Preparation method of Cu2ZnSnS4 semiconductor material

A technology of semiconductor and ammonium sulfide, which is applied in the field of preparation of Cu2ZnSnS4 semiconductor materials, can solve the problems of vacuum or gas protection in the preparation process, complex vulcanization process, difficult control of product stoichiometry, etc., to achieve easy control and adjustment, simple preparation process, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

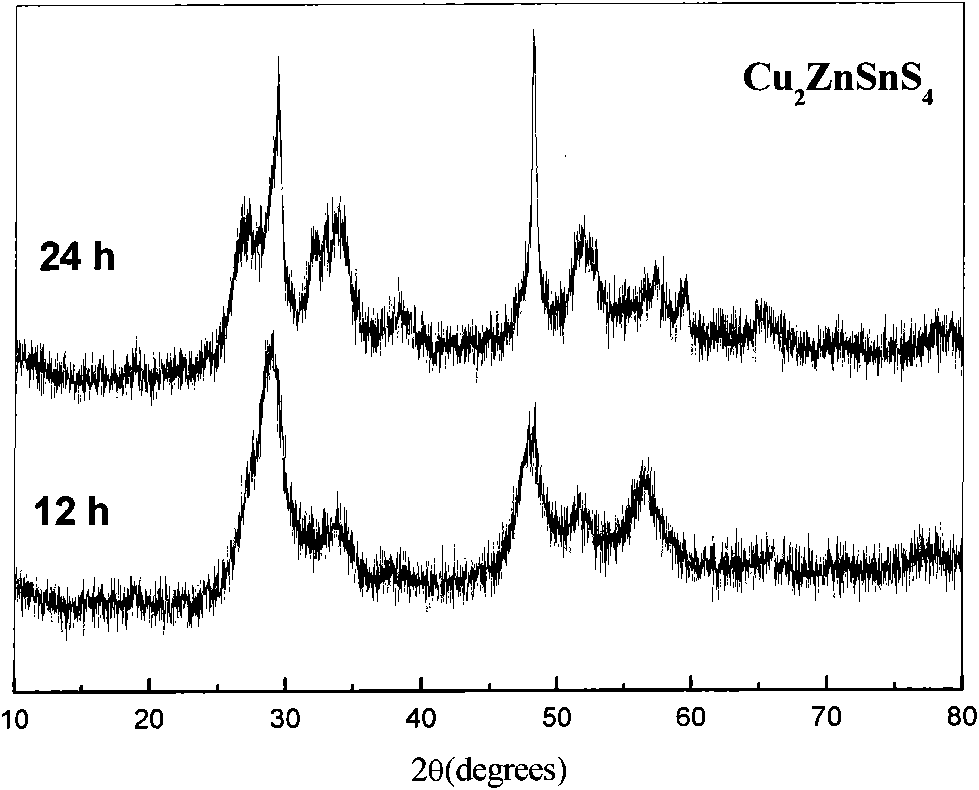

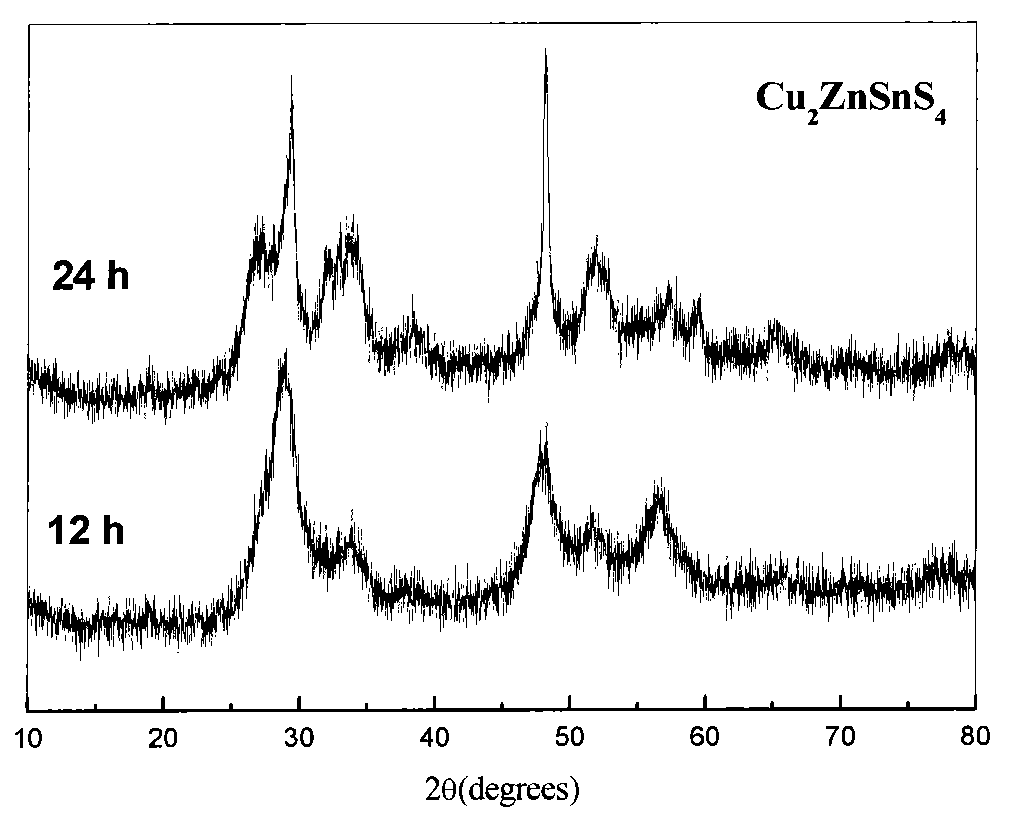

Image

Examples

Embodiment 1

[0015] (1), 8.00g ammonium sulfide solution (sulfur content 8%) and 92.0g distilled water are mixed uniformly, suction filtration, obtain filtrate (A);

[0016] (2) Dissolve 1.12g of stannous chloride in 8.00ml of concentrated hydrochloric acid, dilute with 100.0g of distilled water, then add 0.54g of zinc chloride and 1.87g of copper chloride, stir evenly, and filter with suction. Add the filtrate (A) dropwise while magnetically stirring. After the dropwise addition, continue stirring for 30 min, filter with suction, and wash twice with 100 mL of distilled water to obtain a filter cake;

