Heat radiator with composite structure and preparation method thereof

A composite structure and heat sink technology, applied in heat exchange equipment, lighting and heating equipment, electric solid devices, etc., can solve problems such as suboptimal heat dissipation efficiency, increased production costs, and decreased directional thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

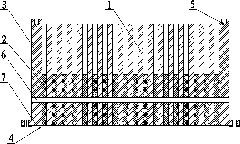

[0035] A preparation method of a composite structure graphite radiator, comprising the following steps:

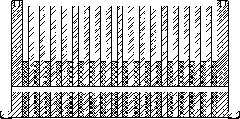

[0036] 1) impregnating expandable graphite with paraffin in a vacuum impregnation box, the amount of paraffin impregnated is 85%±5% of the total weight of the finished product, and compacted to make a plurality of long fins 1;

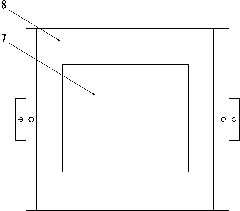

[0037] 2) The thermal conduction layer 7 and the plurality of short fins 2 are made of a flexible graphite plate with a density of 1.1-1.7g / cm3;

[0038] 3) A plurality of long fins 1 and a plurality of short fins 2 are arranged staggeredly, one end is aligned, and the clamping device is used to install firmly. Except for the aligned end faces, the other three end faces are sealed with PET single-sided adhesive film;

[0039] 4) Polish the aligned end faces, and install the heat conducting layer 7 on the end faces.

[0040] The flexible graphite plate adopts the expanded graphite foam plate of 0.2-0.3g / cm3, and then dissolves the thermosetting phe...

Embodiment 1

[0045] Use 50-mesh flake graphite, use concentrated sulfuric acid and nitric acid to carry out oxidation intercalation reaction according to a certain ratio, wash and dry to obtain expandable graphite, expandable graphite expands at 850°C, and the expansion ratio is 200 times, and the expanded graphite is pressed into density It is 0.2g / cm3 plate, and the thickness of the plate is 3mm. According to the size of the dipping tank, the plate specification is designed to be 500x500mm.

[0046] Use paraffin as the energy storage phase change material, the phase change temperature is 58°C, and the phase change heat is 190KJ / kg. Melt the phase change paraffin in the container, and use the vacuum impregnation box to enter the low-density expanded graphite In the vacuum box of the plate, the vacuum box is kept at 65°C, and the vacuum degree of the vacuum box equipped with the graphite plate is kept at -0.095MPa before the paraffin is inhaled.

[0047] After the graphite plate is impreg...

Embodiment 2

[0059] The manufacturing method of the expanded graphite paraffin composite board is the same as in Example 1.

[0060] Manufacture 0.2g / cm expanded graphite foam plate according to embodiment 1, then thermosetting phenolic resin is dissolved into the solution that concentration is 20% with dehydrated alcohol, adopts the method for vacuum impregnation, impregnates thermosetting phenolic resin in graphite plate, impregnated After the graphite plate is dried, it is pulverized with a plastic pulverizer, and then pulverized into an 80-mesh powder with a stirring mill, and hot-pressed into a 1.7g / cm 3 Graphite plates with a density of 2mm and a thickness of 0.18mm are used to process high-strength flexible graphite plates into parts with mounting holes, and the size of the parts is 50x50mm. The graphite plate is cured at a temperature of 175°C to obtain a high-strength flexible graphite plate. The thermal conductivity of the high-strength flexible graphite plate in the plate direc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com