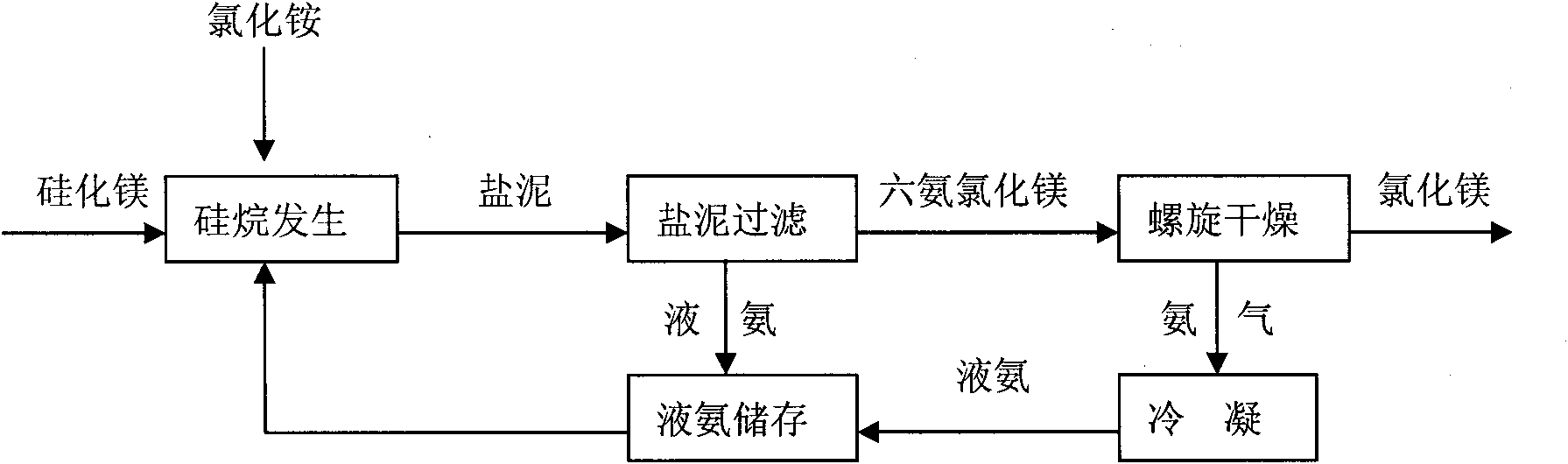

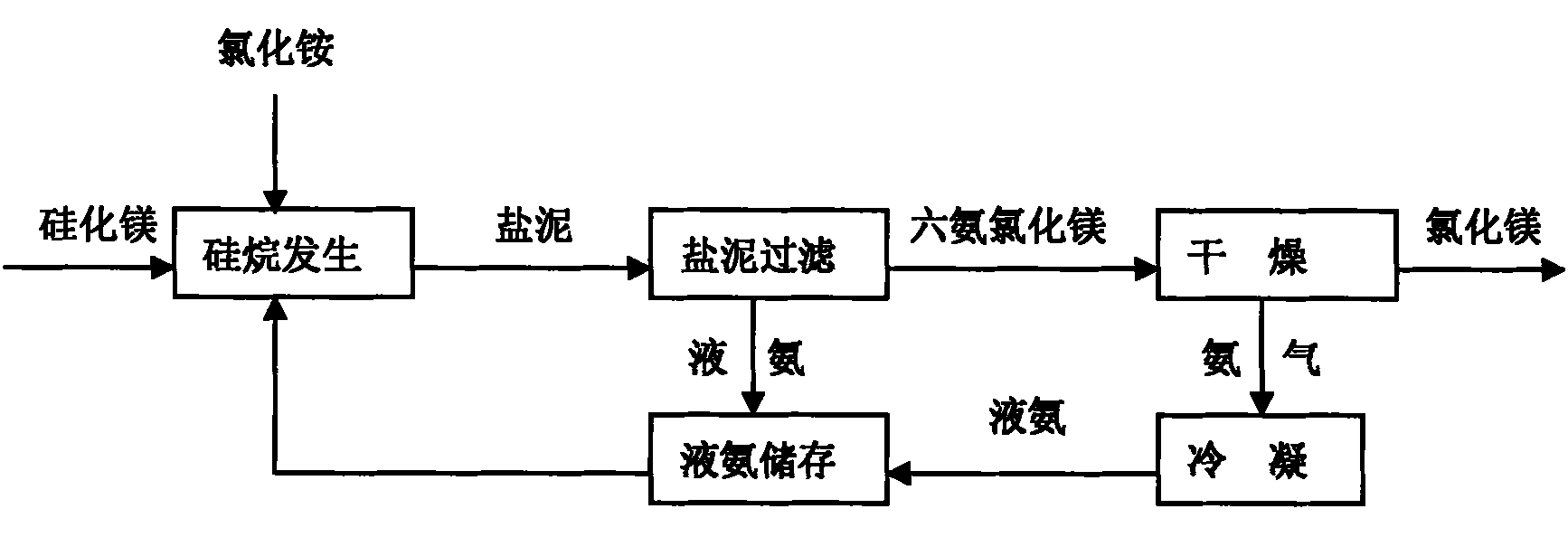

Method and device for separating magnesium chloride hexammoniate during silane production by the magnesium silicide method

