Solid preparation of clopidogrel free alkali and preparation process thereof

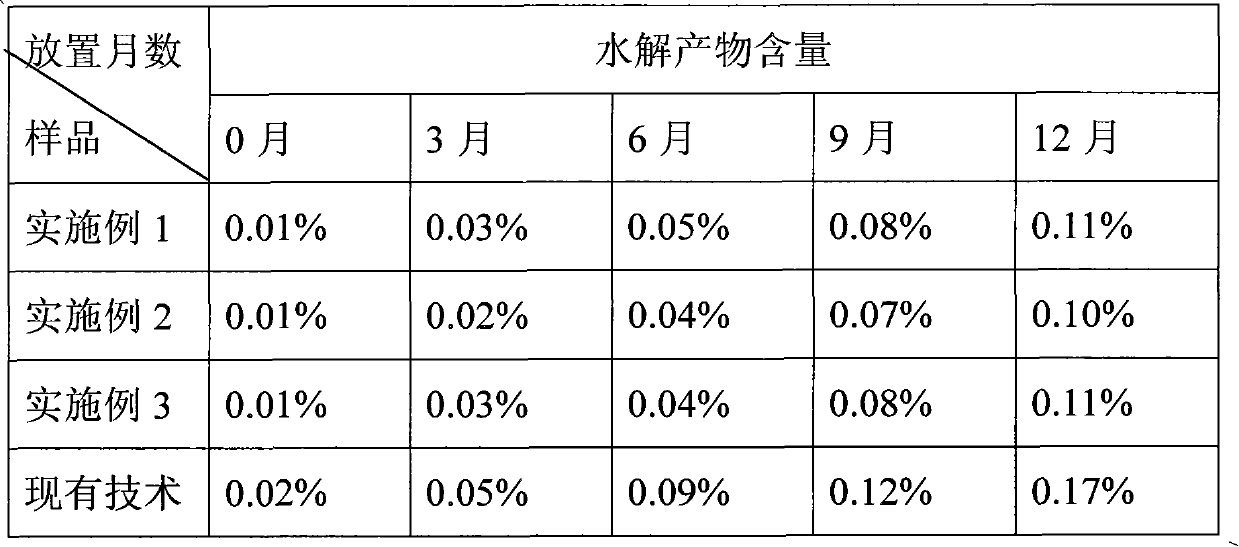

A technology of clopidogrel free base and solid preparation, applied in the field of solid preparation of clopidogrel free base and its preparation, to achieve the effect of improving safety, stability and effective therapeutic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The preparation method of the solid preparation of the above-mentioned clopidogrel free base, the method is prepared by wet granulation, and the specific steps are as follows:

[0014] 1) Mix anhydrous lactose, microcrystalline cellulose, mannitol, and hydroxypropyl cellulose evenly, add clopidogrel free alkali solution for wet granulation, fluidize boiling drying, and sieve the granules through a high-speed crushing and sizing machine with a size of 1.0mm grain.

[0015] 2) Mix the granules obtained in operation 1) with part of the pregelatinized starch, fumed silicon dioxide, and magnesium stearate, and then make a solid preparation through a suitable method.

[0016] In the above operation 1), in order to meet the uniformity of clopidogrel free base, fully stirring and cutting in a high-speed wet granulator is adopted. In order to meet the uniformity of particle size, use a high-speed crushing and sizing machine with a 1.0mm sieve for sizing.

[0017] In the above-...

Embodiment 1

[0019] Tablet prescription with unit tablet weight 0.500g, clopidogrel labeled content 75mg / tablet and wet granulation preparation process

[0020] prescription

quantity

content%

Clopidogrel free base

75g

15%

120g

24%

microcrystalline cellulose

200g

40%

[0021] prescription

quantity

content%

20g

4%

20g

4%

partially pregelatinized starch

50g

10%

10g

2%

5g

1%

Total

500g

100%

[0022] 1) Mix 120g of anhydrous lactose, 200g of microcrystalline cellulose, 20g of mannitol, and 20g of hydroxypropyl cellulose, and add clopidogrel free base (75g) solution for wet granulation, fluidized boiling drying, and granulation by high-speed crushing Granulator 1.0mm sieve for granulation.

[0023] 2) Mix 343g of th...

Embodiment 2

[0025] Tablet prescription with unit tablet weight 0.420g, clopidogrel labeled content 75mg / tablet and wet granulation preparation process

[0026] prescription

quantity

content%

Clopidogrel free base

75g

17.9%

anhydrous lactose

123g

29.3%

140g

33.3%

15g

3.6%

15g

3.6%

partially pregelatinized starch

40g

9.5%

8g

1.9%

Magnesium stearate

4g

0.9%

Total

420g

100%

[0027] 1) Mix 123g of anhydrous lactose, 140g of microcrystalline cellulose, 15g of mannitol, and 15g of hydroxypropyl cellulose, add clopidogrel free base (75g) solution for wet granulation, fluidize boiling drying, and granulate through high-speed pulverization Granulator 1.0mm sieve for granulation.

[0028] 2) Mix 374g of the granules obtained in operation 1) with 40g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com