Method for inactivating tellurium-zinc-cadmium pixel detector electrodes

A detector, cadmium zinc telluride technology, applied in circuits, electrical components, semiconductor devices, etc., to achieve good surface passivation effect, improve passivation effect, and reduce leakage current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

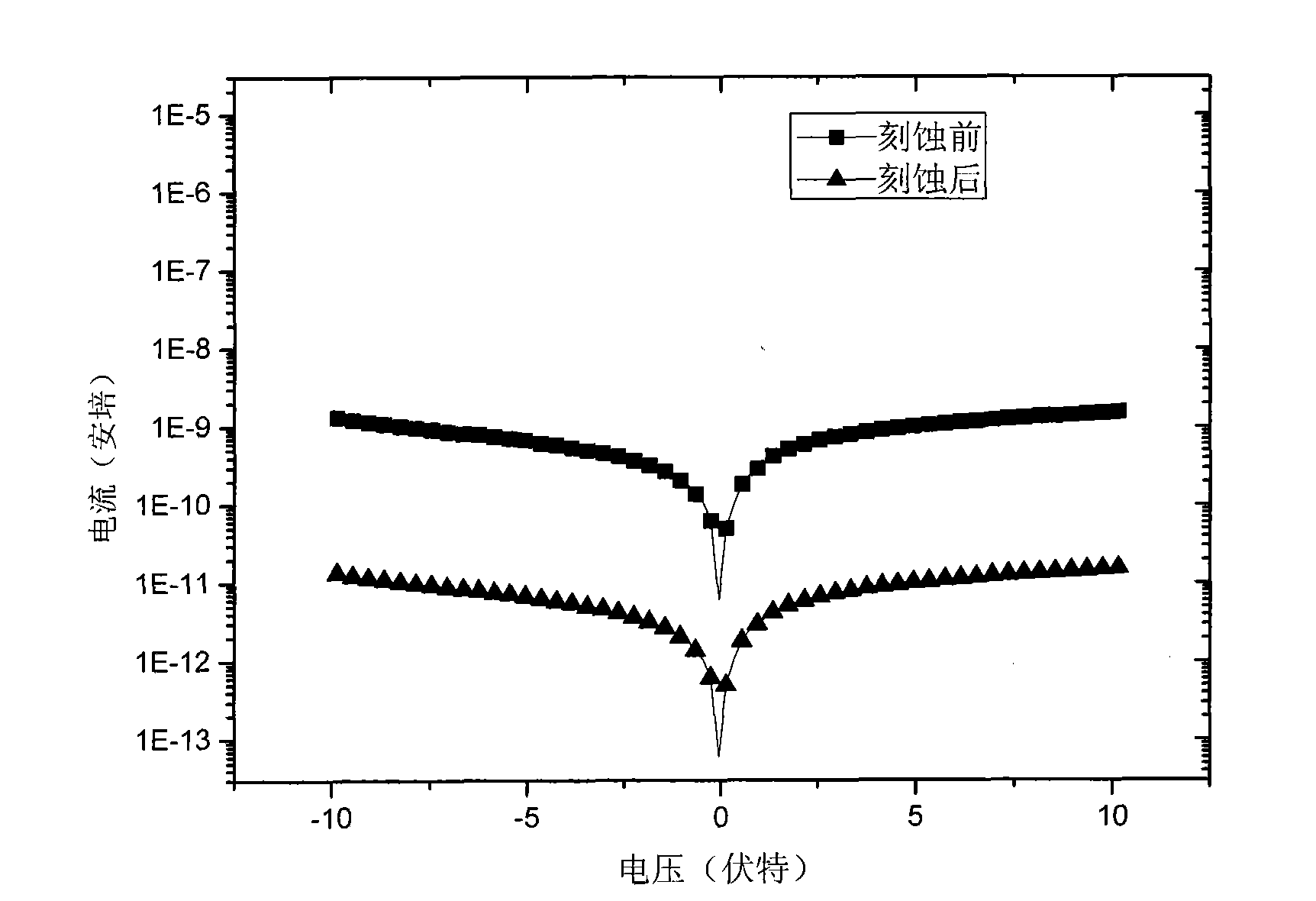

Embodiment 1

[0017] Embodiment 1: the first step, to Cd 0.9 Zn 0.1 The Te crystal is wire-cut, ground, mechanically polished, cleaned and then chemically polished in 2% Br-MeOH to obtain a ready-to-use CdZnTe wafer. Then, the mechanically polished and chemically polished CdZnTe wafers are cleaned, glued, dried, exposed, developed, vacuum evaporated electrodes and peeled off to prepare pixel detector electrodes.

[0018] In the second step, put the prepared pixel detector electrode into a RIE-3 type reactive ion etching machine to evacuate, and the vacuum degree is 0.3333Pa.

[0019] The third step is to adjust the oxygen inflow, the parameter is to adjust the oxygen inflow, and the parameter is 70cm 3 / min.

[0020] The fourth step is to adjust the working air pressure, the parameter is 0.75Pa.

[0021] The fifth step is to adjust the radio frequency power, and its parameter is 10W.

[0022] The sixth step is to start timing etching when the power adjustment is completed. The etching ...

Embodiment 2

[0024] Embodiment 2: the first step, to Cd 0.9 Zn 0.1 The Te crystal is wire-cut, ground, mechanically polished, cleaned and then chemically polished in 2% Br-MeOH to obtain a ready-to-use CdZnTe wafer. Then, the mechanically polished and chemically polished CdZnTe wafers are cleaned, glued, dried, exposed, developed, vacuum evaporated, and stripped to prepare CdZnTe pixel detector electrodes.

[0025] In the second step, the prepared pixel detector electrodes are put into a RIE-3 type reactive ion etching machine for vacuuming, and the vacuum degree is 0.3999Pa.

[0026] The third step is to adjust the oxygen inflow, the parameter is to adjust the oxygen inflow, and the parameter is 80cm 3 / min.

[0027] The fourth step is to adjust the working air pressure, the parameter is 1.0Pa

[0028] The fifth step is to adjust the RF power, the parameter is 9W.

[0029] The sixth step is to start timing etching when the power adjustment is completed. The etching time is 50 minutes...

Embodiment 3

[0031] Embodiment 3: the first step, to Cd 0.9 Zn 0.1 The Te crystal is wire-cut, ground, mechanically polished, cleaned and then chemically polished in 3% Br-MeOH to obtain a ready-to-use CdZnTe wafer. Then, the mechanically polished and chemically polished CdZnTe wafer is cleaned, glued, dried, exposed, developed, vacuum evaporated electrode and peeled off to prepare the pixel detector electrode.

[0032] In the second step, the prepared pixel detector electrodes are put into a RIE-3 type reactive ion etching machine for vacuuming, and the vacuum degree is 0.3333Pa.

[0033] The third step is to adjust the oxygen inflow, the parameter is to adjust the oxygen inflow, and the parameter is 75cm 3 / min.

[0034] The fourth step is to adjust the working air pressure, the parameter is 0.5Pa

[0035] The fifth step is to adjust the RF power, the parameter is 8W.

[0036]The sixth step is to start timing etching when the power adjustment is completed. The etching time is 35 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com