Method for preparing Nb/NbCr2-based high-temperature alloy surface anti-oxidation composite coating

A technology of superalloy and composite coating, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of room temperature plasticity and toughness decline, anti-oxidation performance, and insufficient bonding force between coating and substrate and other problems, to achieve the effect of improving high temperature oxidation resistance and good peeling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention is realized like this, it is characterized in that method step is:

[0027] (1) Preparation of Si-Al coating

[0028] ①The penetrating agent consists of 8Si, 6Al, 1NaF, 65Al in mass fraction wt.%. 2 o 3 composition;

[0029] ② After the penetrating agent is mixed, the rotation speed is 300r / m, and it is refined by ball milling for 2 hours;

[0030] ③Then bury the infiltrated sample in a corundum crucible filled with an infiltrating agent, cover the lid, seal it with a high-temperature adhesive, and dry it at 100°C for 2 hours;

[0031] ④Put it in a high-temperature electric furnace and keep it at 800°C for 2 hours. The heating rate is about 16°C / min. After the heat preservation is over, the sample is cooled to room temperature with the furnace, and the surface is taken out and cleaned to obtain a Si-Al co-infiltration sample;

[0032] (2) Preparation of Al(OH) by Sol-gel method 3 sol

[0033] ① Prepare 0.1mol / L Al(NO 3 ) 3 solution;

[003...

Embodiment 2

[0041] The present invention is realized like this, it is characterized in that method step is:

[0042] (1) Preparation of Si-Al coating

[0043] ① The penetrating agent consists of 20Si, 15Al, NaF, 85Al in mass fraction wt.%. 2 o 3 composition;

[0044] ② After the penetrating agent is mixed, the rotation speed is 500r / m, and it is refined by ball milling for 10 hours;

[0045] ③Then bury the infiltrated sample in a corundum crucible filled with an infiltrating agent, cover the lid, seal it with a high-temperature adhesive, and dry it at 100°C for 2 hours;

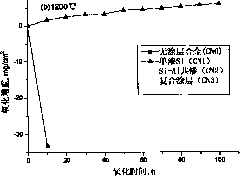

[0046] ④Put it in a high-temperature electric furnace and keep it at 1200°C for 2 hours. The heating rate is about 16°C / min. After the heat preservation is over, the sample is cooled to room temperature with the furnace, and the surface is taken out and cleaned to obtain a Si-Al co-infiltration sample;

[0047] (2) Preparation of Al(OH) by Sol-gel method 3 sol

[0048] ① Prepare 0.22mol / L Al(NO 3 ) 3 solution;

...

Embodiment 3

[0056] The present invention is realized like this, it is characterized in that method step is:

[0057] (1) Preparation of Si-Al coating

[0058] ① The penetrating agent consists of 12Si, 10Al, 5NaF, 70Al in mass fraction wt.%. 2 o 3 composition;

[0059] ② After the penetrating agent is mixed, the rotation speed is 400r / m, and it is refined by ball milling for 5 hours;

[0060] ③Then bury the infiltrated sample in a corundum crucible filled with an infiltrating agent, cover the lid, seal it with a high-temperature adhesive, and dry it at 100°C for 2 hours;

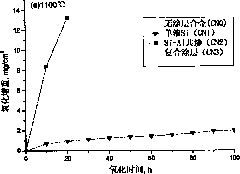

[0061] ④Put it in a high-temperature electric furnace at 1100°C for 2 hours, and the heating rate is about 16°C / min. After the heat preservation is over, the sample is cooled to room temperature with the furnace, and the surface is taken out and cleaned to obtain a Si-Al co-infiltration sample;

[0062] (2) Preparation of Al(OH) by Sol-gel method 3 sol

[0063] ① Prepare 0.15mol / L Al(NO 3 ) 3 solution;

[0064] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com