Cutting assembly of wafer line cutting machine

A wire cutting machine, silicon wafer technology, applied in grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of increased swing, large surface roughness and thickness errors of slices, frequent shutdowns, etc., to prevent Axial displacement and radial runout, improve cutting efficiency, ensure the effect of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

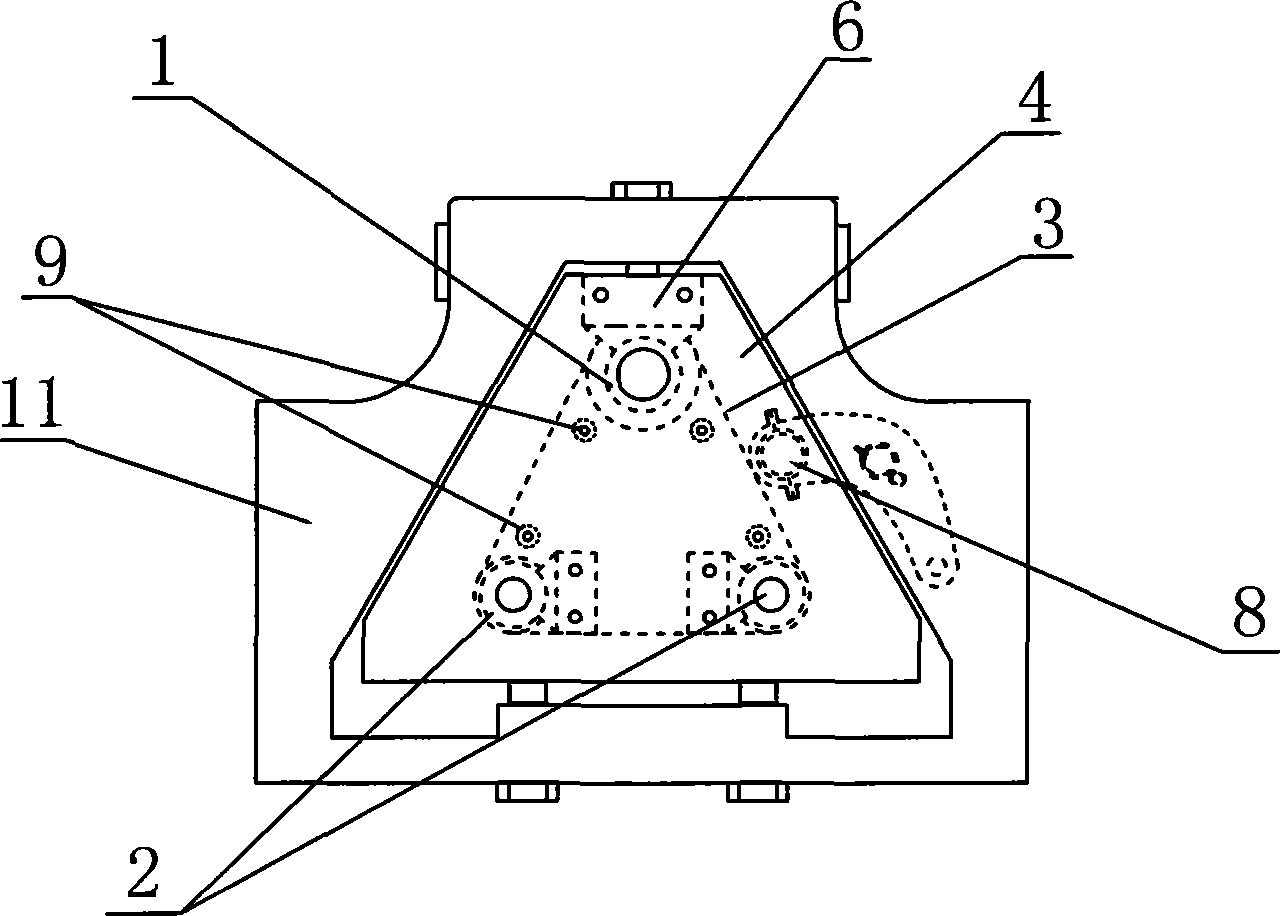

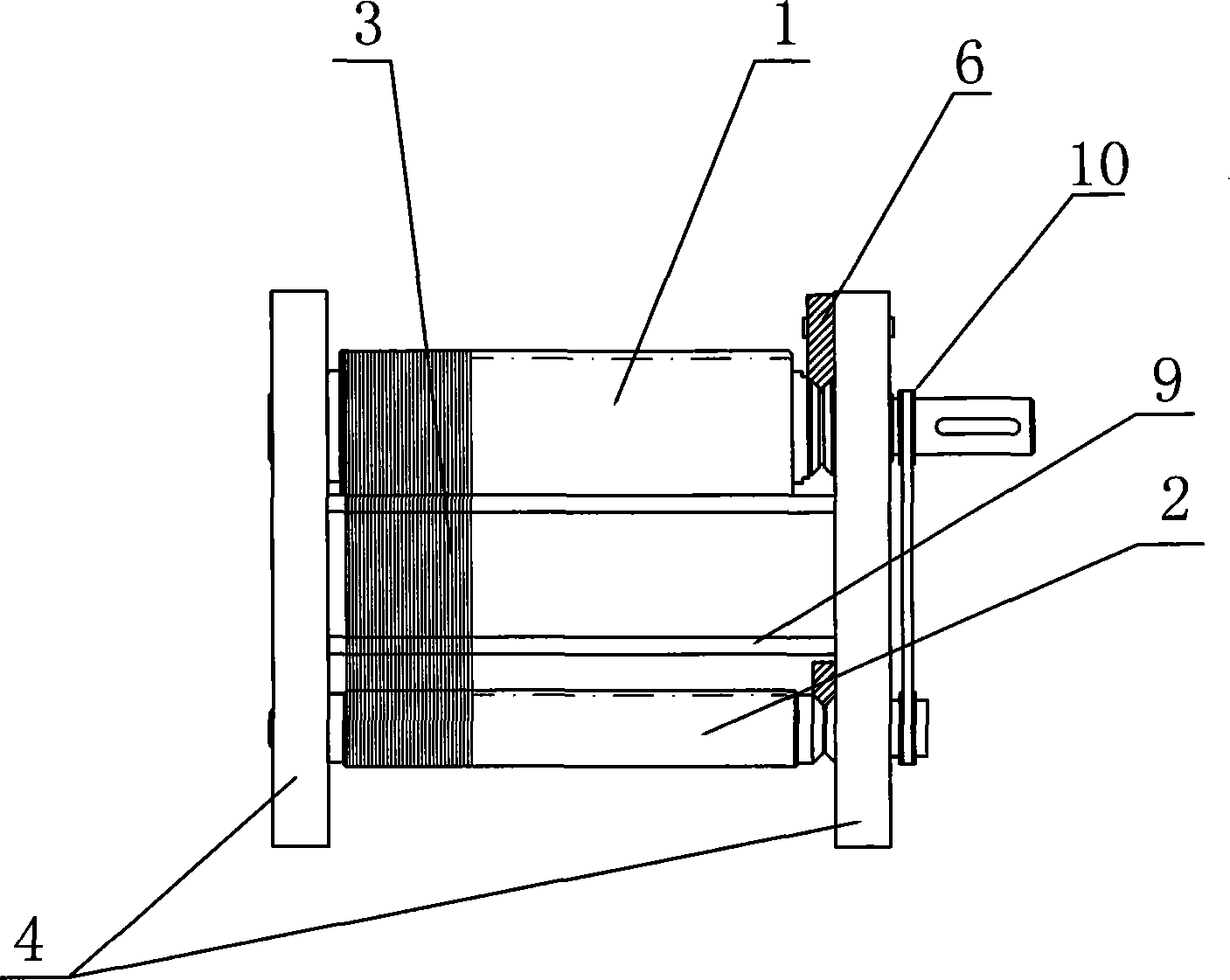

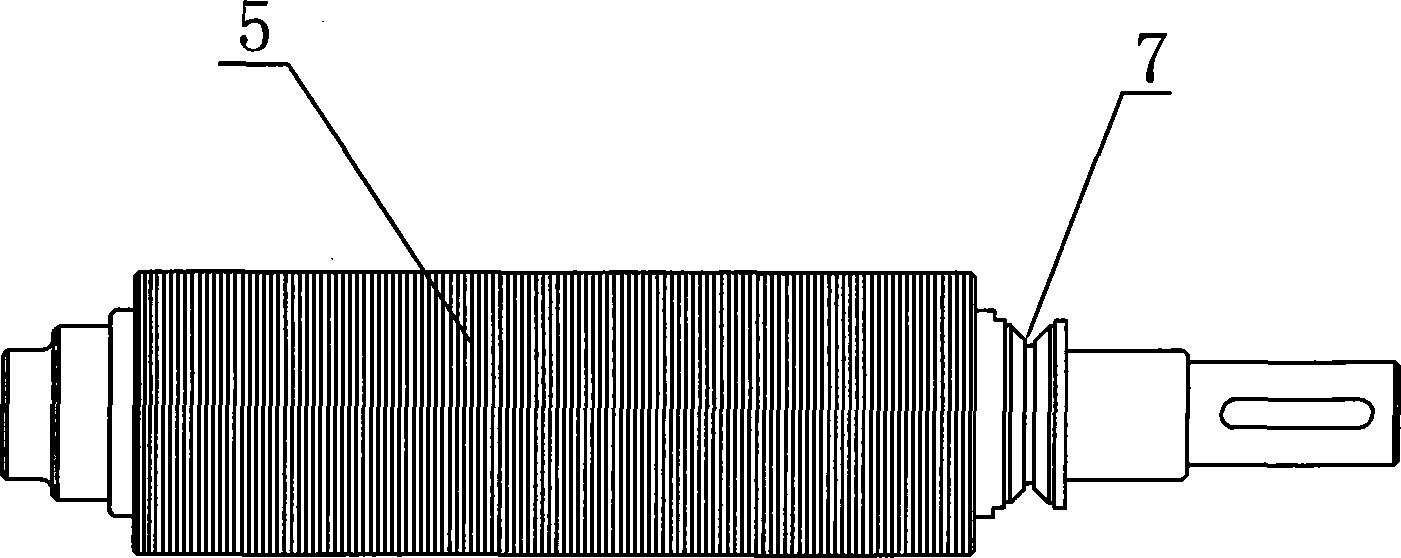

[0018] As shown in the figure, the cutting assembly of the silicon wafer wire cutting machine is mainly composed of the driving roller 1, the driven roller 2, the end plate 4 and the cutting line 3, and the driving roller 1 and the driven roller 2 are formed by the end plate 4 support, the circumference of the driving roller 1 and the driven roller 2 are respectively provided with annular wire grooves 5, and each wire groove is independent of each other and perpendicular to the axis of the rollers. The number of wire grooves on the driving roller 1 and the driven roller 2 is equal, and the distance between any two adjacent wire grooves 5 is equal. According to different specifications, the groove width of the wire groove 5 is 0.09-0.16mm, generally 0.13mm; the groove depth is 0.15-0.25mm, generally 0.2mm; the distance between two adjacent wire grooves 5 is 0.15-0.25mm , generally 0.15mm. The cutting line 3 is wound in the wire groove 5 corresponding to the position on the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com