Novel drying oven and drying method thereof

A drying method and drying oven technology, which is applied in the direction of drying solid materials, drying chambers/containers, local agitation dryers, etc., can solve the problems of water vapor mass transfer and heat transfer limitations, changes in the properties of materials to be dried, and incomplete drying of materials, etc. , to achieve the effects of not being easy to stay and condense, improving flow and distribution, and reducing the temperature of the drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

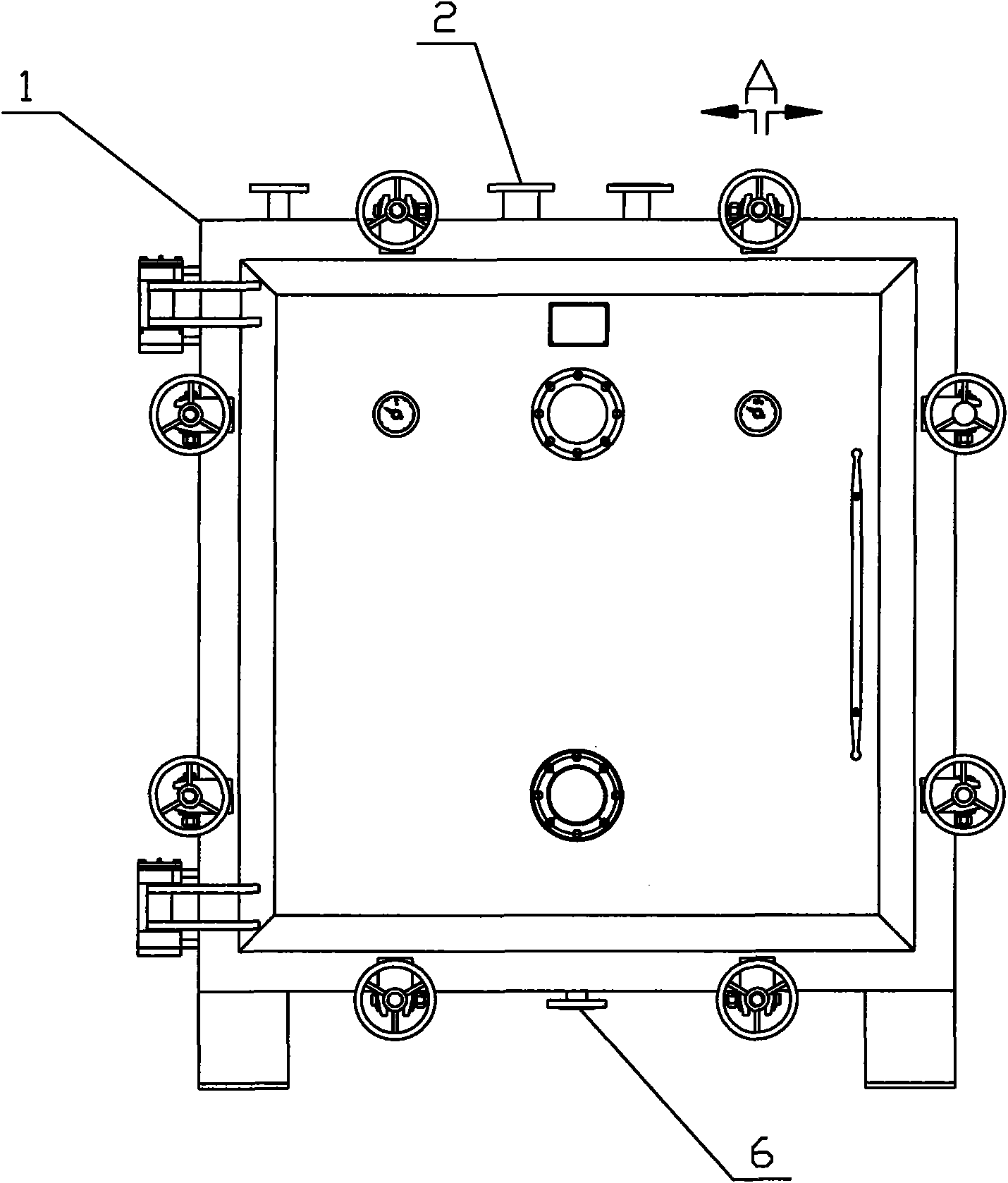

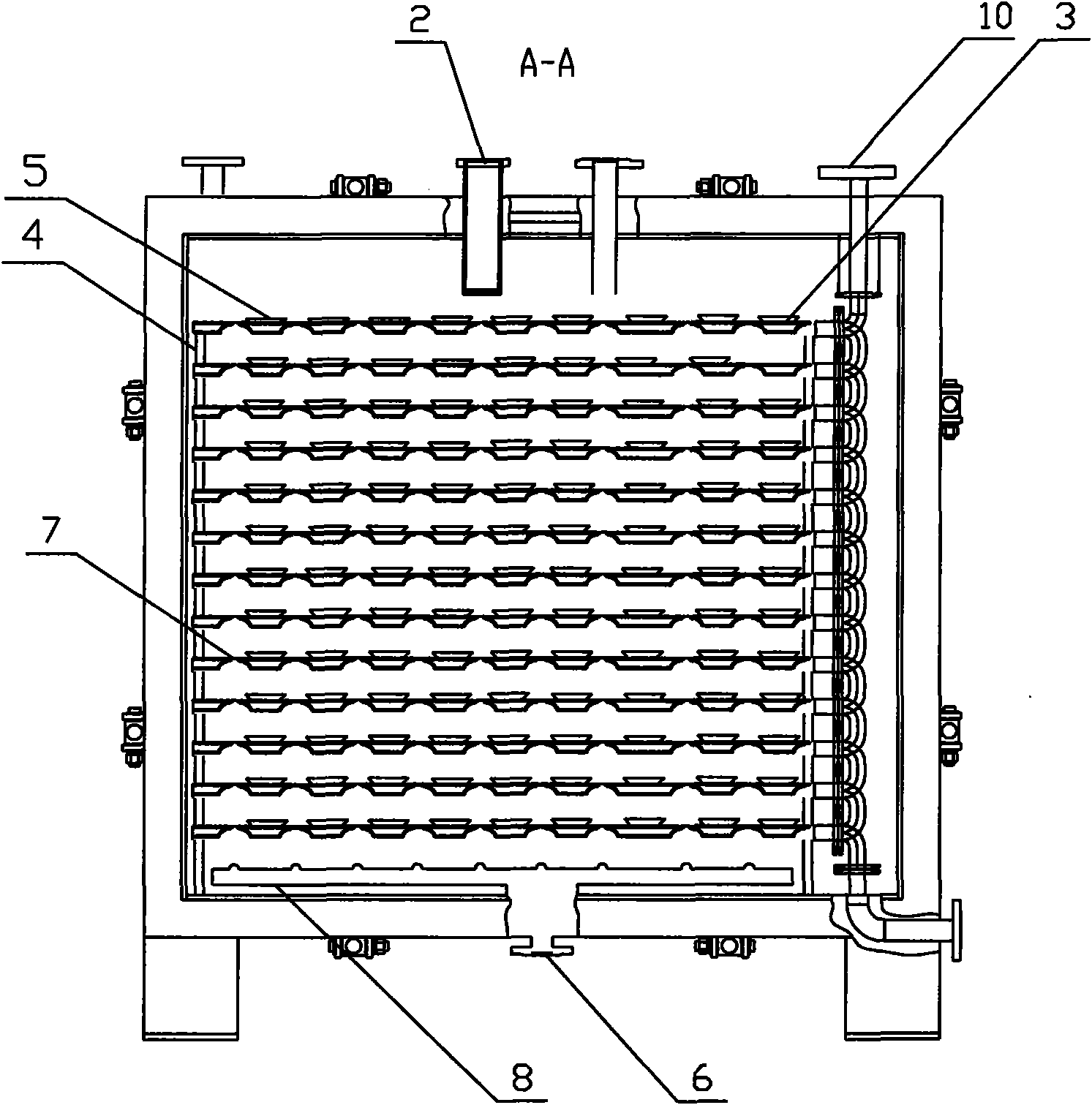

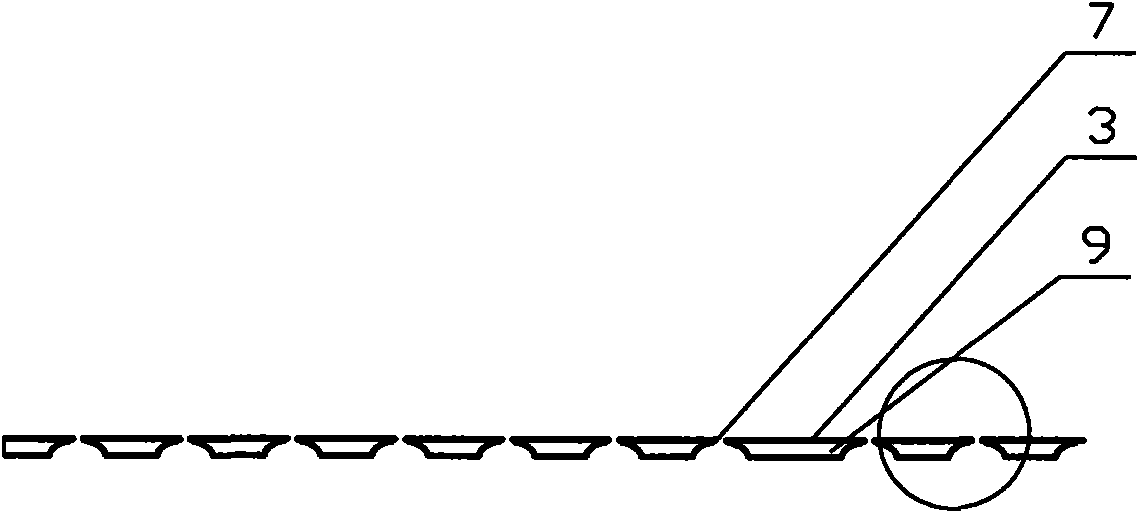

[0033] A new type of drying oven, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes an oven shell 1, an air outlet 2, a flat panel 3, and a bracket 4 for placing the flat panel 3. The flat panel 3 is provided with a tray 5 for holding dried objects. The flat panel 3 is a breathable flat panel, and the drying box Have gas inlet 6 on it. The air-permeable flat panel is a flat panel with a heating device 9 attached.

