Extraction method for extracting vanadium pentoxide from low grade oxidized type navajoite

A technology of vanadium pentoxide and oxidized type, which is applied in the field of extracting vanadium pentoxide from low-grade oxidized type vanadium ore, can solve the problems of serious environmental pollution, high production cost, compressed smelting material handling capacity, etc., and achieves the goal of overcoming Environmental pollution problems, improving grades, and reducing the effect of smelting investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The raw ore is the surface ore of the Tangtuo mining area of Sinosteel Hunan Phoenix Mining Co., Ltd., which is a low-grade oxidized vanadium ore, and the recyclable valuable minerals in the ore are mainly vanadium pentoxide. The content of vanadium pentoxide in the ore is 0.93%, and the production cost of directly extracting vanadium from raw ore is extremely high, making it difficult for enterprises to make profits. The invention aims at adopting ore dressing to enrich vanadium in this ore, and then smelting and recovering vanadium.

[0029] Raw materials: surface ore of Tangtuo mining area of Sinosteel Hunan Phoenix Mining Co., Ltd., its main chemical composition is (%):

[0030] V 2 o 5

TC

SiO 2

Al 2 o 3

S

0.93

2.00

72.41

9.27

0.27

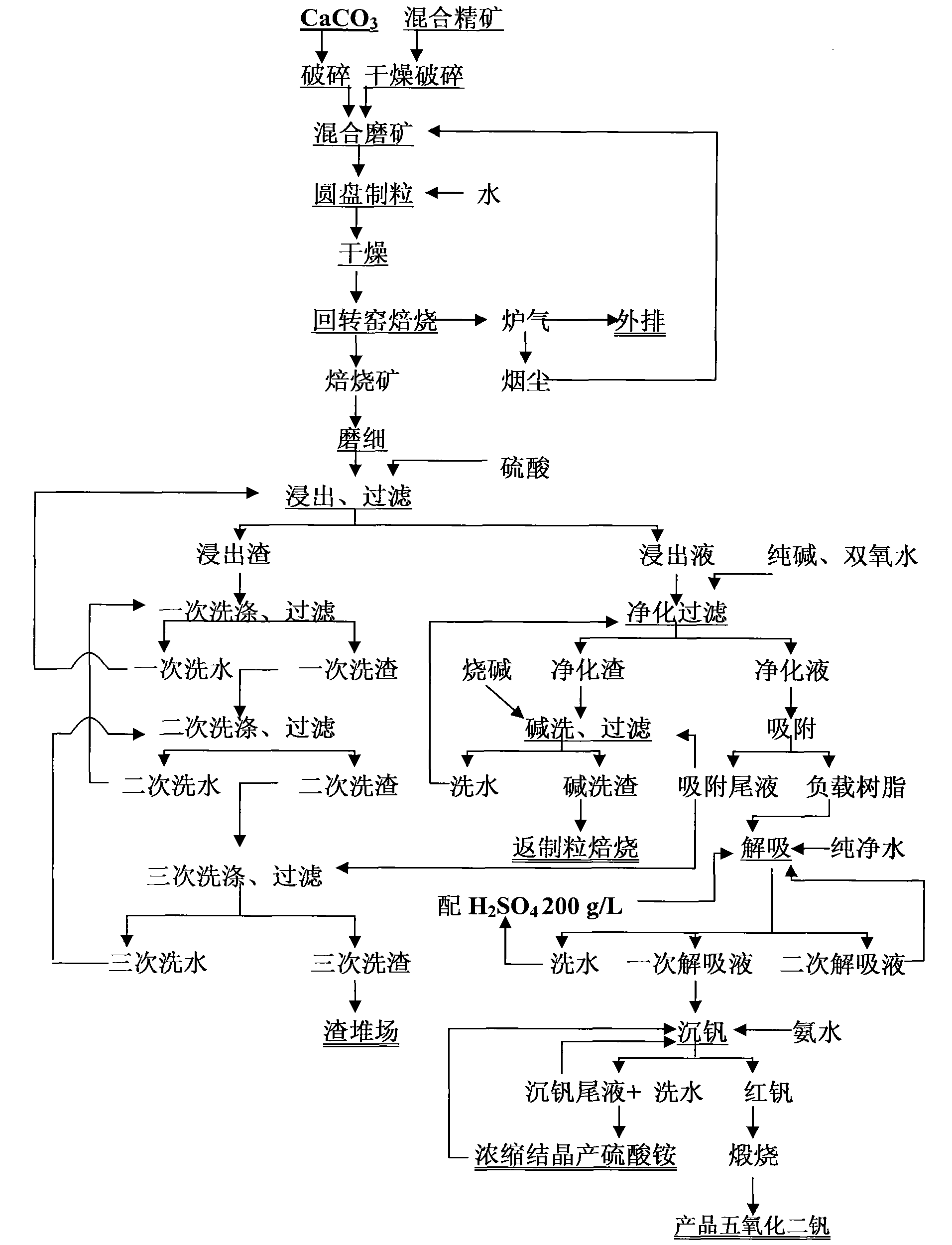

[0031] Process flow:

