Method for preparing potassium-sodiumniobate lead-free piezoelectric thick film

A potassium sodium niobate, lead-free piezoelectric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of no piezoelectric properties, ferroelectric and piezoelectric Poor performance and other problems, to achieve the effect of not easy to hydrolyze, improve electrical properties, and reduce crystallization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

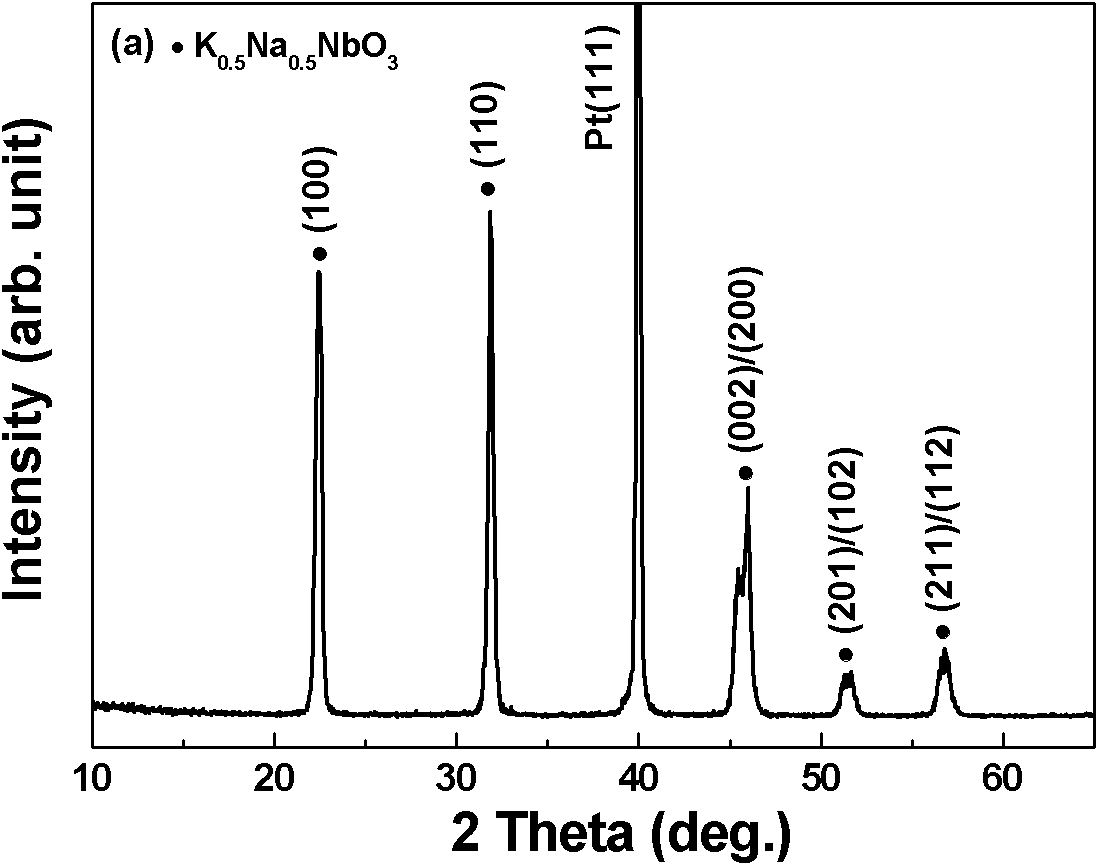

Embodiment 1

[0037] (1) Molar ratio of NbCl 5 : ethanol=1: Weigh anhydrous niobium chloride and absolute ethanol respectively at 1: 10, first niobium chloride is evenly dispersed in the reaction solvent benzene, after stirring for 1 hour, slowly drop into absolute ethanol, and then stir for 1 hour to promote It was fully reacted, and then passed through ammonia gas for 4 hours to remove the excess ion Cl introduced therein - , the resulting white precipitate NH 4 Cl suction filtration, the obtained filtrate is washed with benzene, and the benzene and excess absolute ethanol are removed by normal pressure distillation to obtain pure stable niobium ethoxide.

[0038] (2) According to K 0.5 Na 0.5 NbO 3 The stoichiometric ratio, additionally taking into account the alkali metal ion K during heat treatment + and Na + The volatilization of the formula is calculated by 10% excess of potassium and sodium, that is, according to the molar ratio formula K:Na:Nb=0.55:0.55:1.00, anhydrous sodium...

