Elliptical ultrasonic vibration auxiliary cutting device with adjustable track

A technology of ultrasonic vibration and cutting device, applied in feeding device, fluid using vibration, metal processing machine parts, etc., can solve the problem of difficult adjustment of elliptical trajectory, and achieve the effect of reducing tool wear, mature technology, and improving the quality of the machined surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

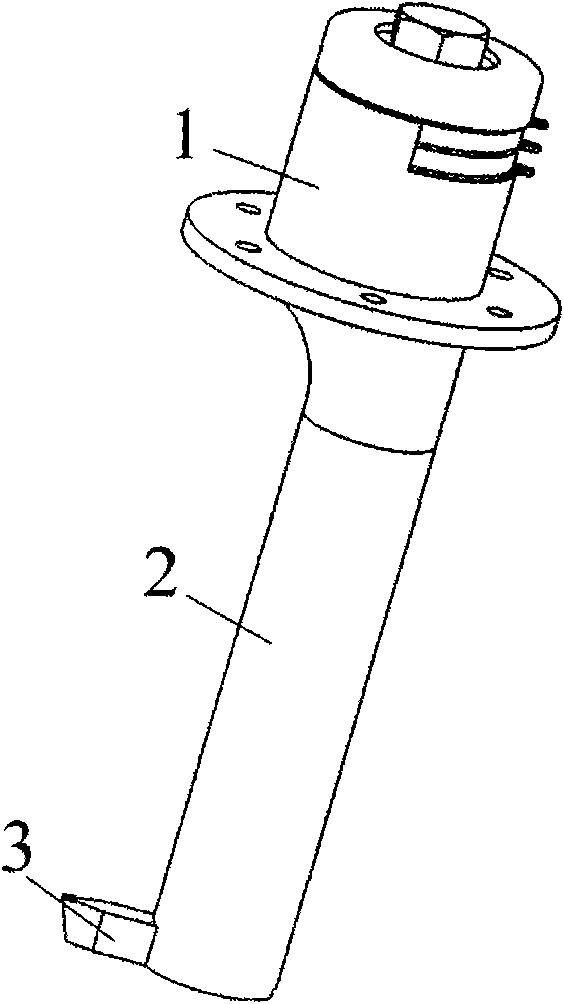

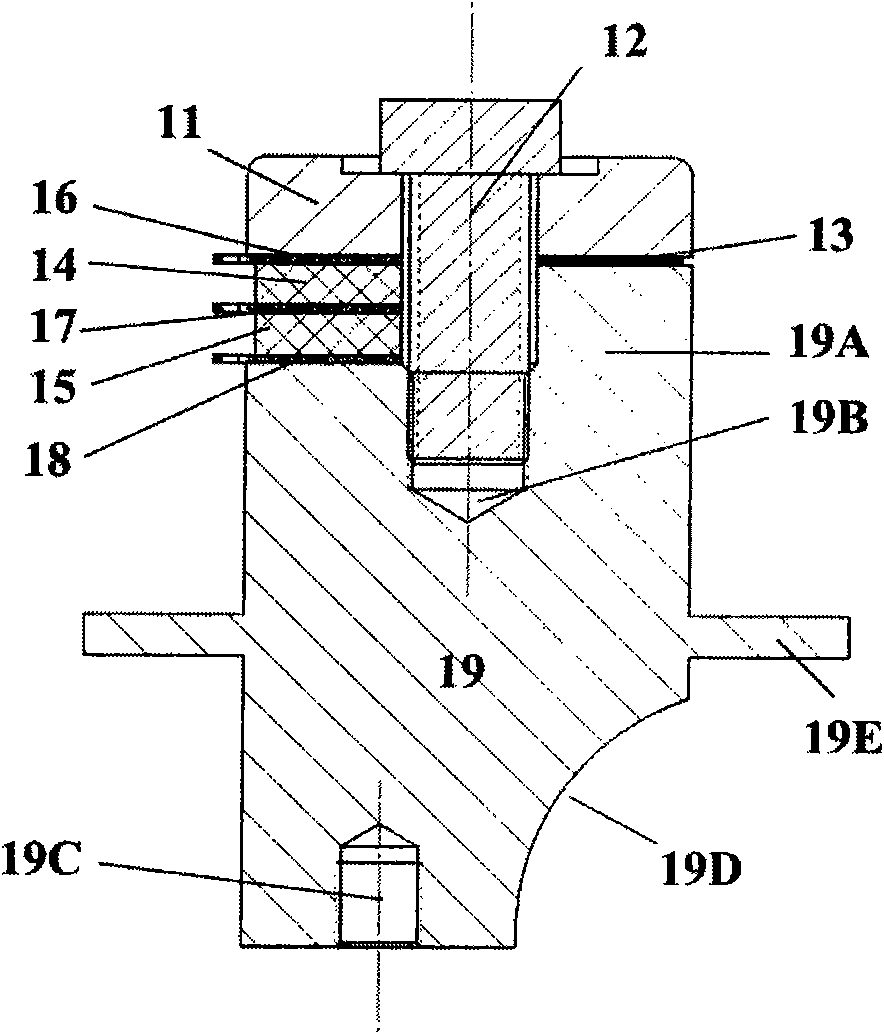

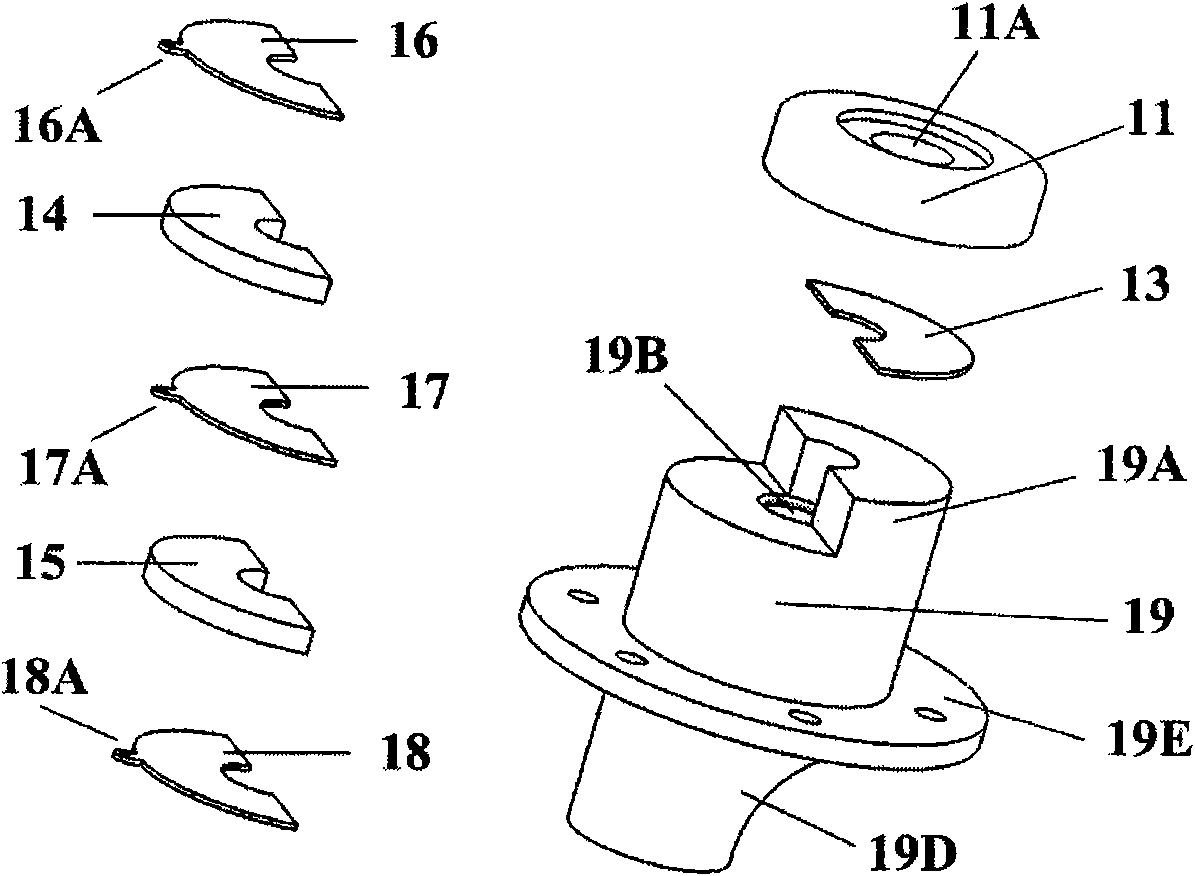

[0021] The prototype structure of the device of the present invention adopts a longitudinal vibration sandwich type piezoelectric transducer, which is a linear vibration device with a resonance type and a single excitation source. The traditional longitudinal vibration sandwich transducer has a symmetrical rotary structure, but in actual operation, it has three forms of longitudinal vibration, torsional vibration and bending vibration. If the transducer has an asymmetrical rotary structure, the bending vibration will be excited to form longitudinal-bending composite vibration and output an elliptical trajectory. Based on this principle, existing studies have proposed elliptical cutting devices, but their asymmetrical rotary structure is mainly realized by tool offset, the asymmetrical feature of the rotary is not obvious and cannot be adjusted, resulting in insufficient bending vibration excitation, and the output elliptical trajectory is relatively large. "flat", and the traj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com