A kind of preparation method of steel fiber rubber steel slag recycled aggregate concrete

A technology of recycled aggregate and steel fiber, applied in the field of construction engineering materials, can solve the problems of less than 30% recycling rate, difficult degradation of waste rubber, waste of effective energy, etc., to improve energy consumption, reduce thermal conductivity, The effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

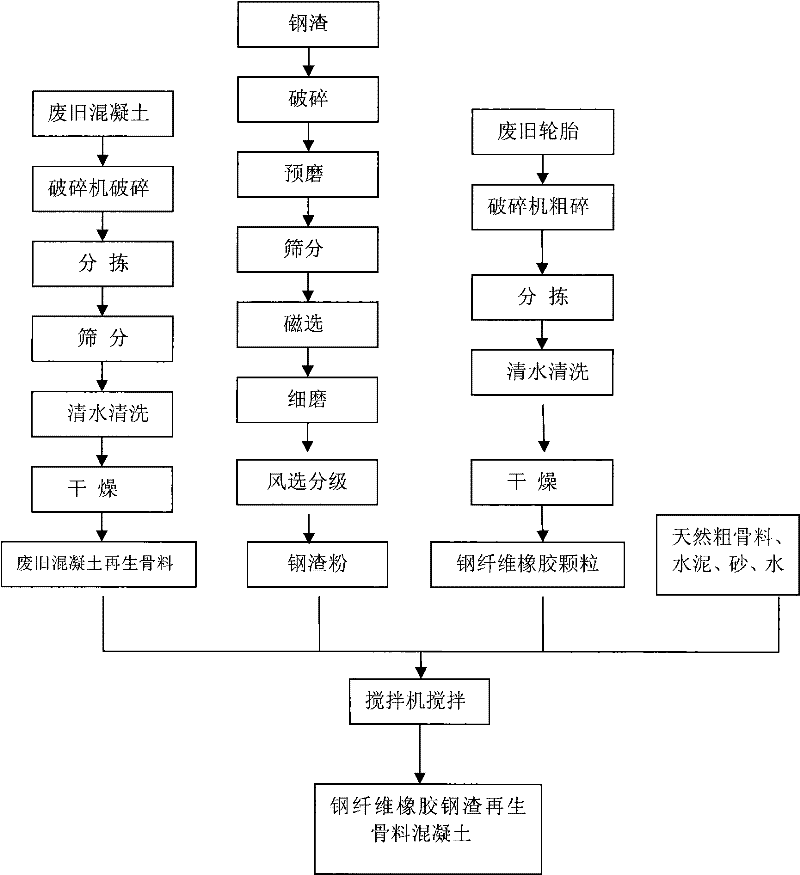

[0025] The implementation steps of the present invention are as follows:

[0026] (1) The recycled aggregate of waste concrete is broken by the waste concrete through the crusher, and the debris other than concrete is sorted, and then passed through a mesh screen to screen out the recycled aggregate with a size ranging from 5mm to 30mm, and it is cleaned with water After that, let it dry naturally.

[0027] (2) Steel fiber rubber particles are obtained from waste tires through a crusher through coarse crushing, sorting, cleaning, and drying. The size is 1 mesh to 5 mesh. The length at which the steel wire is naturally cut off.

[0028] (3) The steel slag is crushed, screened, magnetically separated, air-selected and classified to obtain steel slag powder.

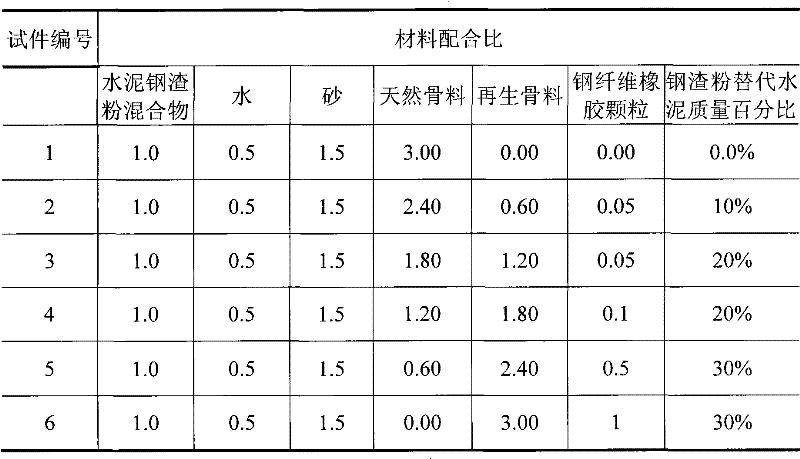

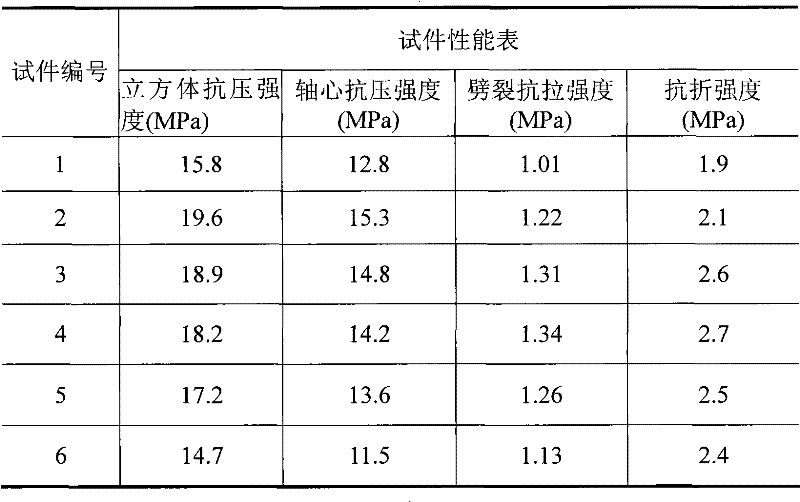

[0029] (4) Pour the mixture of cement and steel slag powder, water, sand, natural coarse aggregate, waste concrete recycled aggregate, and steel fiber rubber particles in a mass ratio of 1:0.5:1.5:0~3:0~3:0.05~1 Put it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com