Low-metal ceramic-based drum-type brake pad and preparation method thereof

A technology for brake pads and low metal, applied in the field of low metal drum brake pads and the preparation thereof, can solve the problems of unsatisfactory braking performance and braking comfort performance, easy rusting of brake pads, excessive heat conduction, etc. The effect of braking smoothness, prolonging service life and reducing noise

Inactive Publication Date: 2010-08-25

HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing brake pads are mainly semi-metallic brake pads, the metal content of which exceeds 40%, and the heat conduction is too large, so the braking performance and braking comfort performance under high-speed conditions are not ideal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

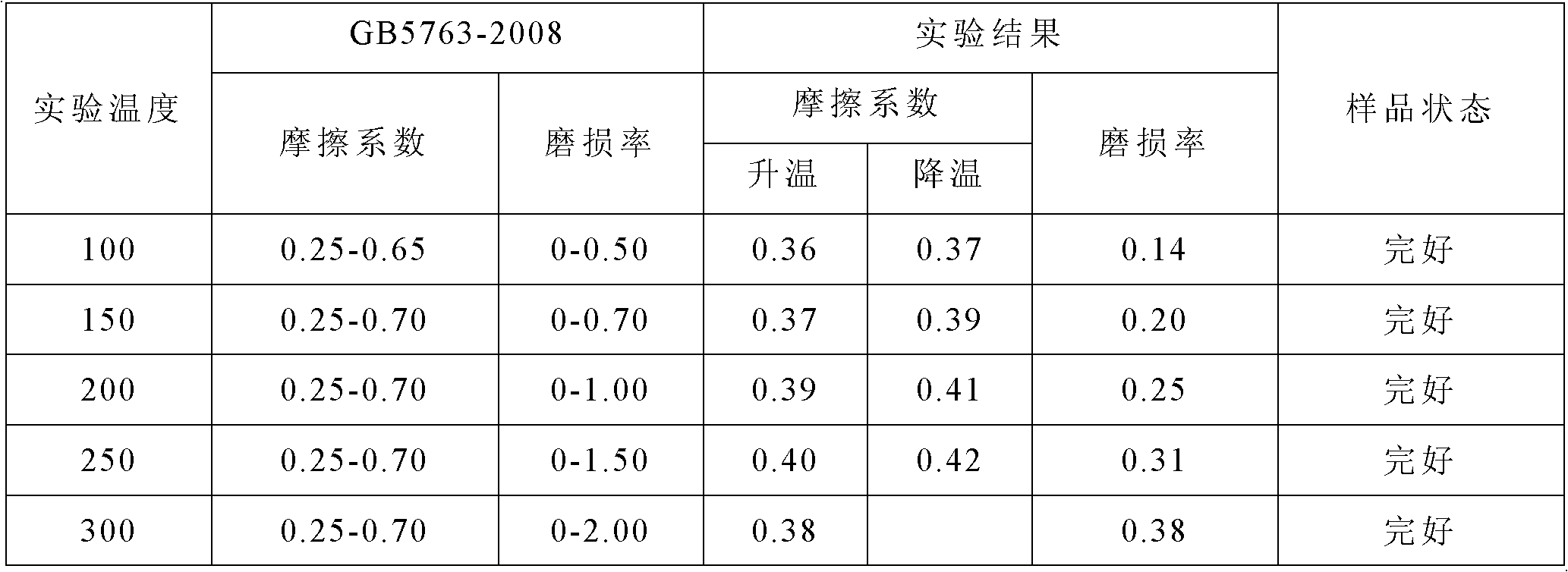

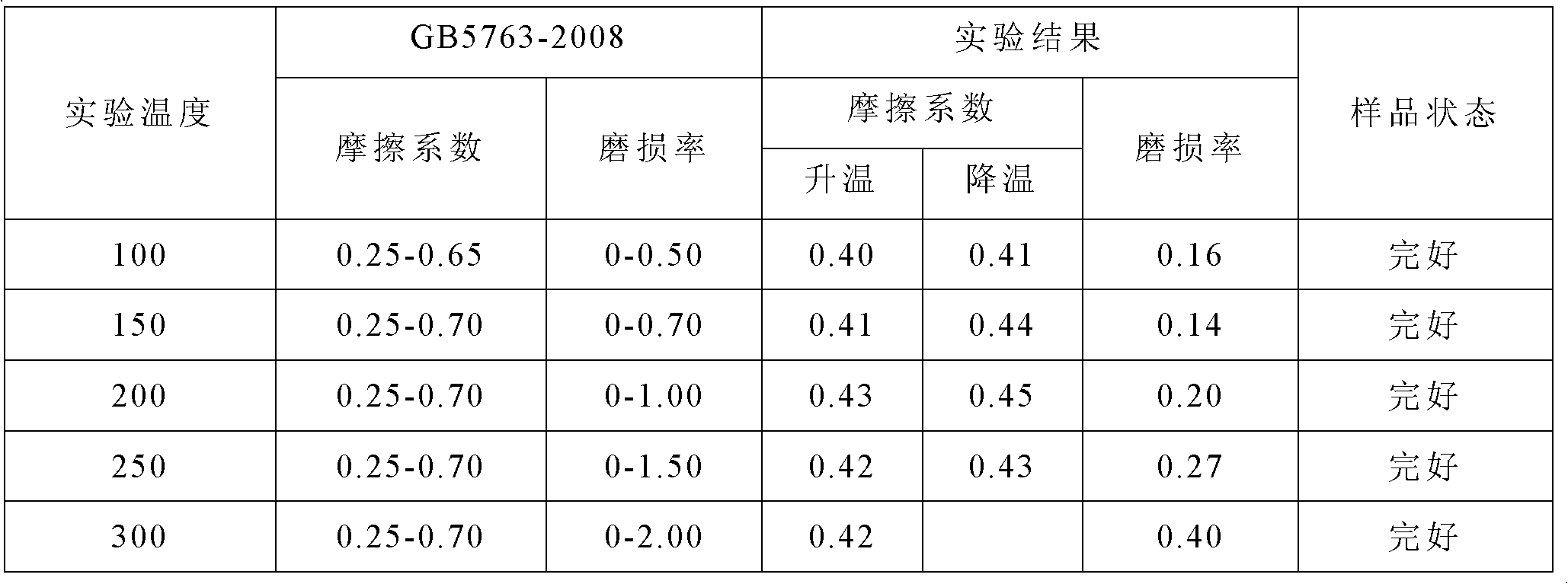

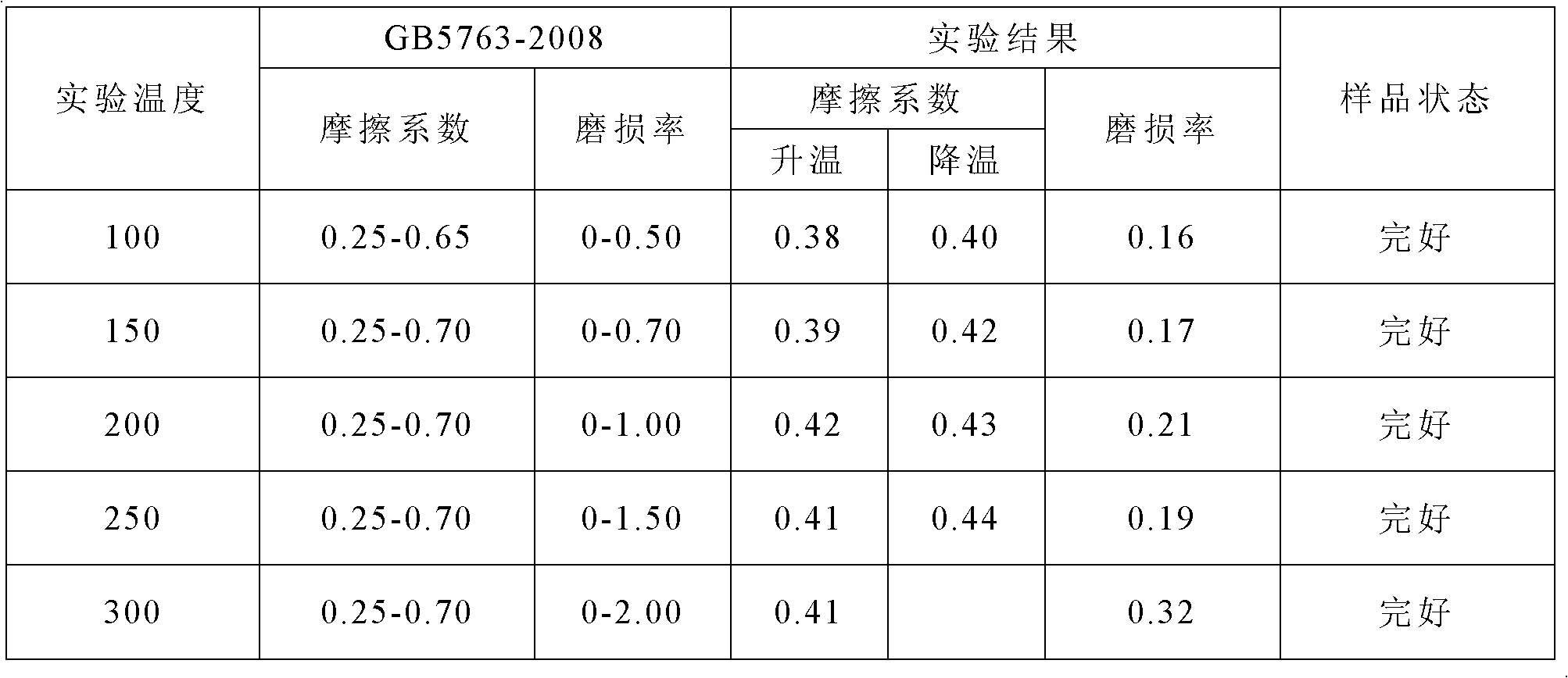

