Jean laser singeing machine

A denim and singeing machine technology, applied in textiles and papermaking, fabric surface trimming, etc., can solve problems such as low energy utilization, environmental pollution, singeing marks, etc., and achieve high energy utilization, safe operation, and air pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

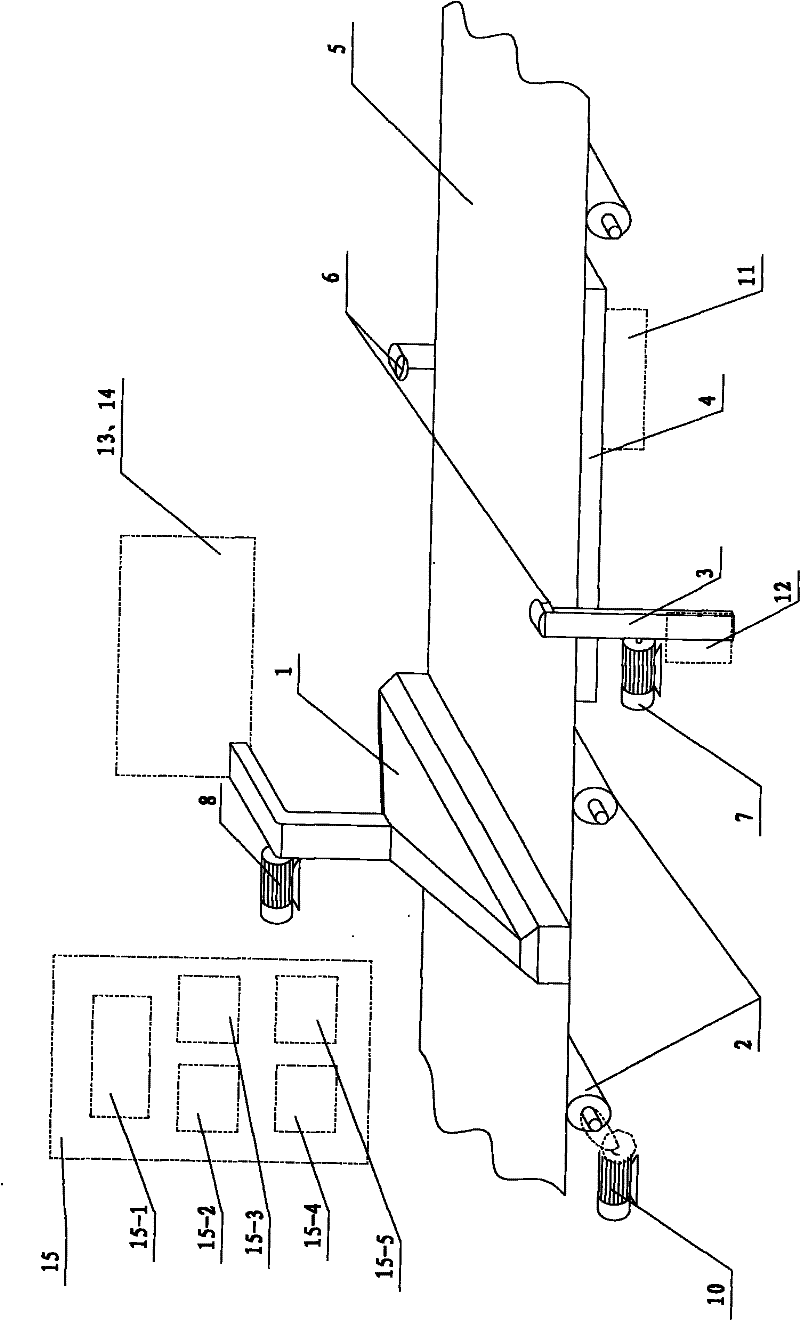

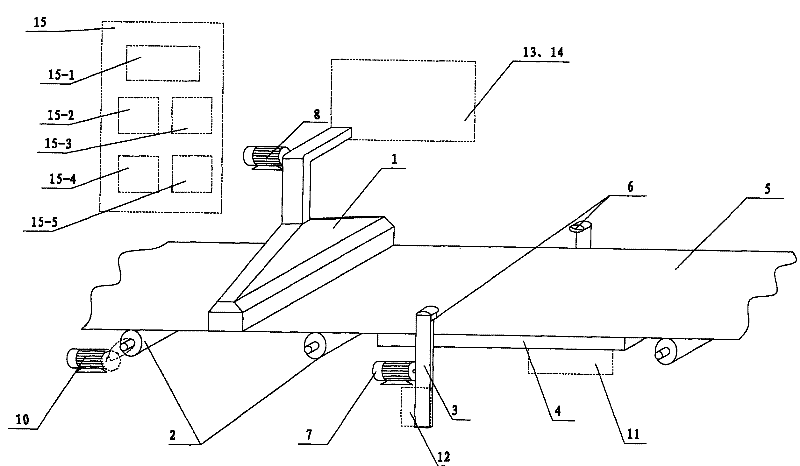

[0009] refer to figure 1 , the denim laser singeing machine of this embodiment includes a cloth feeding unit, a raising unit, a laser singeing unit, a fluff collecting unit, and a control unit; The fluffing unit is composed of an electrostatic generating plate 4 and an electrostatic generator 11; the laser singeing unit is composed of a laser generating head 6, a height adjustment stepping motor 7, a support guide plate 3 and a laser generator 12; the fluff collecting unit is composed of a fluff collector 1 , a hair suction motor 8, a fluff collection box 13 and a strength controller 14; the denim cloth surface 5 is placed above the cloth feeding support rod 2 and the static electricity generating plate 4, and the frequency conversion motor 10 is dragged to connect with the cloth feeding support rod 2 through a connector , the laser generating head 6 meshes with the rack on the support guide plate 3 through precision gears, the rack of the support guide plate 3 meshes with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com