Method for preparing surface molded shell cast by high-temperature titanium alloy melting mold

A high-temperature titanium alloy and investment casting technology, applied in casting and molding equipment and other directions, can solve the problems of easily polluted environment and high cost of mold shell, and achieve the effect of excellent performance and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

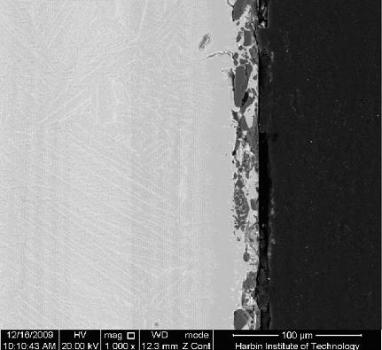

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment 1: The method for preparing the surface layer shell for high-temperature titanium alloy investment casting in this embodiment is carried out according to the following steps: 1. Preparation of mixed binder: SiO 2 The hydrolyzed solution obtained after colloid hydrolysis, the hydrolyzed solution is mixed with the zirconium acetate binder after standing for 20~28 hours, the mass ratio of the hydrolyzed solution to the zirconium acetate binder is 1:1~1.5, and then the mixture is added into the mixture The total mass of 3%~10% polyvinyl butyral is stirred and mixed for 10~20 minutes to obtain the mixed binder; 2. Preparation of the surface layer slurry: add to each kilogram of the mixed binder prepared in step 1 Add 0.5~1ml of wetting agent and 0.8~1.2ml of defoamer, and then add 2~4kg of 325-mesh refractory powder and stir and mix for 10~24 hours to obtain the surface layer slurry; Dip the angle into the slurry until the surface slurry of the coated wax...

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in step one, SiO 2 After the colloid is hydrolyzed, let it stand for 22-26 hours. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one is: in step one, SiO 2 After the colloid is hydrolyzed, let it stand for 24 hours. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com