Application of limonite as adhesive and pellet preparation method

A technology of pelletizing ore and limonite, which is applied in the field of metal smelting, can solve the problems affecting the pelletizing performance of iron ore powder, the quality of pellets, the decline in production, and the reduction of iron grade in pellets, so as to achieve the goal of ore blending The effect of reducing cost, improving grade and reducing the amount of blast furnace slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

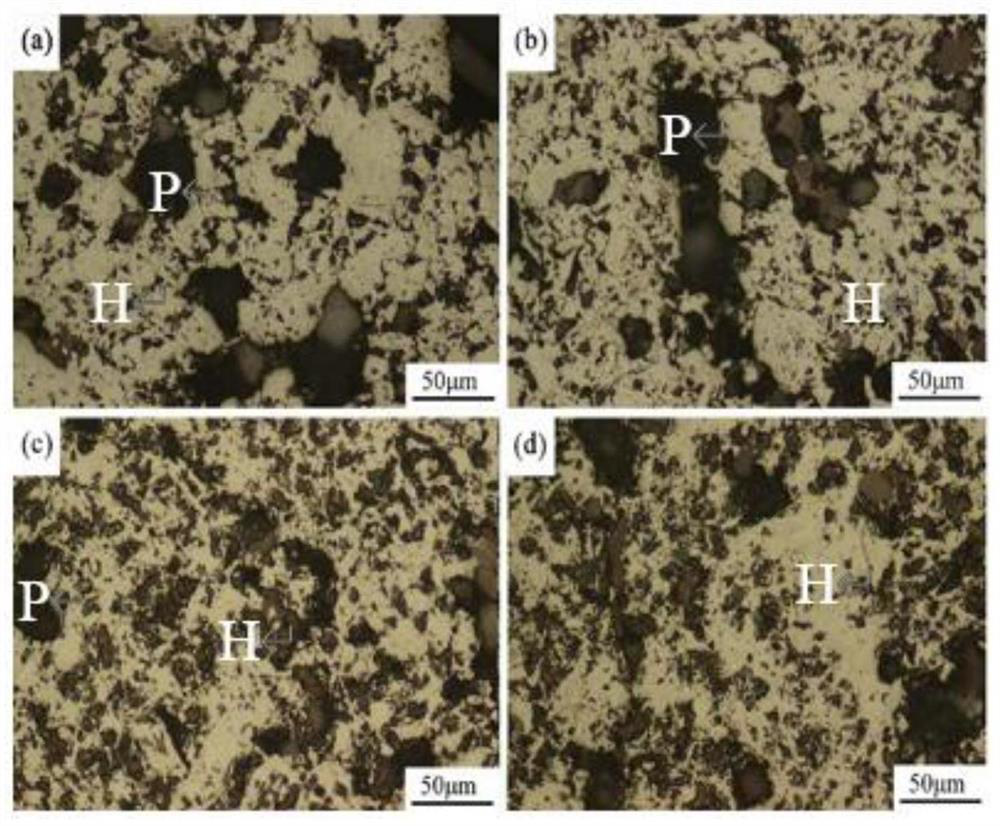

[0037] The invention provides a method for preparing pellets. The pellet preparation method includes the step of adding the above-mentioned limonite powder into magnetite powder as a binder.

[0038] Preferably, the preparation method comprises the following steps:

[0039] Step 1) raw material preparation and mixing: mixing magnetite powder dried at a certain temperature, limonite powder crushed to a certain particle size and bentonite to obtain a mixed material;

[0040] Step 2) Pelletizing: Put the mixed material obtained in step 1) into a pelletizing device, and pelletize under certain operating conditions to obtain green pellets;

[0041] Step 3) drying: drying the green balls obtained in step 2) under certain conditions to obtain dry balls;

[0042] Step 4) preheating: preheating the dry ball obtained in step 3) at a certain temperature to obtain a preheated ball;

[0043] Step 5) roasting: roasting the preheated ball obtained in step 4) at a certain temperature to obt...

