Anticorrosive sealing liquid and method for sealing anodic oxide film containing copper-aluminium alloy by utilizing same

A technology of anodic oxidation film and copper-aluminum alloy, applied in electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of short life of sealing solution, difficult control of hot water, generation of dirt, etc., and achieve stable sealing effect , easy to control, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The first step: sample selection

[0040]The sample is the LY11 alloy treated according to the People's Republic of China Aviation Industry Standard "Sulfuric Acid Anodizing Process for Aluminum and Aluminum Alloys" (HB / Z233-93), with a size of 100mm×50mm×2.5mm;

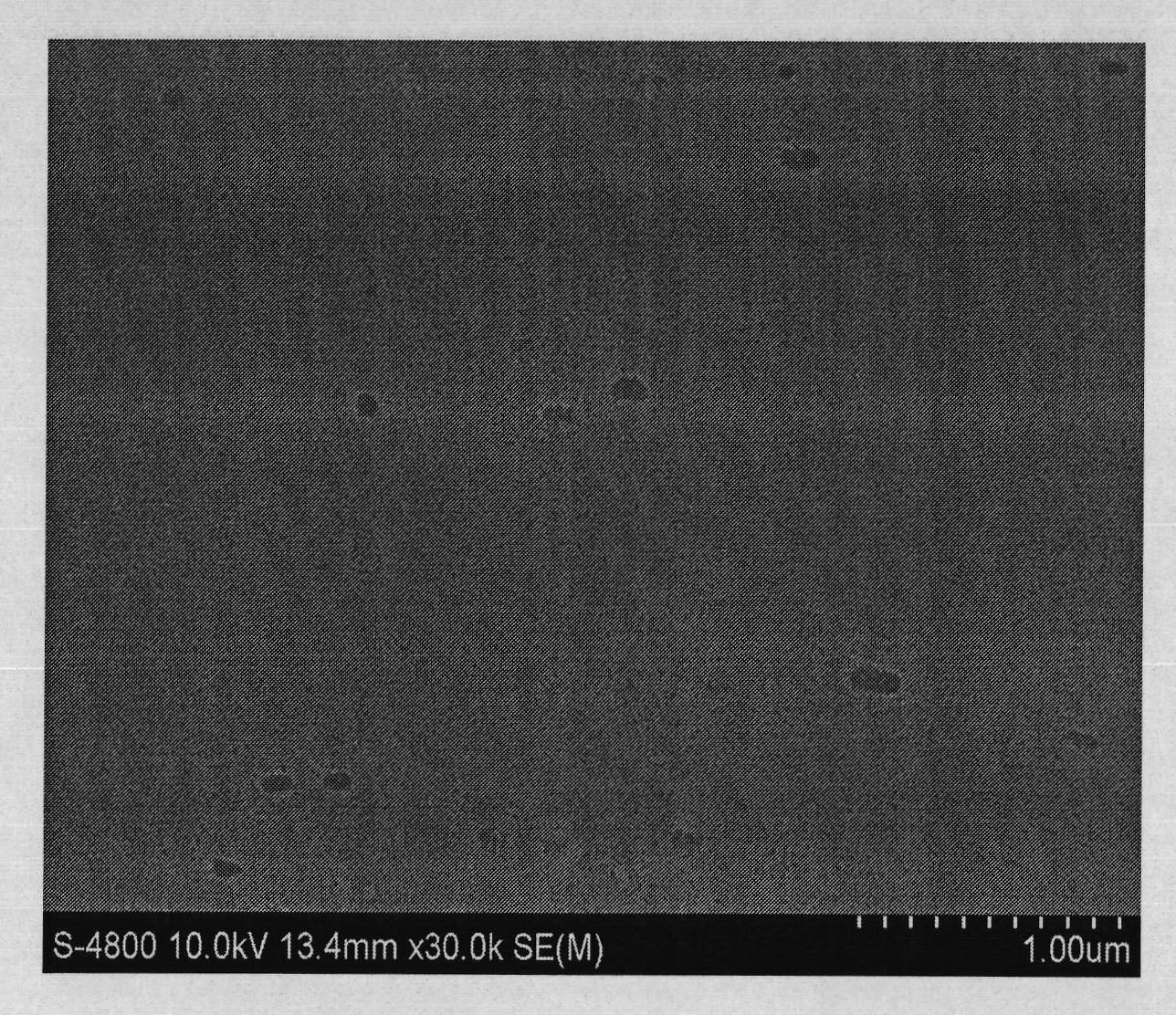

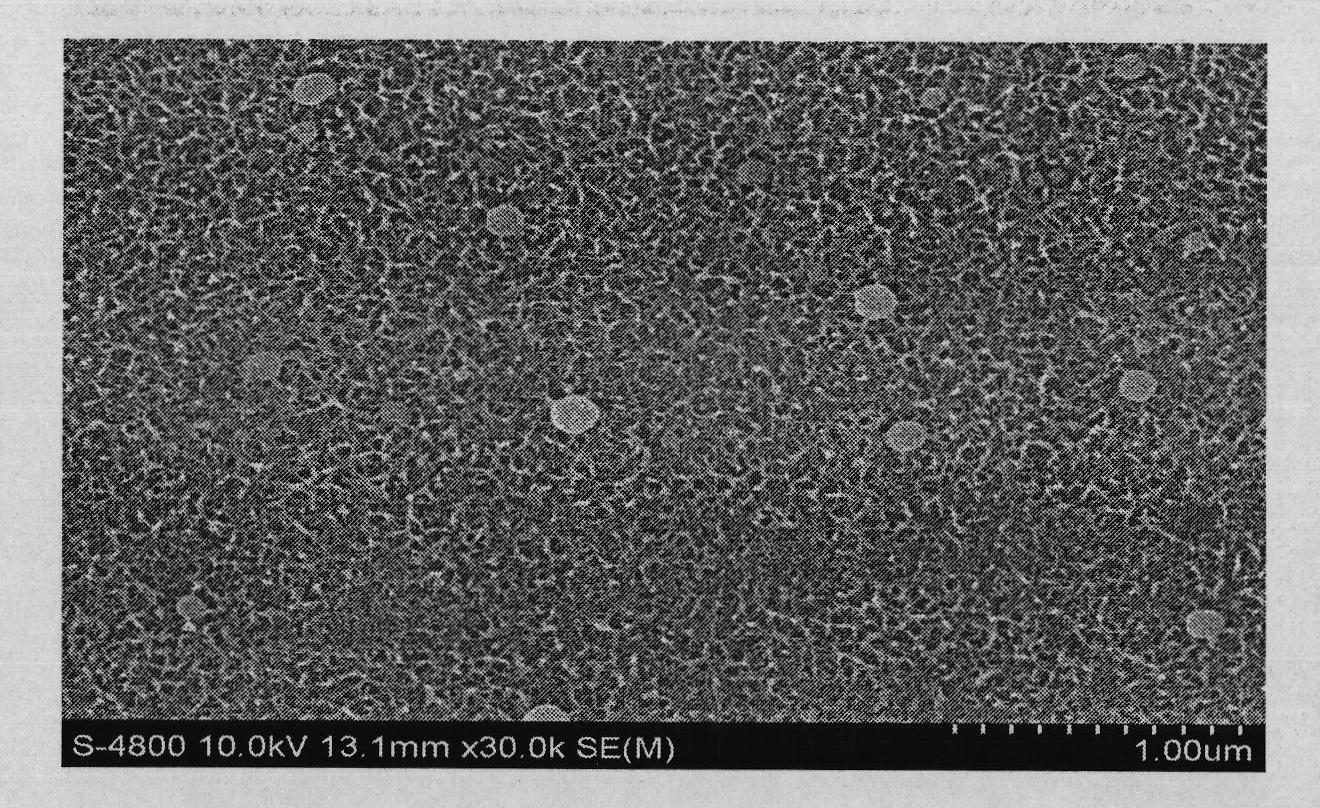

[0041] The thickness of the anodized film on the surface of the LY11 alloy measured by a vortex thickness gauge is 3 μm. The morphology of the anodized film was observed with a scanning electron microscope (Hitachi S-4800 SEM). figure 2 As shown in the figure, there are holes in the anodized film.

[0042] Step 2: Prepare corrosion inhibiting sealing solution

[0043] The corrosion inhibition blocking solution is to dissolve 10g of ammonium adipate and 10μg of 2-mercaptobenzothiazole in 100ml of deionized water at a temperature of 25°C, and measure the pH value with the FE20 model FiveEasy pH meter produced in Switzerland. 7.0;

