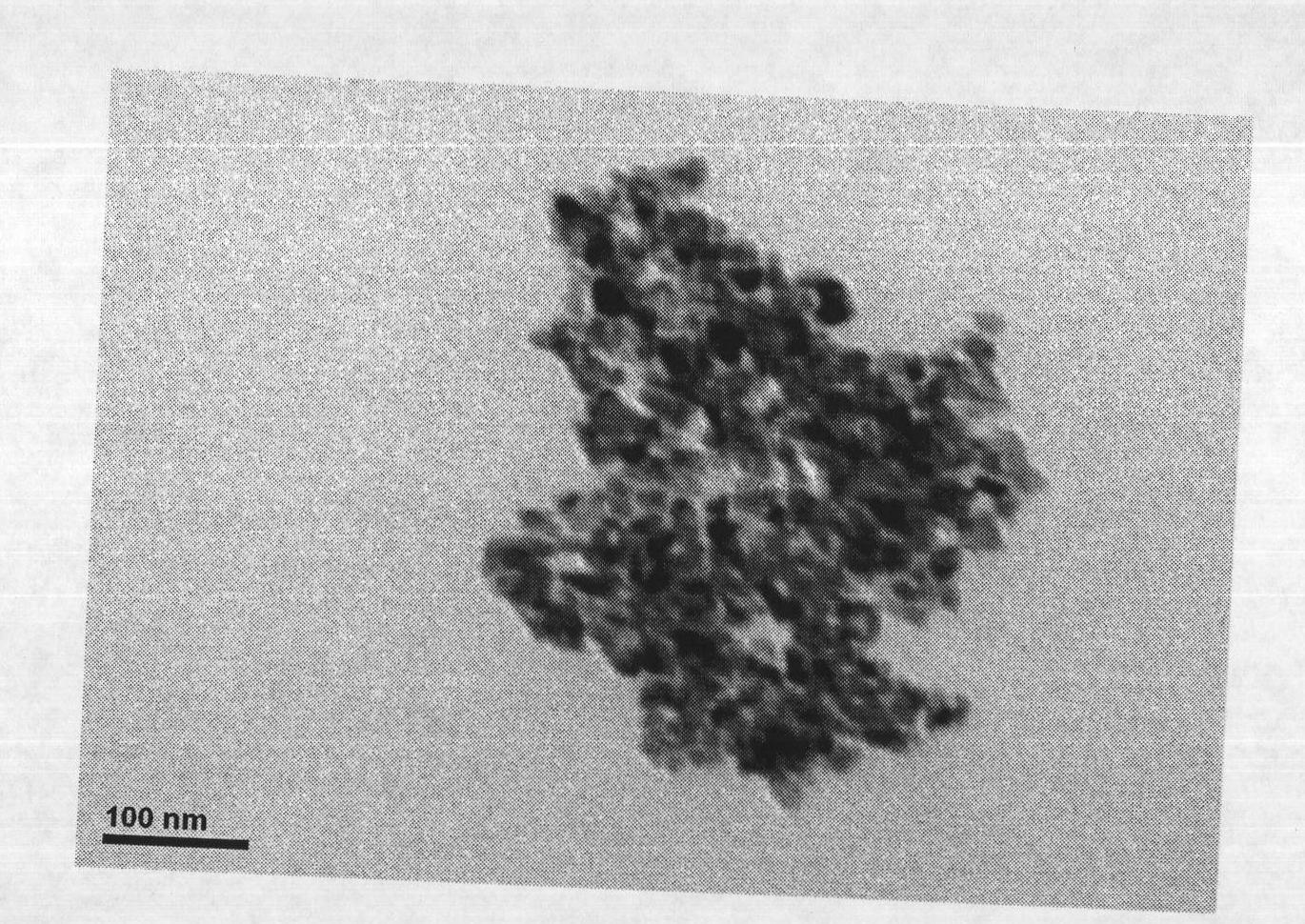

[0079] The resulting Zr(OH) 4 Nano-ZrO obtained after hydrogel drying 2 Characterized by transmission electron microscopy, as figure 1 Shown, ZrO 2 The particle size is 2-20nm.

[0080] Composite catalyst preparation

[0081] Add 60g nano-calcium carbonate in the beaker, stir after adding deionize...

Embodiment 2

[0099] Composite catalyst preparation

[0100] Take 10.47g ZrOCl 2 ·8H 2 The molar concentration of O is about 0.20mol / L ZrOCl 2 Aqueous solution, the method described in embodiment 1 makes Zr(OH) 4 Hydrogel, then add 60.00g nano calcium carbonate in the beaker, stir after adding deionized water, the Zr(OH) that will make 4 The hydrogel is added to the nano-calcium carbonate, and at the same time, 260.00 g of aluminum sol with a solid content of 10% is added, mixed evenly, dried, extruded, and calcined into granules. Finally, 49.57g of nickel nitrate hexahydrate solution was added dropwise to the above shaped particles by equal volume impregnation method, impregnated at room temperature for 36 hours, filtered, dried, calcined at 500°C for 3 hours, cooled to room temperature for later use. The prepared composite catalyst ZrO 2 The mass content is 4%. The catalyst is designated as C-2.

[0101] Application of Composite Catalysts in Carbon Dioxide Reactive Adsorption Enhan...

Embodiment 3

[0104] Composite catalyst preparation

[0105] Take 20.94g ZrOCl 2 ·8H 2 The molar concentration of O is about 0.20mol / L ZrOCl 2 Aqueous solution, the method described in embodiment 1 makes Zr(OH) 4 Hydrogel, then add 60.00g nano calcium carbonate in the beaker, stir after adding deionized water, the Zr(OH) that will make 4 The hydrogel is added to the nano-calcium carbonate, and at the same time, 220.00 g of aluminum sol with a solid content of 1% is added, mixed evenly, dried, extruded, and calcined into granules. Finally, 49.57g of nickel nitrate hexahydrate solution was added dropwise to the above shaped particles by equal volume impregnation method, impregnated at room temperature for 72 hours, filtered, dried, calcined at 500°C for 3 hours, cooled to room temperature for later use. The prepared composite catalyst ZrO 2 The mass content is 8%. The catalyst is designated as C-3.

[0106] Application of Composite Catalysts in Carbon Dioxide Reactive Adsorption Enhanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com