Preparation method of polysilicate diboride flocculant

A technology of polysilicate and flocculant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of short storage period, achieve the effect of improving stability, excellent oil removal performance, and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

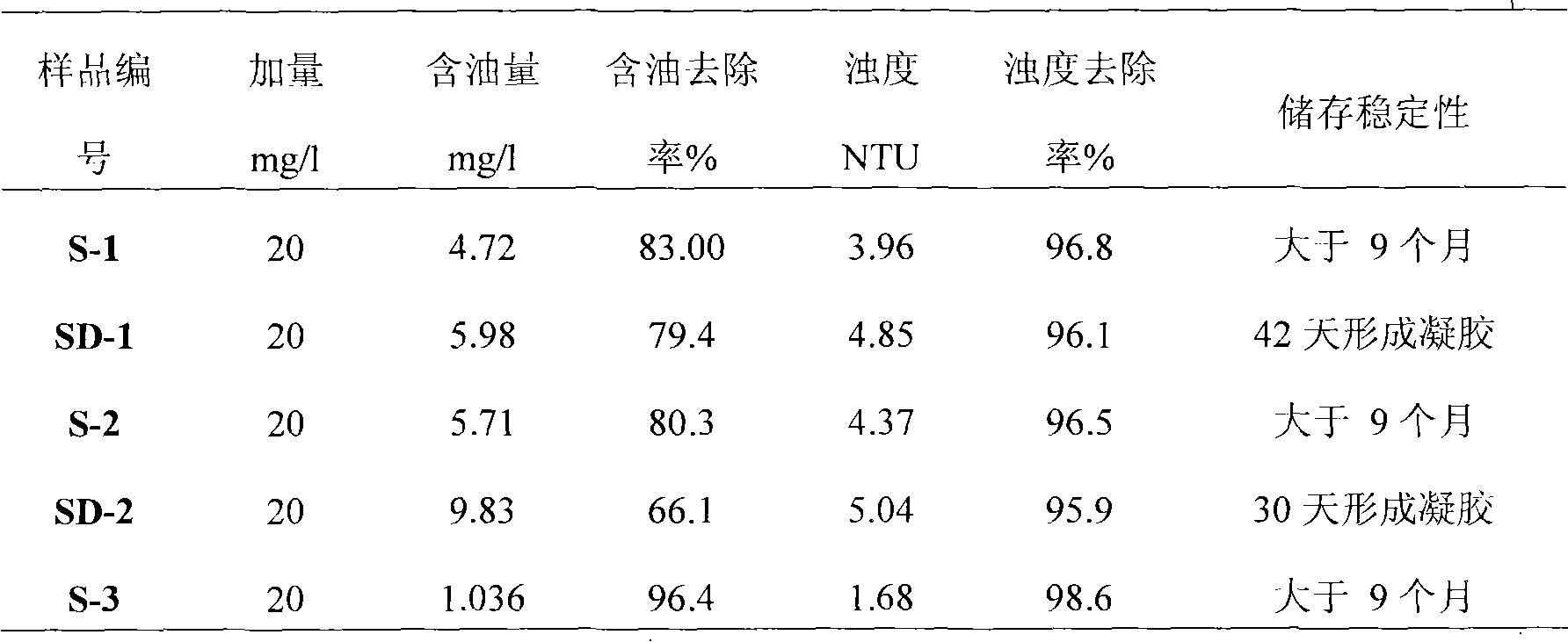

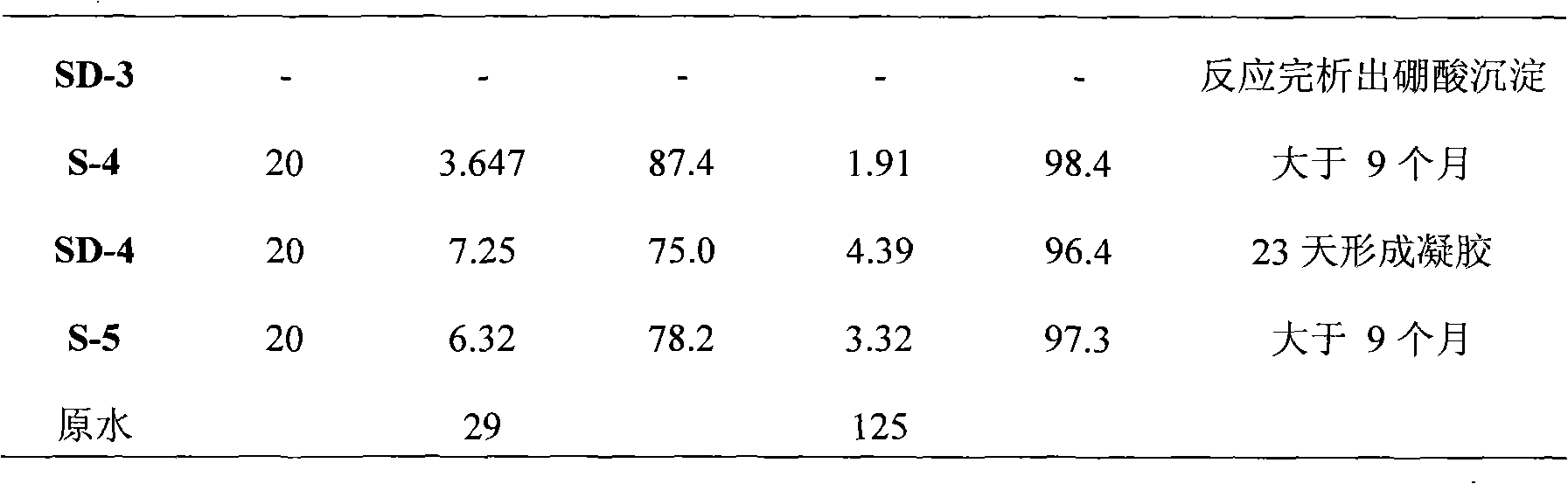

Examples

Embodiment 1

[0021] Prepare 160g of sodium silicate solution with a concentration of 15%, adjust its pH value to 4 at room temperature with sulfuric acid, age for 18 hours, and prepare 53.8g of aluminum sulfate solution with a concentration of 20%, and a zinc chloride solution with a concentration of 25%. A mixture of 21.5 g and 5.3 g of boric acid-isooctyl and boric acid-diisooctyl was added to the aged sample, stirred at room temperature for 4 hours, and left to stand for 24 hours to obtain product S-1.

Embodiment 2

[0025] Prepare 200g of potassium silicate solution with a concentration of 12%, adjust its pH value to 3 with phosphoric acid at 30°C, and after aging for 20 hours, mix 107g of aluminum sulfate solution with a concentration of 10% and zinc chloride with a concentration of 5%. 106 g of the solution and 12.5 g of a mixture of boric acid-isooctyl and boric acid-diisooctyl were added to the aged sample, stirred at room temperature for 3 hours, and left to stand for 10 hours to obtain product S-2.

Embodiment 3

[0029] Prepare 135 g of sodium silicate solution with a concentration of 35%, adjust its pH value to 2 with hydrochloric acid at 30° C., and age for 10 hours. Concentration is that 10% aluminum chloride solution 107g, the mixture that concentration is 15% zinc chloride solution 100g and 8g ethyl borate and boric acid-diethyl ester are added respectively in the aging sample, stirred at room temperature for 6 hours, After standing still for 16 hours, product S-3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com