Fluorine-containing ion exchange membrane with reinforced sacrificial fiber mesh cloth

An ion-exchange membrane and sacrificial fiber technology, applied in the field of fluorine-containing ion-exchange multilayer membranes and their preparation, can solve problems such as reduced mechanical strength, and achieve the effects of high mechanical strength, reduced membrane resistance, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

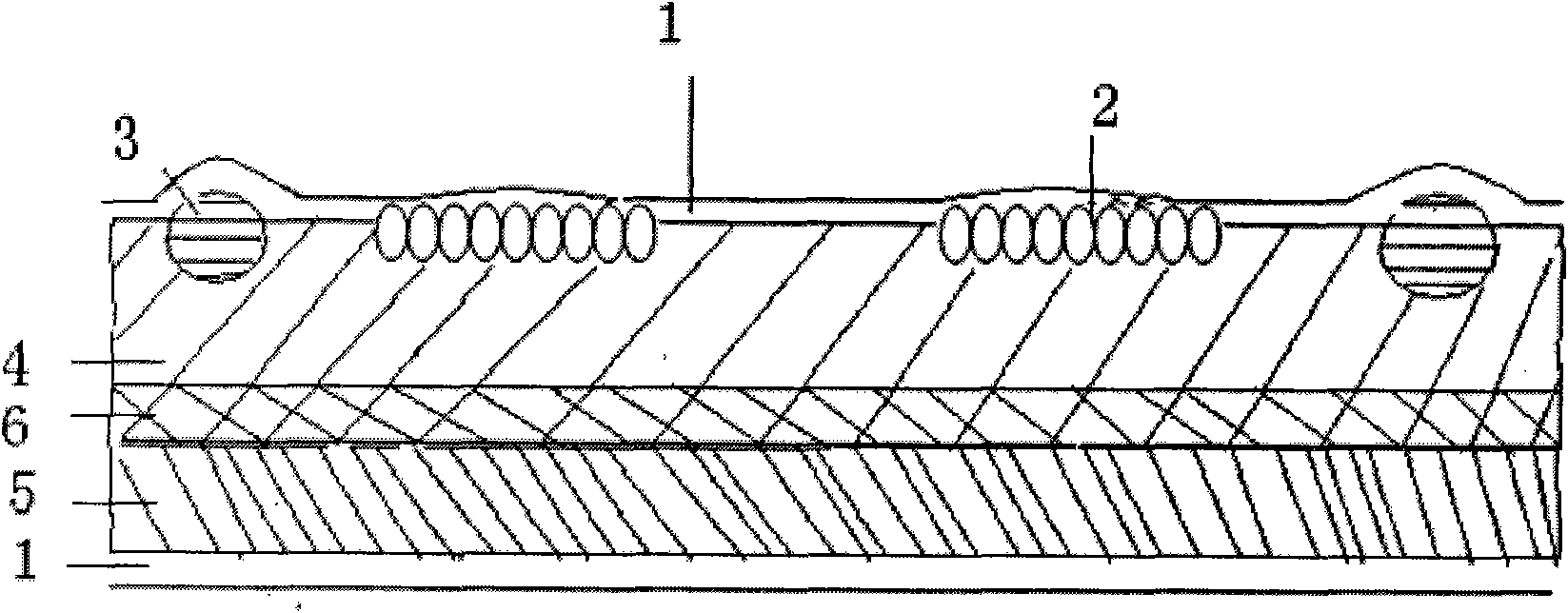

[0055] The polytetrafluoroethylene (PTFE) film is stretched rapidly, and then the stretched film is cut into monofilaments with a fineness of 90 denier; eight polyethylene terephthalate (PET) fibers with a diameter of 10 μm are used The whole is laid flat into a set of yarns. A plain weave fabric was alternately woven in the order of one PTFE thread and two groups of PET yarns, with a weaving density of 15 threads / cm.

[0056] Fluorine-containing resin single film and composite film are prepared by melt-extrusion film forming process and hot pressing process.

[0057] First prepare the film A with thickness of 8 microns with the above-mentioned perfluorocarboxylic acid resin A; prepare the film B with the thickness of 80 microns with the above-mentioned perfluorosulfonic acid resin B; The mass ratio of 1:1 was mixed evenly to prepare a film C with a thickness of 6 microns. Then, various films are stacked in the order of A\C\B for heat press lamination to obtain a multilayer ...

Embodiment 2

[0061] The reinforced mesh was prepared in the same manner as in Example 1, except that 10 polyethylene terephthalate (PET) fibers with a diameter of 10 μm were used to weave as a group of yarns.

[0062] The fluorine-containing ion exchange membrane reinforced by sacrificial fiber mesh was obtained by using the same multilayer membrane and lamination, transformation and coating process as in Example 1. And use the same method of Example 1 to measure its tensile strength, volume expansion rate and electrolytic performance.

Embodiment 3

[0064] The reinforced mesh was prepared in the same manner as in Example 1, except that 9 polyethylene terephthalate (PET) fibers with a diameter of 10 μm were used to weave as a group of yarns.

[0065] The fluorine-containing ion exchange membrane reinforced by sacrificial fiber mesh was obtained by using the same multilayer membrane and lamination, transformation and coating process as in Example 1. And use the same method of Example 1 to measure its tensile strength, volume expansion rate and electrolytic performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com