Numerical control milling process method of thin-walled part die cavity

A technology of thin-walled parts and CNC milling, which is applied to metal processing equipment, milling cutters, milling machine equipment, etc., can solve problems such as reduced work efficiency, poor part size consistency, and out-of-tolerance dimensions, so as to improve part processing efficiency and improve product quality. The effect of improving quality and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

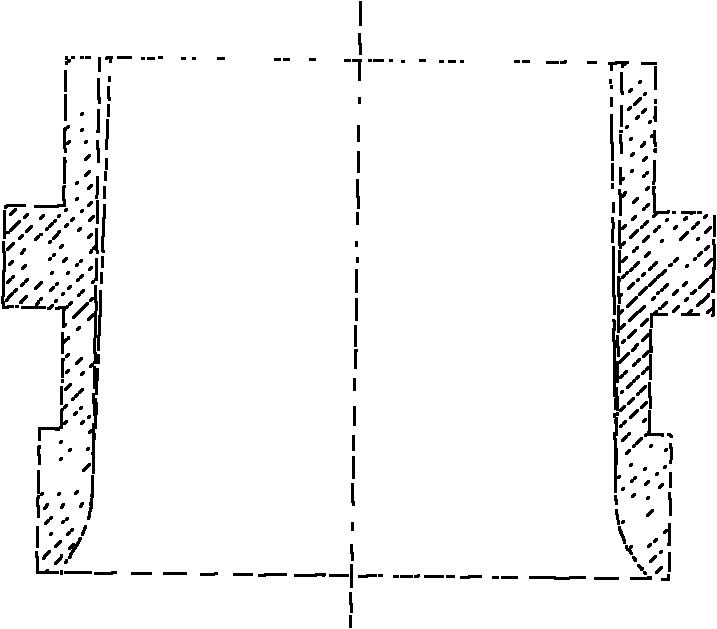

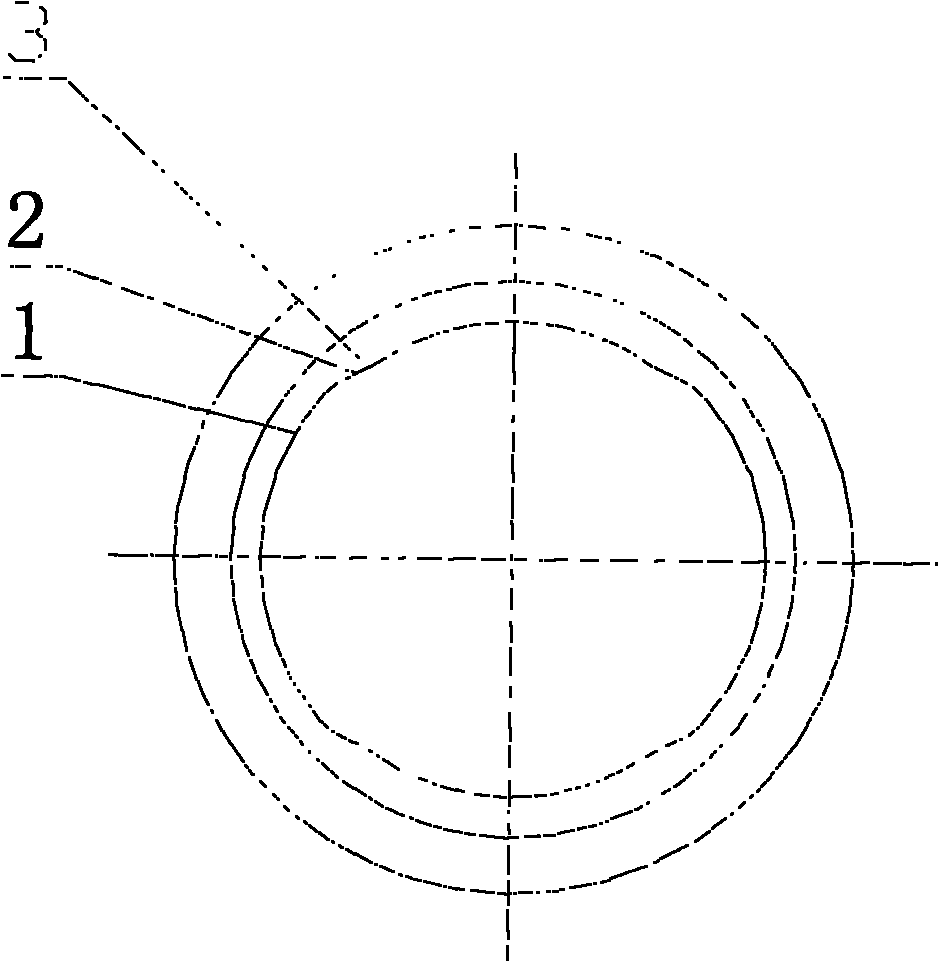

Embodiment 1

[0011] see figure 1 , the material of the thin-walled part is 40CrNiMoA, the diameter of the outer cylinder of the thin-walled part is 156mm, the length is 170mm, the roughness Ra=1.6μm, the radius of the inner hole is 55mm, the generatrix is formed by tangent to the curved surface of the arc, and the minimum wall thickness is 3.5mm, the two cavities to be processed are symmetrical grooves on the inner hole of the thin-walled part, the radius of the cavity is 55.75mm, and a concave arc with a diameter of 32mm and a diameter of 10mm There are four convex arcs connected tangentially, and the concave arcs and convex arcs are also connected tangentially. The cavity length is 160 mm and the roughness Ra is 3.2 μm. It is processed by XK716 powerful CNC milling machine, and the thin-walled parts are positioned and clamped by the outer cylinder of the thin-walled parts. Since the arc diameter of the smallest groove of the thin-walled part cavity is 32mm, the inserting blade with a d...

Embodiment 2

