Synthesis method of N doped hollow TiO2 microspheres

A synthesis method and technology of microspheres, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

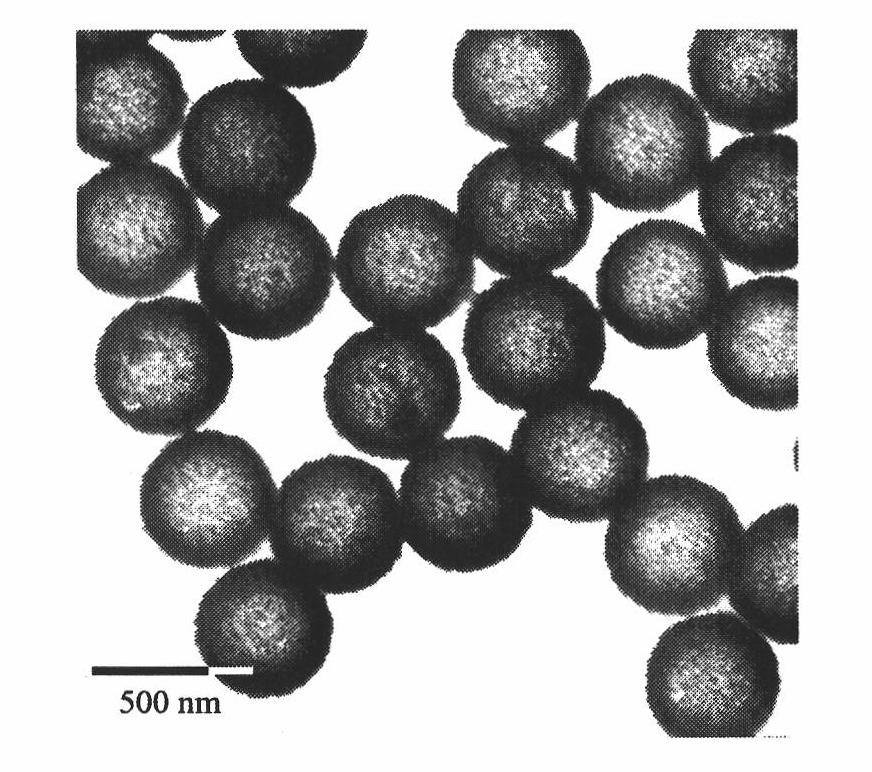

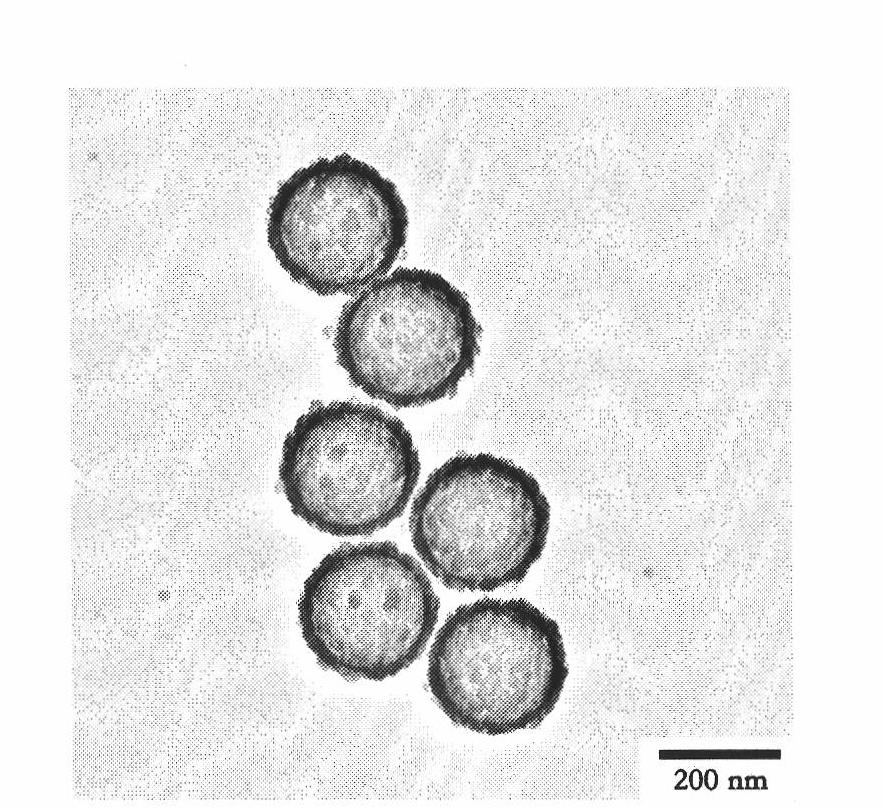

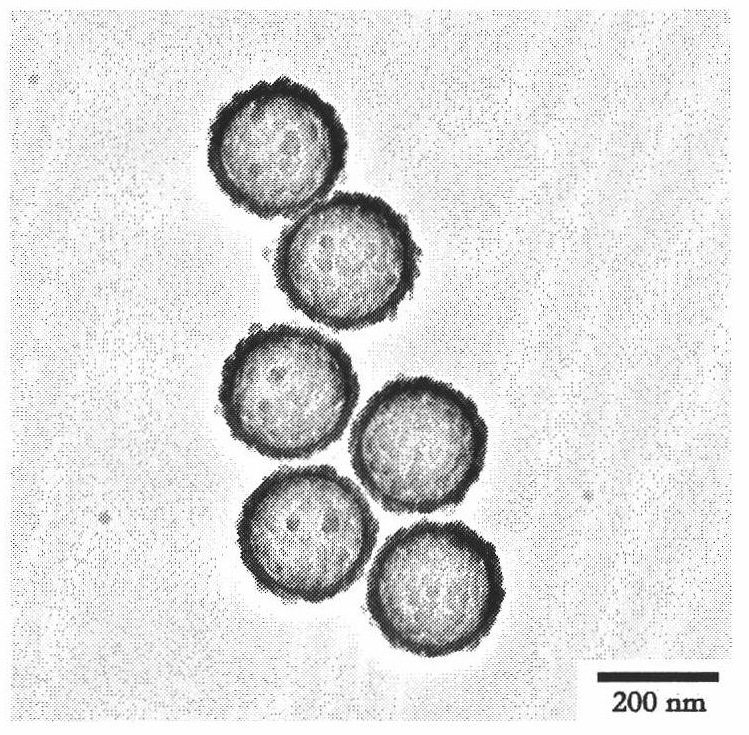

Image

Examples

Embodiment 1

[0017] A kind of N-doped hollow TiO according to the present invention 2 The synthetic method of microsphere, it comprises the following steps:

[0018] 1. Synthesis of PS emulsion: add 10.0g St, 90.0g water into 250mL reaction bottle, N 2 Stir at room temperature for 20 min under protection, then heat to 70° C., add 10.0 g of KPS aqueous solution (1%, mass fraction) and react for 12 h to obtain PS emulsion.

[0019] 2. Synthesis of PS-TiO 2 Composite microspheres: add 95.0g ethanol, 5.0g ammonia water, 5.0g PS emulsion synthesized in step 1 into a 250mL reaction bottle, add 5.0g TBT, TEA, ethanol mixed solution at 50°C for 2.5h, wherein The weight ratio of TBT, TEA, and ethanol in the mixed solution is 1.0:0.2:1.0; after the addition, continue to stir for 5 hours; centrifuge the reaction product and dry it to obtain PS-TiO 2 Composite microspheres.

[0020] 3. The PS-TiO synthesized in step 2 at 500°C 2 The composite microspheres were calcined for 2 hours, and the PS cor...

Embodiment 2

[0022] Another N-doped hollow TiO according to the present invention 2 The synthetic method of microsphere, it comprises the following steps:

[0023] 1. Synthesis of PS emulsion: add 10.0g St, 90.0g water into 250mL reaction bottle, N 2 Stir at room temperature for 20 min under protection, then heat to 70° C., add 10.0 g of KPS aqueous solution (1%, mass fraction) and react for 12 h to obtain PS emulsion.

