Spin-riveting-type spring brake chamber, brake system adopting same and vehicle

A technology of spring brake air chamber and brake air chamber, which is applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of large dimensional error, weak connection, small contact surface, etc., and achieve surface quality Good, reduce the exposed length and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

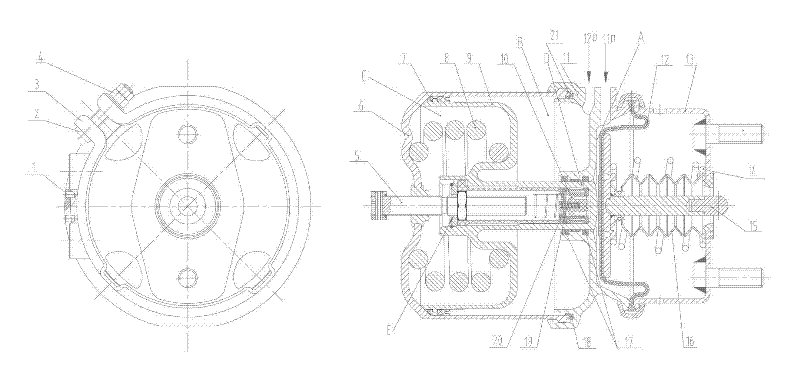

[0027] like figure 1 In the prior art shown, the cylinder body 1 stamped by steel plate and the connection between the middle housing 2 and the cylinder body 1 of the disc spring brake air chamber are all formed by stamping steel plates. The disadvantage is that the cylinder body is deformed after stamping, resulting in The size error is large, the contact surface between the cylinder block and the middle shell is small, the connection is not firm, and it will fall off and disintegrate under the influence of vibration during driving, causing safety accidents.

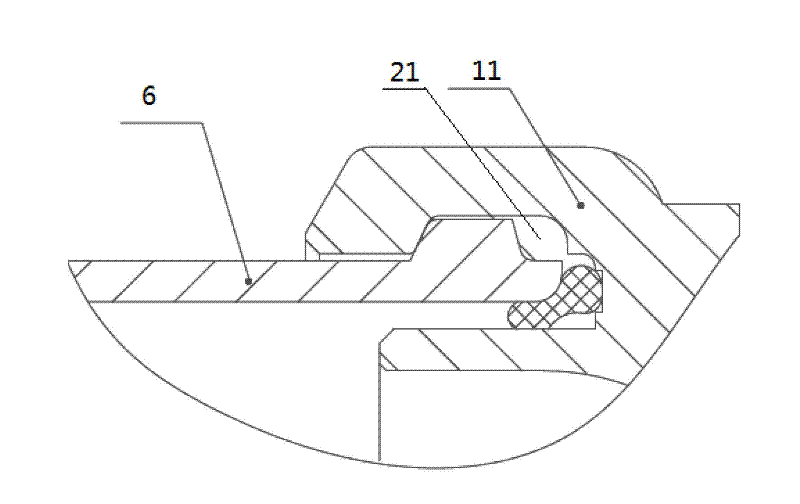

[0028] like figure 2 As shown, the spin riveting spring brake air chamber structure of the present invention is mainly composed of cylindrical pin 1, clamp bolt 2, clamp 3, nut 4, tie rod bolt 5, cylinder body 6, Y-shaped sealing ring 7, brake spring 8 , energy storage piston 9, one-way valve 10, middle housing 11, diaphragm 12, front end cover 13, return spring 14, push plate assembly 15, dust cover 16, O-ring 17, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com