[0013] see figure 1 , the material of the thin-walled part is 40CrNiMoA, the diameter of the outer cylinder of the thin-walled part is 156mm, the length is 170mm, the roughness Ra=1.6μm, the radius of the inner hole is 55mm, the generatrix is formed by tangent to the curved surface of the arc, and the minimum wall thickness is 3.5mm, the two cavities to be processed are symmetrical grooves on the inner hole of the thin-walled part, the radius of the cavity is 55.75mm, and a concave arc with a diameter of 32mm and a diameter of 10mm There are four convex arcs connected tangentially, and the concave arcs and convex arcs are also connected tangentially. The cavity length is 160 mm and the roughness Ra is 3.2 μm. It is processed by XK716 powerful CNC milling machine, and the thin-walled parts are positioned and clamped by the outer cylinder of the thin-walled parts. Since the arc diameter of the smallest groove of the thin-walled part cavity is 32mm, the inserting blade with a d...

Embodiment 3

[0015] see figure 1 , the material of the thin-walled part is 40CrNiMoA, the diameter of the outer cylinder of the thin-walled part is 156mm, the length is 170mm, the roughness Ra=1.6μm, the radius of the inner hole is 55mm, the generatrix is formed by tangent to the curved surface of the arc, and the minimum wall thickness is 3.5mm, the two cavities to be processed are symmetrical grooves on the inner hole of the thin-walled part, the radius of the cavity is 55.75mm, and a concave arc with a diameter of 32mm and a diameter of 10mm There are four convex arcs connected tangentially, and the concave arcs and convex arcs are also connected tangentially. The cavity length is 160 mm and the roughness Ra is 3.2 μm. It is processed by XK716 powerful CNC milling machine, and the thin-walled parts are positioned and clamped by the outer cylinder of the thin-walled parts. Since the arc diameter of the smallest groove of the thin-walled part cavity is 32mm, the inserting blade with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com