Embodiment 1

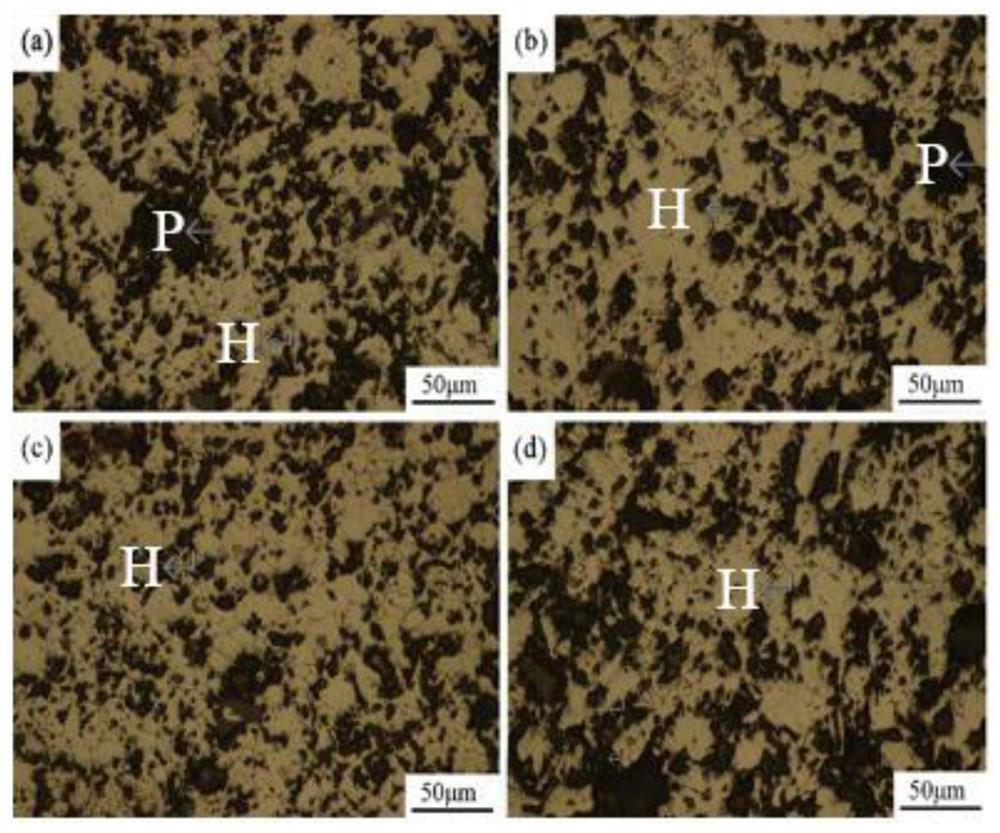

[0097] The pellet preparation method of the present embodiment adopts the following steps:

[0098] Step 1) Raw material preparation and mixing: mix the magnetite powder dried at 110°C, the limonite powder crushed to less than 200 meshes, and bentonite to obtain a mixed material, the mass of the first magnetite powder in the mixed material The percentage is 64%, the mass percentage of the second magnetite powder is 32%, the addition of limonite powder is 4%, and the addition of bentonite is the first magnetite powder, the second magnetite powder and limonite 1.5% of the sum of powder mass;

[0099] Step 2) Pelletizing: Put the mixed material obtained in step 1) into a pelletizing device, and pelletize in a pelletizing disk with a diameter of 1m, an inclination angle of 45°, and a rotating speed of 30r / min. The ball was formed for 3 minutes, the fog water was grown for 8 minutes, and the water was not compacted for 10 minutes to obtain a green ball;

[0100] Step 3) drying: d...

Embodiment 2

[0106] The pellet preparation method of the present embodiment adopts the following steps:

[0107] Step 1) Raw material preparation and mixing: mix the magnetite powder dried at 110°C, the limonite powder crushed to less than 200 meshes, and bentonite to obtain a mixed material, the mass of the first magnetite powder in the mixed material The percentage is 64%, the mass percentage of the second magnetite powder is 32%, the addition of limonite powder is 4%, and the addition of bentonite is the first magnetite powder, the second magnetite powder and limonite 1.5% of the sum of powder mass;

[0108] Step 2) Pelletizing: Put the mixed material obtained in step 1) into a pelletizing device, and pelletize in a pelletizing disk with a diameter of 1m, an inclination angle of 45°, and a rotating speed of 30r / min. The ball was formed for 3 minutes, the fog water was grown for 8 minutes, and the water was not compacted for 10 minutes to obtain a green ball;

[0109] Step 3) drying: d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mana absorption | aaaaa | aaaaa |

| Expansion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com