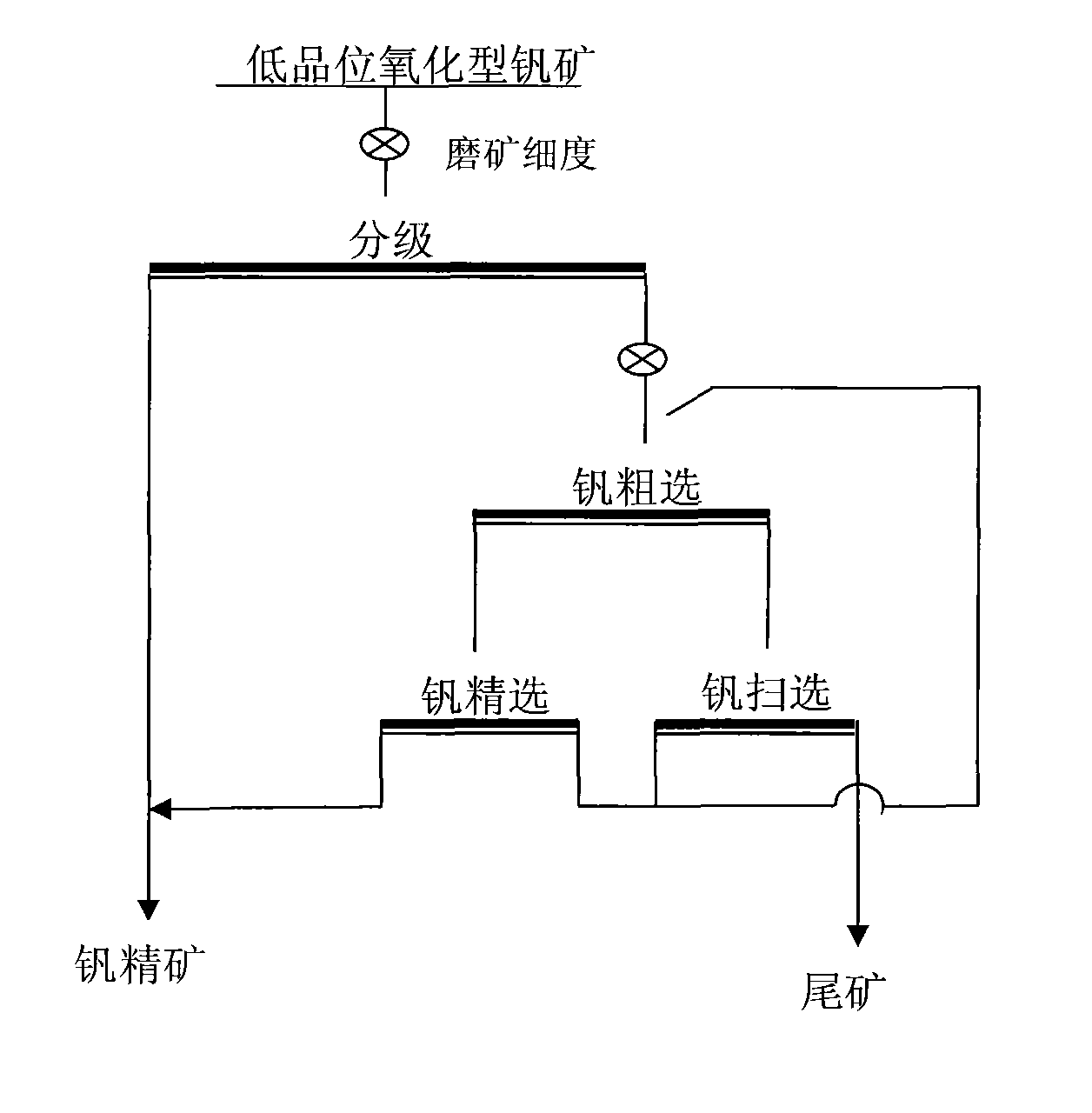

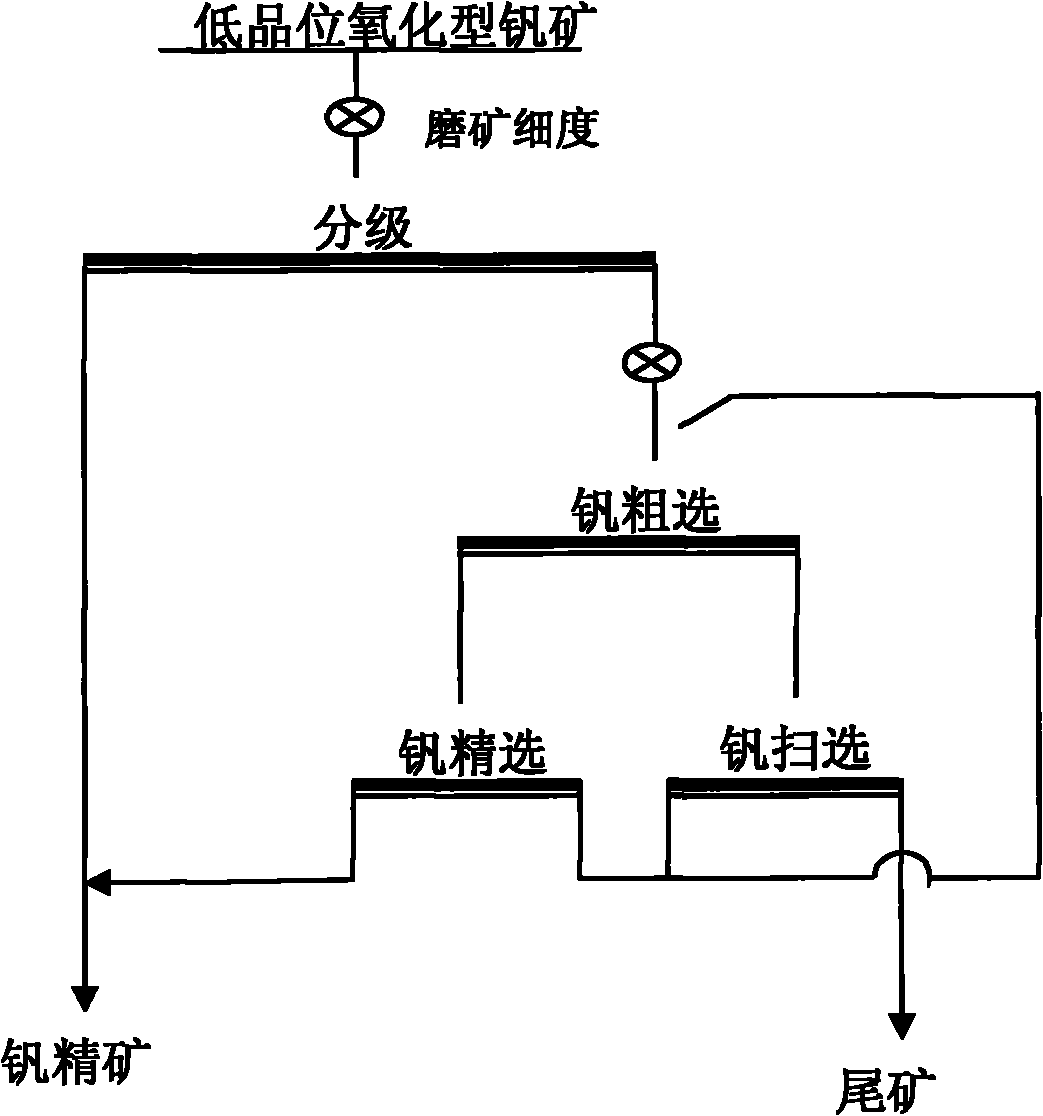

[0032] 1) Crush low-grade oxidized vanadium ore raw ore to a particle size of 10mm-15mm, and then ball mill until the fineness is -0.074...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com