Silicon-on-insulator lateral insulated gate bipolar transistor and process manufacturing method

A technology of silicon-on-insulator and bipolar transistors, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of silicon-eating, severe, and inability to accurately control the depth and concentration distribution of N-type doping buffers, etc. problem, to achieve the effect of increasing the lateral breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

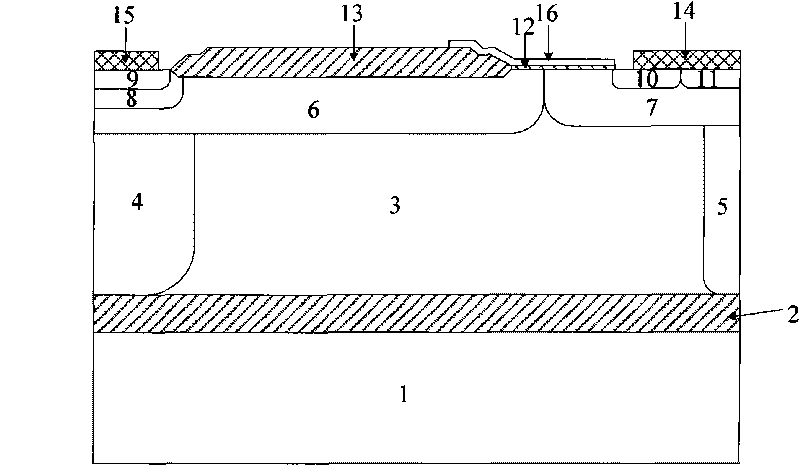

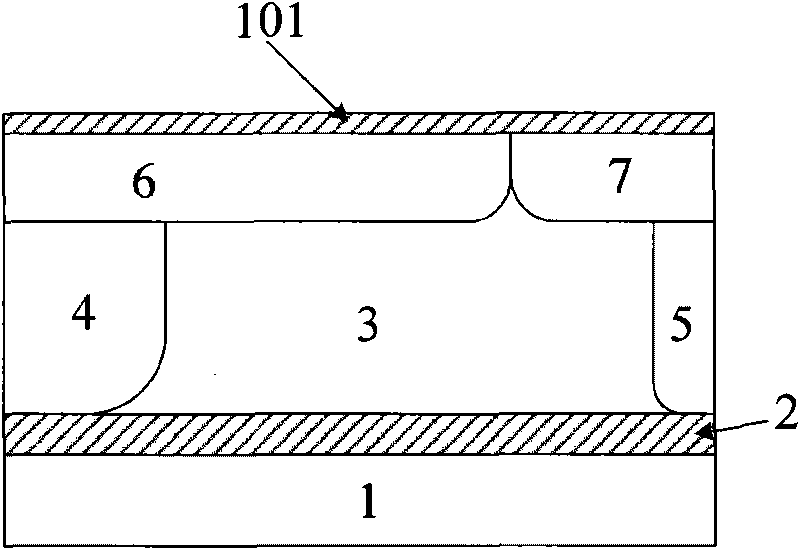

[0015] refer to figure 1 , a silicon-on-insulator lateral insulated gate bipolar transistor, comprising: a P-type doped semiconductor substrate 1, a buried oxide layer 2 is arranged on the P-type doped semiconductor substrate 1, and a P-type The doped epitaxial layer 3 is provided with an N-type doped deep well region 4 on the left side of the P-type doped epitaxial layer 3, and a P-type doped deep well region 5 is provided on the right side of the P-type doped epitaxial layer 3, An N-type doped drift region 6 is provided above the N-type doped deep well region 4 and part of the P-type doped epitaxial layer 3, and above the P-type doped deep well region 5 and part of the P-type doped epitaxial layer 3 A P-type doped semiconductor region 7 is provided. In the N-type doped drift region 6, an N-type doped buffer area 8 is arranged on the left side, and a P-type doped anode contact region 9 is arranged in the N-type doped buffer area 8, and in the P-type doped semiconductor regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com