[0024] 2. Synthesis of PS-TiO 2 Composite microspheres: add 95.0g ethanol, 2.0g ammonia water, 5.0g PS emulsion synthesized in step 1 into a 250mL reaction bottle, add 2.0g TBT, TEA, and ethanol mixed solution at 50°C for 1.0h, wherein The weight ratio of TBT, TEA, and ethanol in the mixed solution is 1.0:0.1:1.0; after the addition, continue to stir for 5 hours; centrifuge the reaction product and dry it to obtain PS-TiO 2 Composite microspheres, in which PS is the core, TiO 2 for the shell.

[0025] 3. The PS-TiO synthesized in step 2 at 500°C 2 The composite micro...

Embodiment 3

[0027] Another N-doped hollow TiO according to the present invention 2 The synthetic method of microsphere, it comprises the following steps:

[0028] 1. Synthesis of PS emulsion: add 10.0g St, 90.0g water into 250mL reaction bottle, N 2 Stir at room temperature for 20 minutes under protection, then heat to 70 ° C, add 10.0 g of KPS aqueous solution (1%, mass fraction) to react for 12 hours, and obtain PS emulsion;

[0029] 2. Synthesis of PS-TiO 2 Composite microspheres: Add 95.0g ethanol, 8.0g ammonia water, 5.0g PS emulsion synthesized in step 1 into a 250mL reaction bottle, add 8.0g TBT, TEA, ethanol mixed solution at 50°C for coating for 4h, mix The weight ratio of TBT, TEA, and ethanol in the solution is 1.0:0.4:1.0; after the addition, continue to stir for 5 hours; centrifuge the reaction product and dry it to obtain PS-TiO 2 Composite microspheres.

[0030] 3. The PS-TiO synthesized in step 2 at 500°C 2 The composite microspheres were calcined for 2 hours, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com