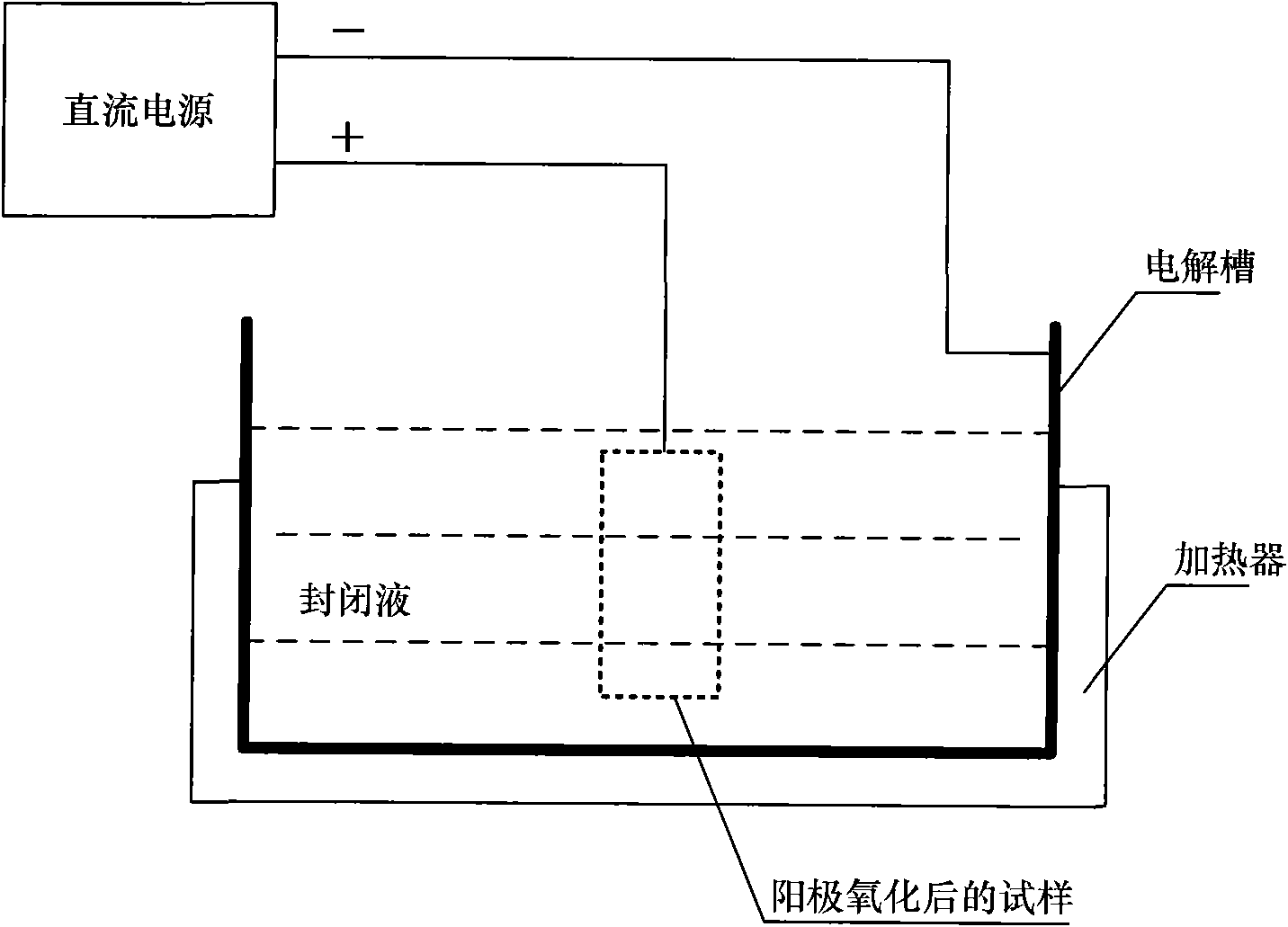

[0044] The third step: closed processing

[0045] (A) Add the corrosion-inh...

Embodiment 2

[0055] The first step: sample selection

[0056] The sample is LC5 alloy treated by boric acid-sulfuric acid anodizing process (U.S. Pat. No. 4,894, 127, Jan. 16, 1990), with a size of 100mm×50mm×2.5mm;

[0057] Step 2: Prepare corrosion inhibiting sealing solution

[0058] The corrosion-inhibiting blocking solution is to dissolve 5 g of ammonium adipate and 50 μg of benzotriazole in 100 ml of deionized water at a temperature of 40° C., and measure the pH value to 6.8 with a pH meter;

[0059] The third step: closed processing

[0060] (A) Add the environment-friendly corrosion-inhibiting sealing solution prepared in the second step into the stainless steel electrolytic cell, and the consumption of the corrosion-inhibiting sealing solution is 2 / 3 of the volume of the electrolytic cell;

[0061] (B) heating the corrosion inhibiting sealing solution to 100°C;

[0062] (C) The sample selected in the first step is completely immersed in the corrosion-inhibiting sealing solution...

Embodiment 3

[0066] The first step: sample selection

[0067] The sample is LY17 alloy treated according to the People's Republic of China Aviation Industry Standard "Sulfuric Acid Anodizing Process for Aluminum and Aluminum Alloys" (HB / Z233-93), with a size of 100mm×50mm×2.5mm;

[0068] Step 2: Prepare corrosion inhibiting sealing solution

[0069] The corrosion inhibition sealing solution is to dissolve 15g of ammonium adipate and 45 μg of quinaldicic acid in 100ml of deionized water at a temperature of 30°C, and measure the pH value to 7.2 with a pH meter;

[0070] The third step: closed processing

[0071] (A) Add the corrosion-inhibiting sealing solution prepared in the second step into the stainless steel electrolytic cell, and the consumption of the corrosion-inhibiting sealing solution is 2 / 3 of the volume of the electrolytic cell;

[0072] (B) heating the corrosion inhibiting sealing solution to 90°C;

[0073] (C) The sample selected in the first step is completely immersed in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com