Natural-draught brine cooling tower

A brine cooling and natural ventilation technology, applied in water shower coolers, sustainable manufacturing/processing, heat exchange equipment, etc., can solve problems such as high back pressure, lack of water resources, and increased operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

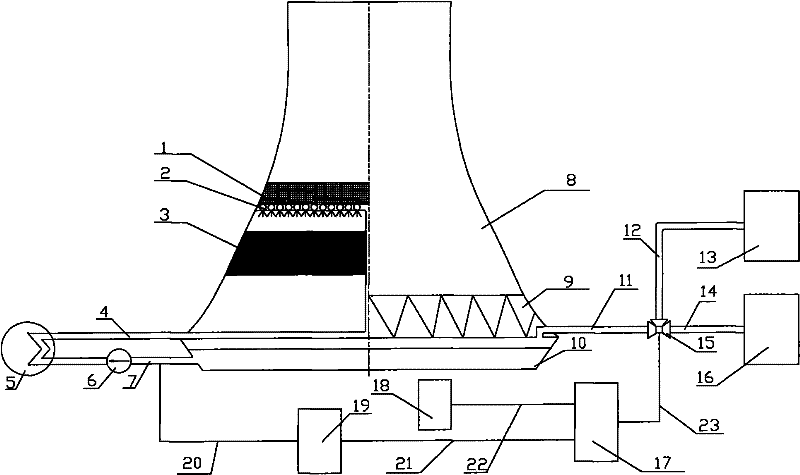

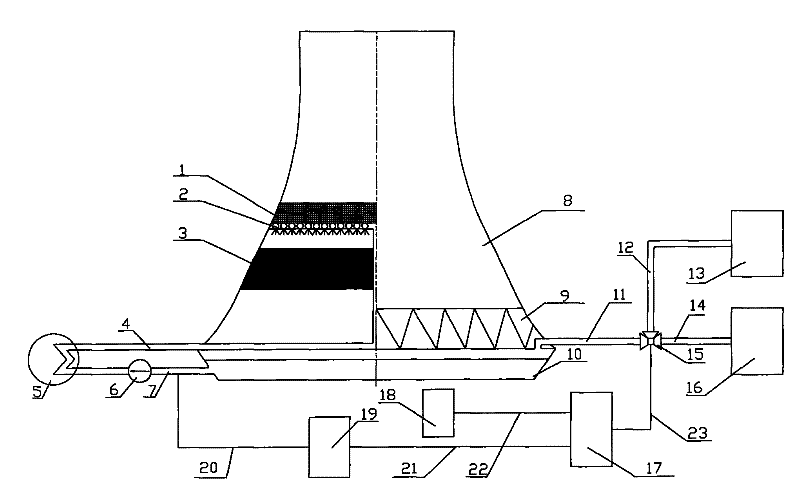

[0011] Such as figure 1 As shown, the natural ventilation brine cooling tower includes water collector 1, water distribution device 2, packing area 3, brine inlet pipe 4, waste heat source 5, circulating brine pump 6, brine outlet pipe 7, tower tube 8, herringbone Pillar 9, sump 10, main water supply pipe 11, tap water supply pipe 12, tap water storage tank 13, concentrated brine supply pipe 14, three-way valve 15, concentrated brine storage tank 16, brine temperature concentration controller 17, air temperature and humidity detector 18. Brine temperature and concentration detector 19, brine sampling tube 20, brine temperature and concentration signal line 21, air temperature and humidity signal line 22 and general control signal line 23; The water eliminator 1, the water distribution device 2 and the packing area 3 are arranged in sequence from the bottom, and a sump 10 is arranged under the tower tube 8 and the herringbone pillar 9; One end of the waste heat source 5 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com