A technology of hexaammoniated magnesium chloride and magnesium silicide, which is applied in the field of separation and recovery of hexaammoniated magnesium chloride and liquid ammonia, can solve the problems of insufficient ammonia recovery, small production scale, and environmental pollution, and achieve high efficiency, fast speed, solid liquid retention less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

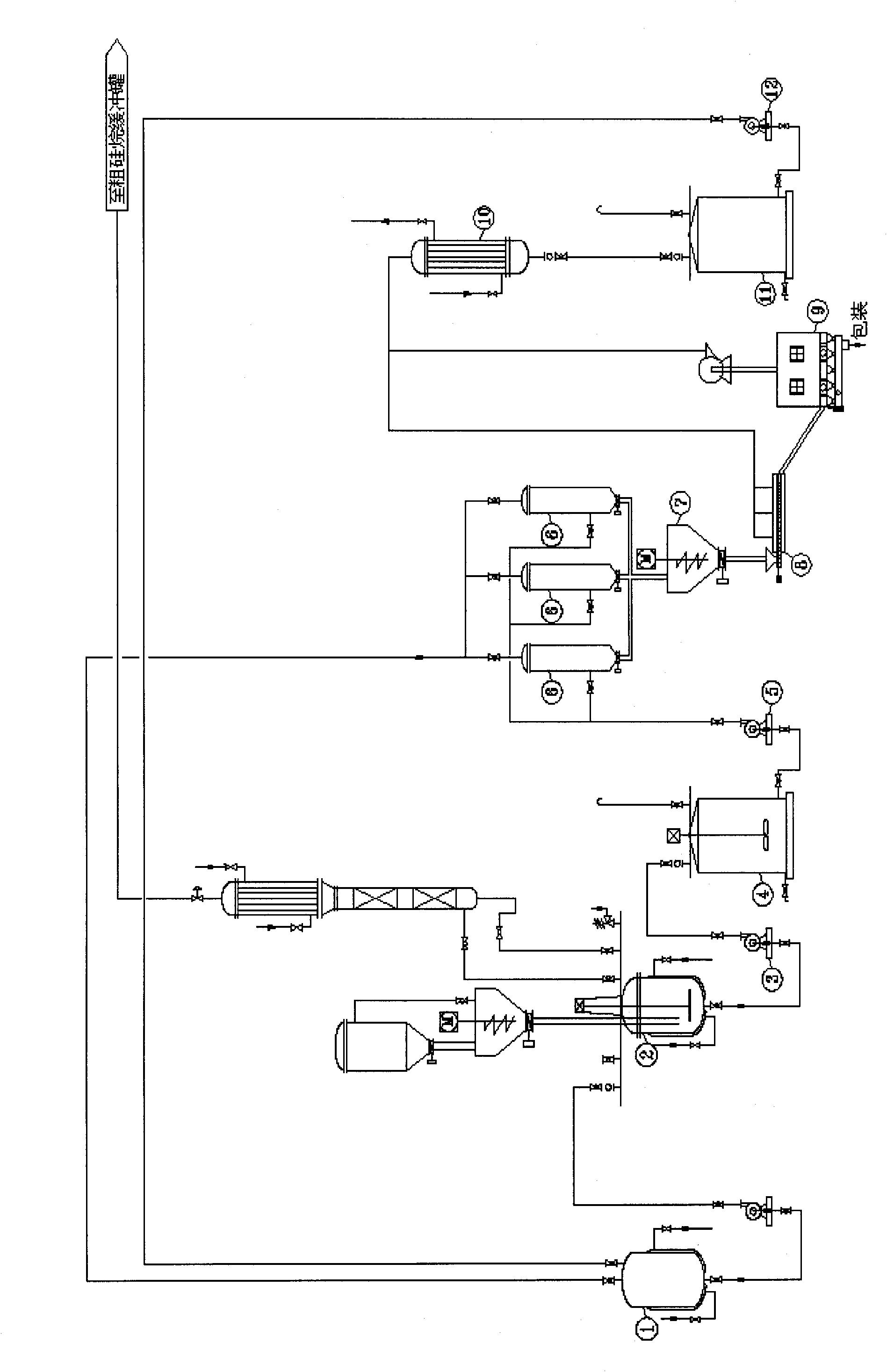

[0039] The separation and recovery device of hexaammoniated magnesium chloride and liquid ammonia in the process of producing silane by the magnesium silicide method of the present invention comprises a salt mud extraction pump 3, a salt mud middle tank 4, a salt mud filtration pump 5, a filter 6, and a salt mud feeder 7 , screw dryer 8, condenser 10, liquid ammonia storage tank 1, liquid ammonia recovery tank 11, liquid ammonia recovery pump 12 and magnesium chloride packaging machine 9, the outlet of salt mud extraction pump 3 is connected with the top of salt mud middle tank 4, The salt mud middle tank 4 is equipped with a stirring device, the lower outlet of the salt mud middle tank 4 is connected with the salt mud filter pump 5, and the outlet of the salt mud filter pump 5 is connected with the salt mud filter 6, and the filter 6 is a clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com