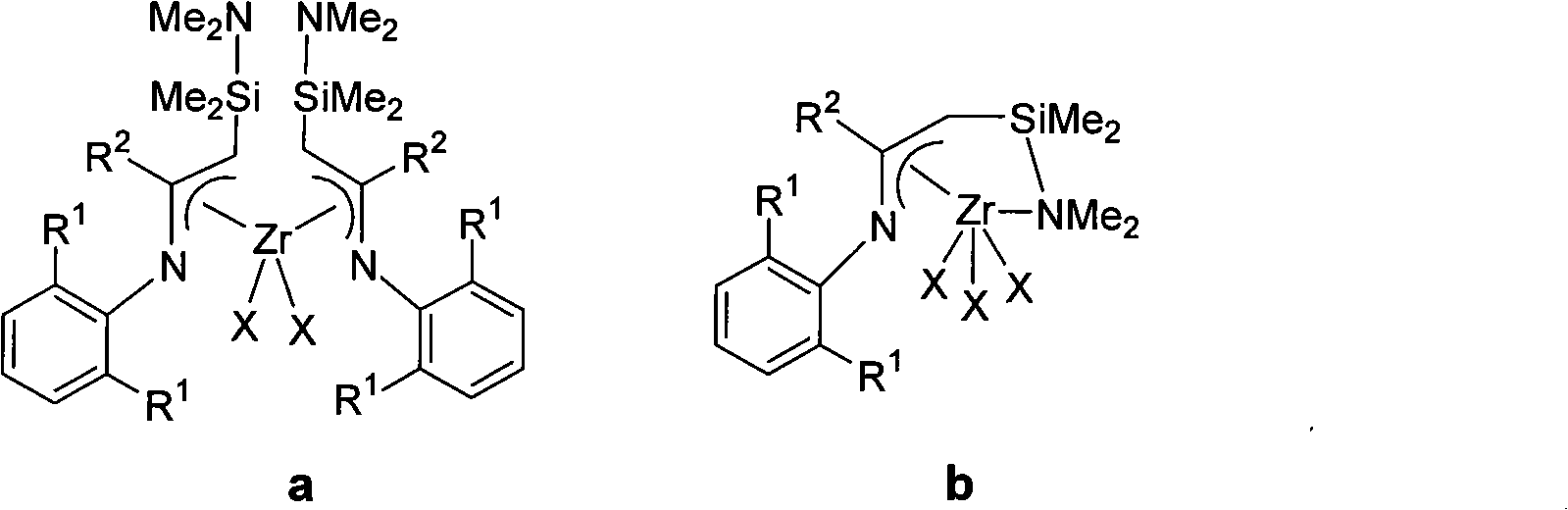

Amino-silicone bridge nitrogen-blending allyl zirconium catalyst and preparation method and application thereof

A technology of heteroallyl zirconium and heteroallyl lithium, which is applied in the field of ethylene polymerization IVB transition metal catalyst, can solve the problems of complicated preparation of raw materials, limited application and promotion, low catalytic activity, etc., and achieves simple and easy-to-obtain raw materials and high Catalytic activity, effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Preparation of lithium salt

[0021] Under the protection of nitrogen, under the acetone bath, lithium diisopropylamide (0.21g, 2mmol) was added to N-phenylethyl-2,6-diisopropylbenzimine (0.56g, 2mmol) In tetrahydrofuran solution, after reacting for 3 hours, cool down to -78°C again and add magnesium bromide (0.37g, 2mmol). When the solution naturally warms up to room temperature, keep stirring for 8 hours, vacuum dry, wash with n-hexane, and recrystallize The tetrahydrofuran complex A1 of 2,6-diisopropyl-N-styrylanilinomagnesium bromide is obtained. Under the protection of nitrogen, under the ice-water bath, dimethylaminodimethylsilyl chloride (0.3ml, 2mmol) was slowly added to the tetrahydrofuran solution of A1. After the solution was naturally warmed to room temperature, the reaction was kept stirring for 6 hours. Extraction with toluene gave N-(2-dimethylaminodimethylsilyl-1-styryl)-2,6-diisopropylaniline neutral compound B1 as an oil. Then under the protectio...

Embodiment 2

[0028] (1) The preparation of lithium salt is the same as in Example 1.

[0029] (2) Preparation of catalyst b1: the Schlenk bottle is evacuated and led to N 2 After three replacements, C1 (0.81g, 2mmol) and 25ml of tetrahydrofuran were added, and ZrCl was added at -78°C 4 (0.45g, 2mmol), return to room temperature under stirring and react for 24 hours, vacuum dry, add 50 ml of dichloromethane, filter, concentrate, wash with n-hexane, crystallize in tetrahydrofuran and dichloromethane (1:3), and obtain light yellow crystals Compound b1 1.03 g, yield: 87%. Decomposition temperature: 167-169°C. Elemental Analysis Theoretical Value C 24 h 35 Cl 3 N 2 SiZr: C, 49.89; H, 6.06; N, 4.85; Found: C, 49.87; H, 6.09; N, 4.83%. 1 H NMR (300MHz C 6 D. 6 )δ-0.02, 0.33(q, 6H, Si(CH 3 ) 2 ), 0.56, 0.93, 1.19-1.38, 1.67-1.73 (m, 12H, CH(CH 3 ) 2 ), 2.18-2.26(d, 6H, N(CH 3 ) 2 ), 3.79(m, 2H, CH(CH 3 ) 2 ), 4.54(s, 1H, CH), 6.84-6.99(m, 5H, Ph), 7.34-7.37(m, 3H, Aryl). 13 C NMR...

Embodiment 3

[0031] 1. The preparation of catalyst a1 is the same as in Example 1.

[0032] 2. Ethylene polymerization: Dry the 250ml polymerization bottle equipped with a magnetic stirrer at 130°C for 6 hours continuously, vacuumize it while it is hot and use N 2 Air replacement 3 times. Catalyst a1 (4.6 mg, 5 μmol) was added, followed by evacuation and replacement with ethylene twice. Inject a certain amount of toluene (26.6ml) with a syringe, then add methylaluminoxane (1.46mol / L, 3.4ml) to make Al / Zr=1000, at 50°C, keep the ethylene pressure of 1 atmosphere, stir vigorously for 30 minute. Add 5% hydrochloric acid ethanol solution to the reaction solution for neutralization, and a small amount of white solid precipitates out. After filtration it was vacuum dried for 3 hours. Obtained product 0.0075g, polymerization activity: 3.0×10 3 g mol(Zr) -1 h -1 , Melting point of the polymer: 134.4°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com