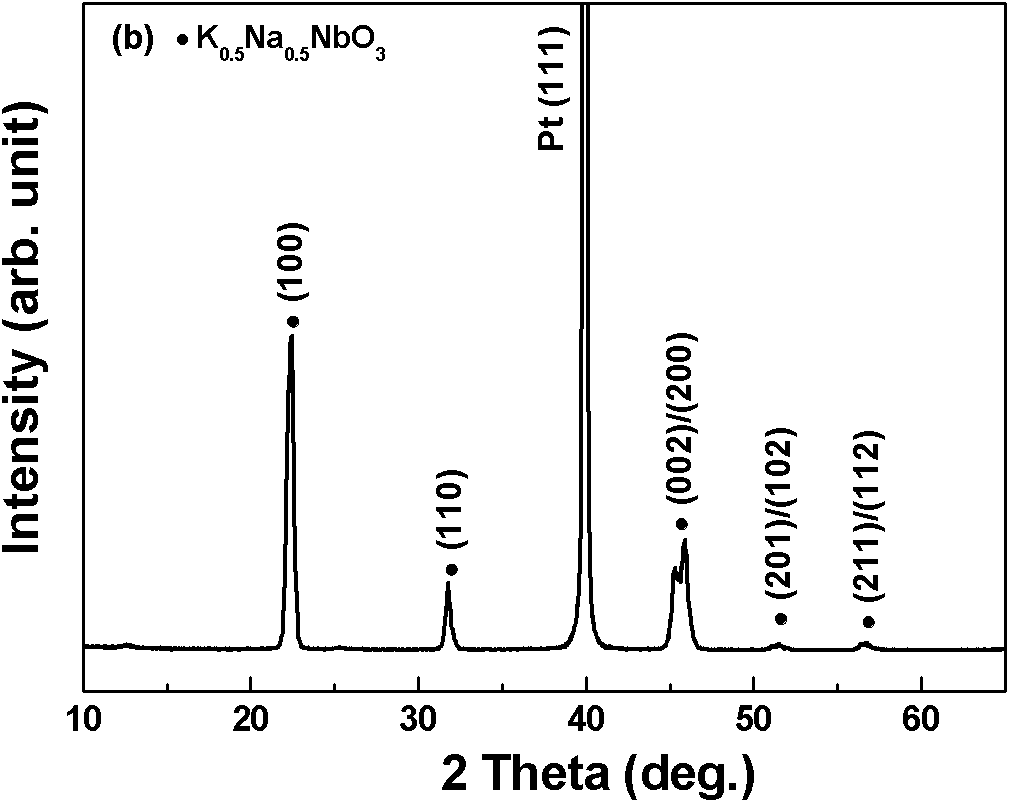

Embodiment 2

[0042] (1) Molar ratio of NbCl 5 : ethanol=1: 15 Weigh anhydrous niobium chloride and absolute ethanol respectively, first niobium chloride is evenly dispersed in the reaction solvent benzene, after stirring for 1 hour, slowly drop into absolute ethanol, and then stir for 1 hour to promote It was fully reacted, and then passed through ammonia gas for 4 hours to remove the excess ion Cl introduced therein - , the resulting white precipitate NH 4 Cl suction filtration, the obtained filtrate is washed with benzene, and the benzene and excess absolute ethanol are removed by normal pressure distillation to obtain pure stable niobium ethoxide.

[0043] (2) According to K 0.5 Na 0.5 NbO 3 The stoichiometric ratio, additionally taking into account the alkali metal ion K during heat treatment + and Na + The volatilization of the formula is calculated by 5% excess of potassium and sodium, that is, according to the molar ratio formula K:Na:Nb=0.525:0.525:1.00, anhydrous sodium acet...

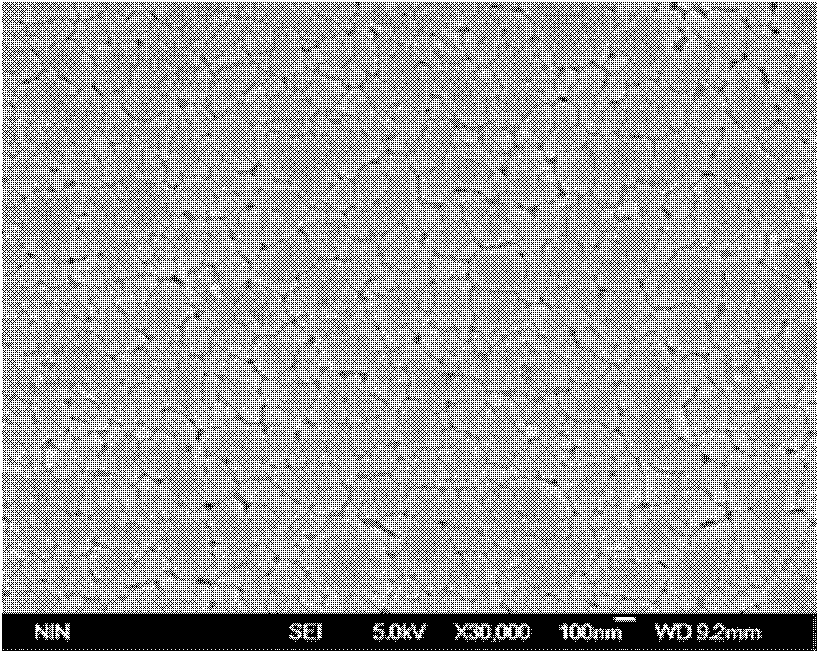

Embodiment 3

[0048] (1) Molar ratio of NbCl 5 : ethanol=1: 20 Weigh anhydrous niobium chloride and absolute ethanol respectively, first niobium chloride is evenly dispersed in the reaction solvent benzene, after stirring for 1 hour, slowly drop into absolute ethanol, and then stir for 1 hour to promote It was fully reacted, and then passed through ammonia gas for 4 hours to remove the excess ion Cl introduced therein - , the resulting white precipitate NH 4 Cl suction filtration, the obtained filtrate is washed with benzene, and the benzene and excess absolute ethanol are removed by normal pressure distillation to obtain pure stable niobium ethoxide.

[0049] (2) According to K 0.5 Na 0.5 NbO 3 The stoichiometric ratio, and taking into account the alkali metal ion K during heat treatment + and Na + The volatilization of the formula is calculated by 15% excess of potassium and sodium, that is, according to the molar ratio formula K:Na:Nb=0.575:0.575:1.00, anhydrous sodium acetate, anh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com