[0034] In the above structure, there is a gas inlet pipe at the gas inlet 6 at the bottom of the drying box, and 72 equidistant circular air holes 11 with a diameter of 10 mm are evenly distributed on the gas-permeable flat plate with a length of 1320 mm and a width of 1000 mm. One end of the gas inlet pipe close to the air-permeable flat plate is connected with a gas distribution pipe 8, and the gas distribution pipe 8 is distributed with several small holes corresponding to the air holes on the air-permeable flat plate. ...

Embodiment 2

[0041] A new type of drying oven, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes an oven shell 1, an air outlet 2, a flat panel 3, and a bracket 4 for placing the flat panel 3. The flat panel 3 is provided with a tray 5 for holding dried objects. The flat panel 3 is a breathable flat panel, and the drying box There is a gas inlet 6 on the top, and several air-permeable structures 7 are distributed on the air-permeable flat plate. The air-permeable structures 7 can be air holes, the air holes are circular, and the aperture of the air holes is 0.01mm. The air-permeable flat plate is Flat plate without additional heating means 9. One end of the gas inlet pipe close to the air-permeable flat plate is connected with a gas distribution pipe 8, and the gas distribution pipe 8 is distributed with several small holes corresponding to the air holes on the air-permeable flat plate. The oven shell is provided with a safety valve and spare port....

Embodiment 3

[0048] A new type of drying oven, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes an oven shell 1, an air outlet 2, a flat panel 3, and a bracket 4 for placing the flat panel 3. The flat panel 3 is provided with a tray 5 for holding dried objects. The flat panel 3 is a breathable flat panel, and the drying box There is a gas inlet 6 on it, and at least one breathable structure 7 is distributed on the breathable flat plate. The breathable structure 7 is a breathable seam.

[0049] A kind of drying method of novel drying box, the steps are as follows:

[0050] The first step: open the drying box, put the substance to be heated in the tray 5 on the air-permeable flat plate in the drying box;

[0051] Step 2: Heat the air-permeable flat panel directly with the power supply, and then use the air-permeable flat panel to heat the dried objects in the tray 5 through heat conduction;

[0052] The third step: continue to dry, the ventilated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com