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a low-metal ceramic-based drum-type brake pad and a preparation method thereof. The low-metal ceramic-based drum-type brake pad comprises the following raw materials by weight percent: 20 to 30 of ceramic adhesive, 10 to 20 of steel fibre, 15 to 30 of composite fibre, 0 to 5 of calcium carbonate crystal whisker, 2 to 5 of glass fibre, 0 to 5 of artificial graphite, 5 to 10 of crystalline flake graphite, 0 to 5 of chromium chromite, 2 to 5 of friction powder and 0 to 15 of composite filler. The preparation method comprises the steps of mixing, cold pressing, hot pressing, heat treatment, machining and ceramic treatment. The brake pad prepared by the invention has the characteristics of high-temperature resistance, high-pressure resistance, impact resistance and the like. Compared with a traditional product, the service life is enhanced by more than 2 times.

Description

technical field The invention belongs to the technical field of friction materials, in particular to a low-metal drum brake pad and a preparation method thereof. Background technique At present, the main raw materials of brake pads are adhesives, reinforcing fibers, lubricants and necessary regulators. The preparation process is material mixing-pressing-heat treatment-machining-painting-installation accessories-packaging. With the rapid development of the automobile industry, the speed of passenger cars is getting higher and higher, which also requires that the brake pads not only have good braking performance, but also have good heat resistance and good braking comfort. Existing brake pads are mainly semi-metallic brake pads, the metal content of which exceeds 40%, and the heat conduction is too large, so the braking performance and braking comfort performance under high-speed conditions are not ideal. In addition, due to the high metal content, there is a lot of noise wh...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16D69/02C04B35/76C04B35/80C04B35/81C04B35/82

Inventor 刘伯威贺云果唐兵

Owner HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com