[0017] (3) The filter cake was mixed with 25.0 g of distilled water, then transferred to an autoclave, and kept at 220° C. for 72 hours. After cooling to room temperature, the resulting mixture was rotary evaporated (85 °C, 0.09 MPa) to remove distilled water to obtain a crude product, which was dried in vacuum at 70 °C for 6 h to obtain Cu 2 ZnSnS 4 semiconductors.

Embodiment 2

[0019] Dissolve 1.12g of stannous chloride in 8.00ml of concentrated hydrochloric acid, dilute with 100.0g of distilled water, then add 0.82g of zinc chloride and 1.87g of copper chloride, stir evenly, filter with suction, and drop the filtrate (B) while stirring magnetically Add the filtrate (A), after the dropwise addition, continue to stir for 30 min, filter with suction, and wash twice with 100 mL of distilled water to obtain a filter cake; others are the same as in Example 1.

Embodiment 3

[0021] Dissolve 1.12g of stannous chloride in 8.00ml of concentrated hydrochloric acid, dilute with 100.0g of distilled water, then add 0.68g of zinc chloride and 1.87g of copper chloride, stir evenly, filter with suction, and drop the filtrate (B) while stirring magnetically Add the filtrate (A), after the dropwise addition, continue to stir for 30 min, filter with suction, and wash twice with 100 mL of distilled water to obtain a filter cake; others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com