Non-solvent polyurethane laminating adhesive with high initial stick force and preparation method and application thereof

A technology of solvent-free polyurethane and initial tack, applied in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as high initial tack and insufficient initial tack of solvent-free laminating adhesives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

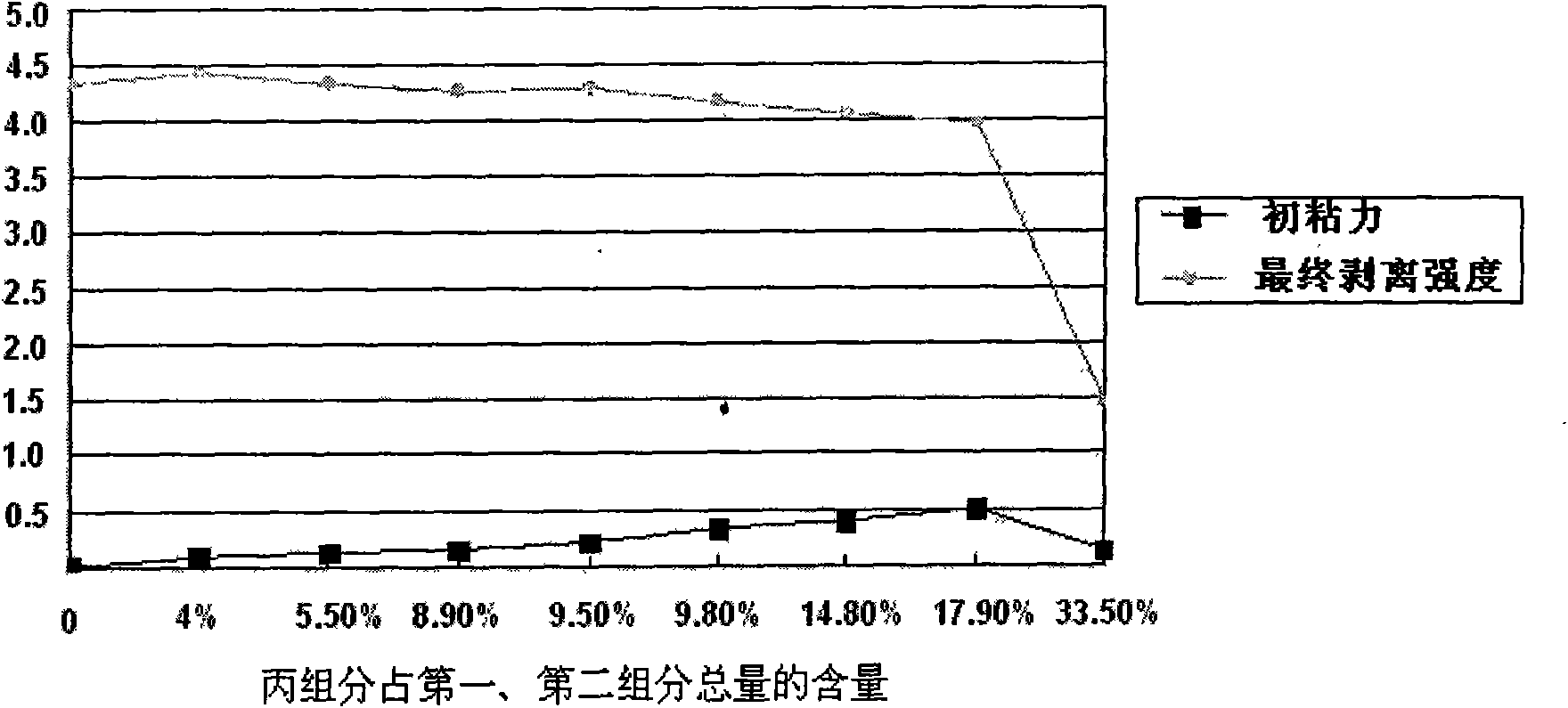

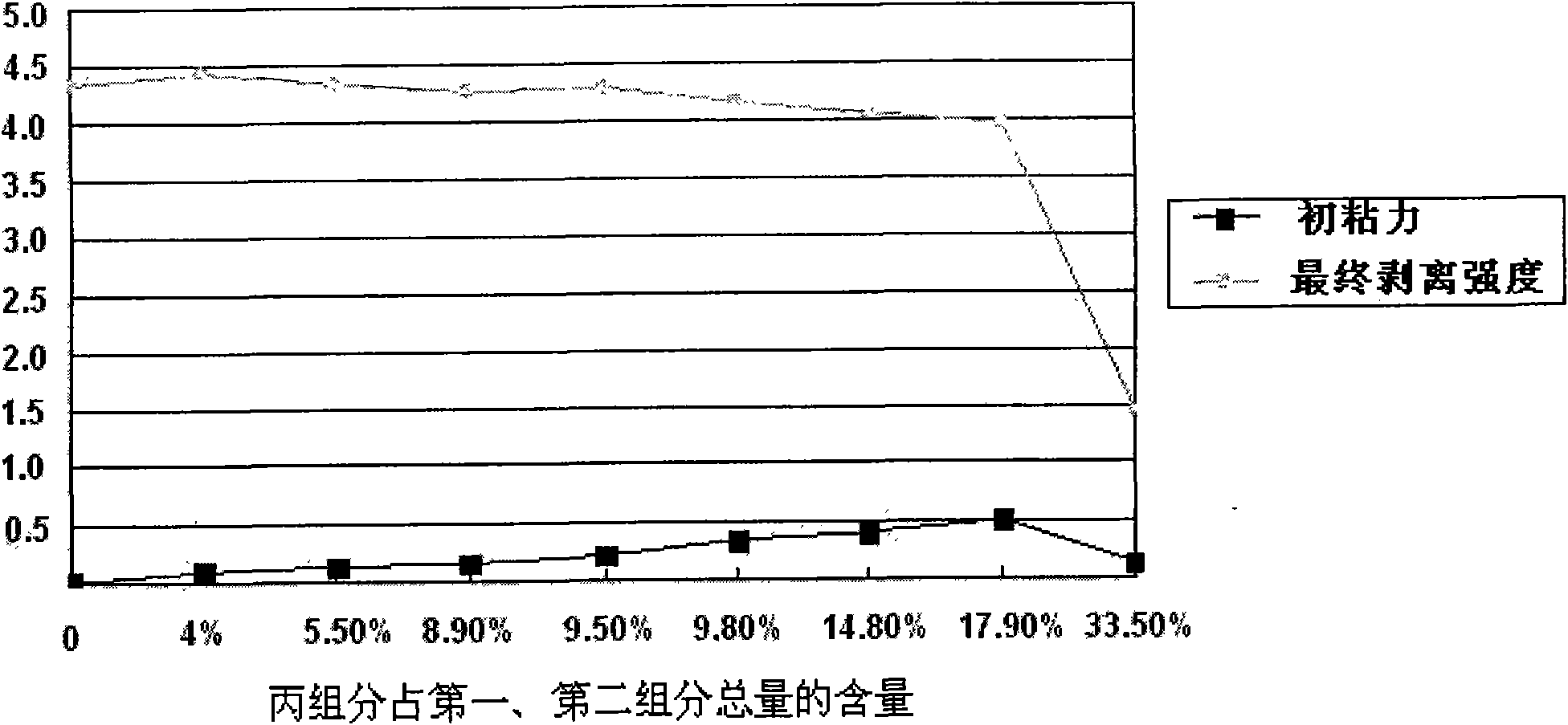

Image

Examples

Embodiment 1C-1

[0045] Synthesis of Example 1C-1

[0046] Put 60 parts of polyoxypropylene diol with a molecular weight of 2000, 13 parts of polyoxypropylene diol with a molecular weight of 400, and 2 parts of trimethylolpropane into a reaction vessel, and heat to 115°C for vacuum dehydration for 2 hours Add 110 parts of MDI and 14 parts of TDI after cooling down to below 60°C, heat up to 80°C for 2 hours, then cool down the temperature of the prepolymer below 60°C, add 140 parts of hydroxypropyl methacrylate, and heat up to 75°C for reaction After 2 hours, add 7 parts of photoinitiator 1173 to obtain component C, hereinafter referred to as C-1.

Embodiment 2C-2

[0047] Synthesis of Example 2C-2

[0048] Add 8 parts of photoinitiator 1173 to 100 parts of 1,3-butanediol diacrylate and 100 parts of hydroxyethyl methacrylate, and mix well to obtain component C, hereinafter referred to as C-2.

Embodiment 3A-0

[0049] Synthesis of Example 3A-0

[0050] Put 60 parts of polyoxypropylene diol with a molecular weight of 2000, 10 parts of castor oil-modified trihydric alcohol with a molecular weight of 900, and 1.5 parts of trimethylolpropane into a reaction vessel and heat to 115°C Vacuum dehydration for 2 hours, lower the temperature to below 60°C, add 90 parts of MDI, and raise the temperature to 80°C for 2 hours to react the prepolymer as the first component of the reaction, hereinafter referred to as A-0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com