Quantitative feed electric control pressure reductor, characteristic test system for pressure reductor and automatic test method

A technology of quantitative supply and pressure reducer, which is applied in the testing of machines/engines, machines/structural components, instruments, etc., can solve problems such as low efficiency, achieve accurate test data, improve work efficiency, and save manpower and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

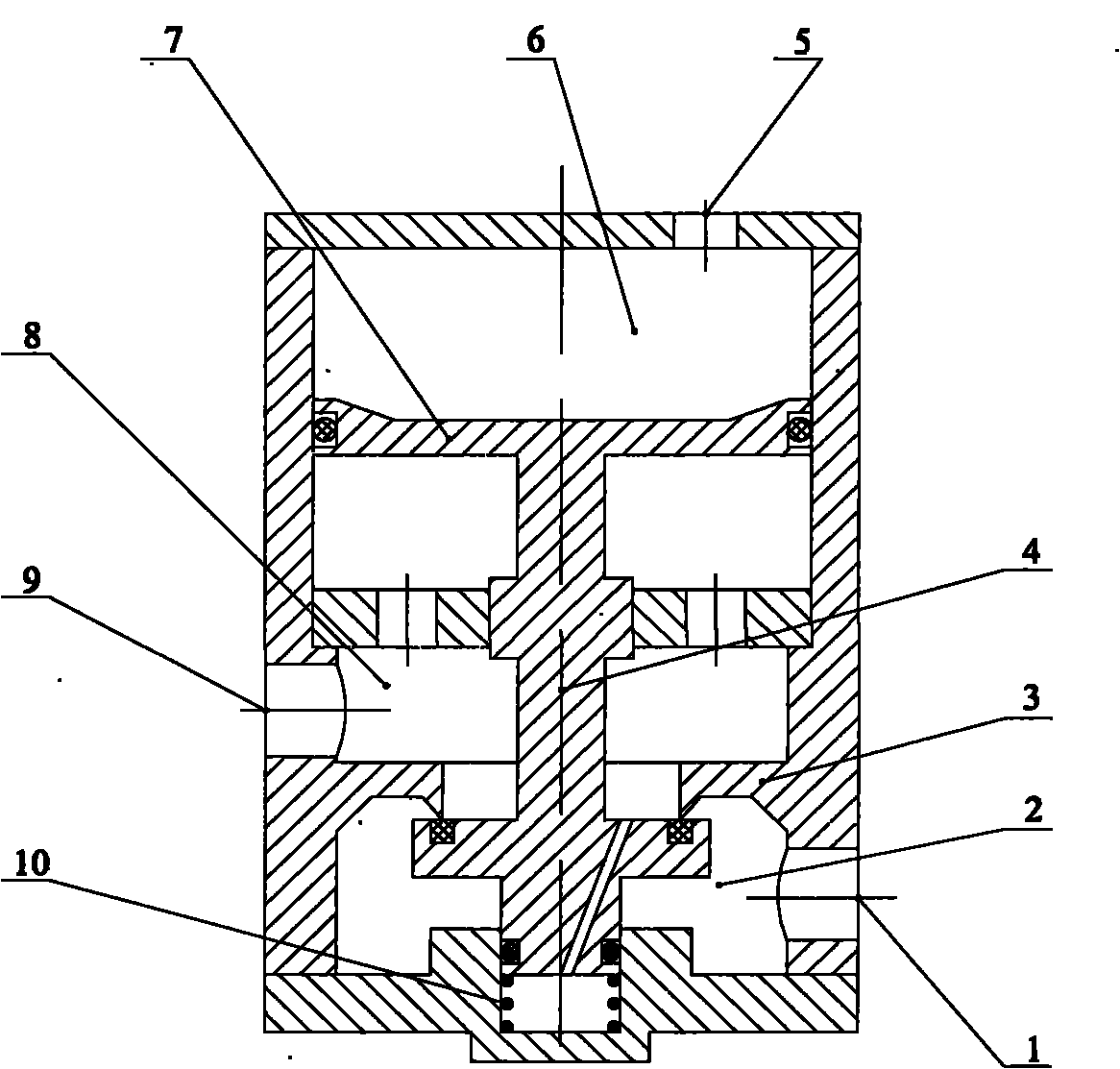

Embodiment Construction

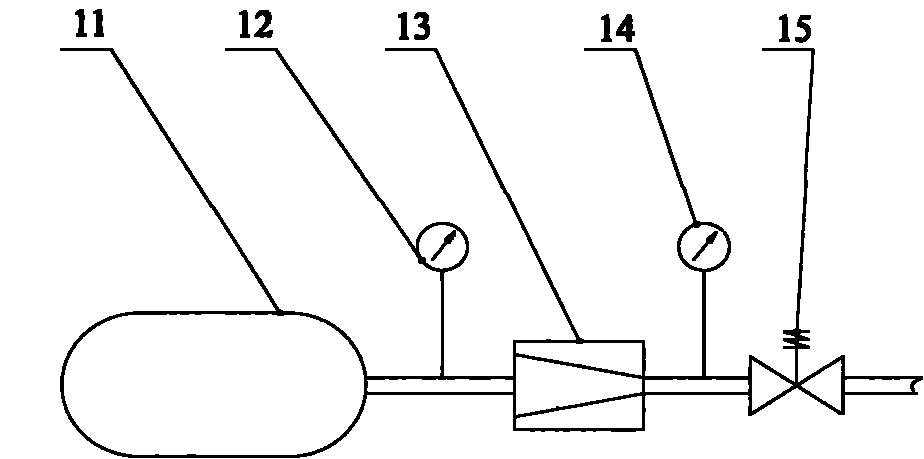

[0032] The automatic test system for the characteristics of the pressure reducer is composed of three parts: the gas supply system, the data acquisition and control circuit, and the control program.

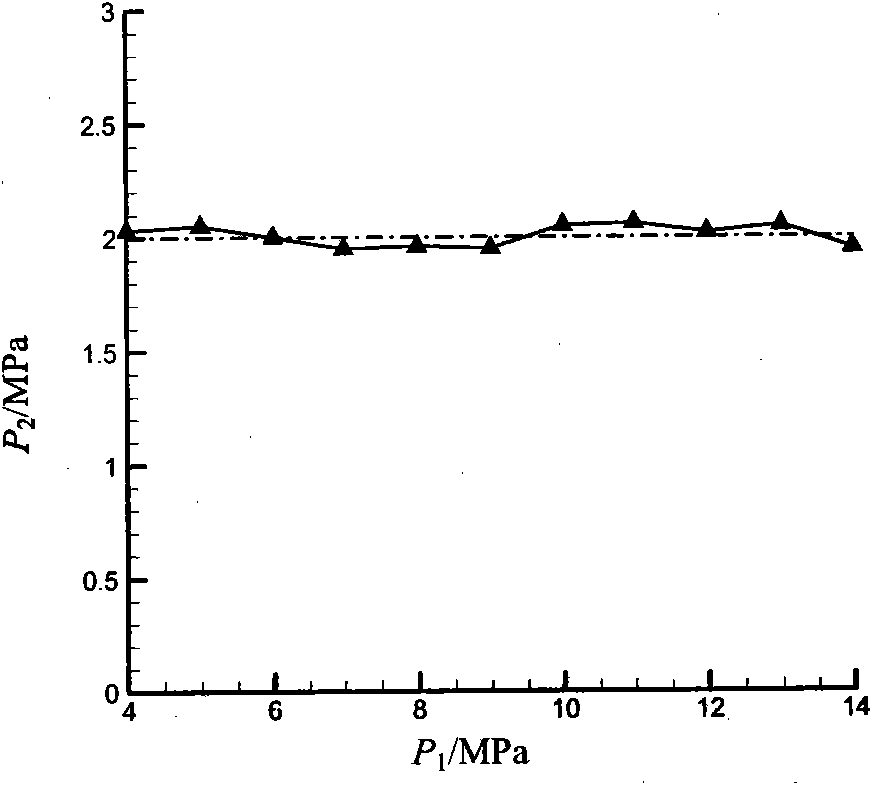

[0033] The principle of gas supply system is as follows: Figure 6 As shown, there is high-pressure air in the air storage tank 11, the high-pressure hand valve 16 is the main switch of the air source, the quantitative supply type electronically controlled pressure reducer 21 is arranged upstream of the pressure reducer 13 under test, and the pressure sensors 12 and 14 are used respectively To measure the inlet pressure P of the pressure reducer under test 1 and outlet pressure P 2 , the temperature sensor 22 is used to measure the air temperature, the flow meter 23 is used to measure the air flow, the throttling plate 24 is used to limit the air flow, and the solenoid valve 15 is a system switch. The inlet pressure P of the pressure reducer 13 under test 1 That is, the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com