Yellow fluorescent powder used by white light LED and preparation method thereof

A technology of phosphor powder and production method, which is applied in chemical instruments and methods, luminescent materials, and the use of gas discharge lamps, etc., to achieve the effects of simple steps and conditions, solving safety problems, and reducing requirements for high-temperature equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

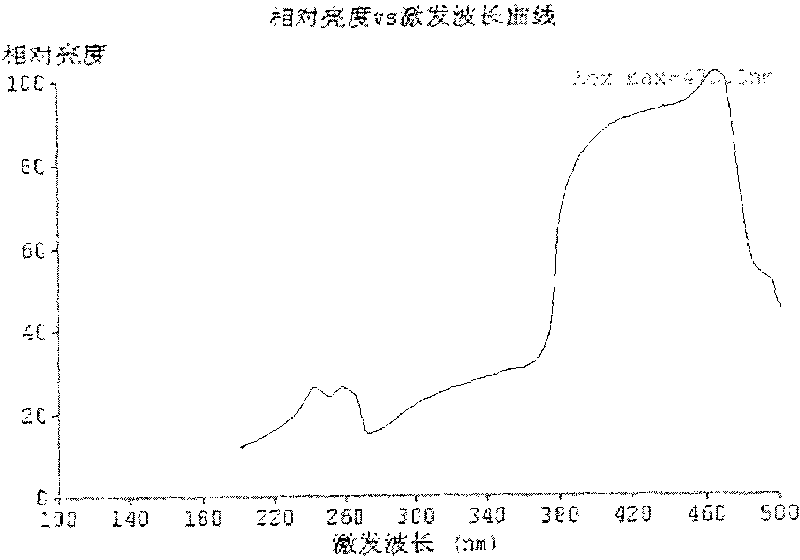

Image

Examples

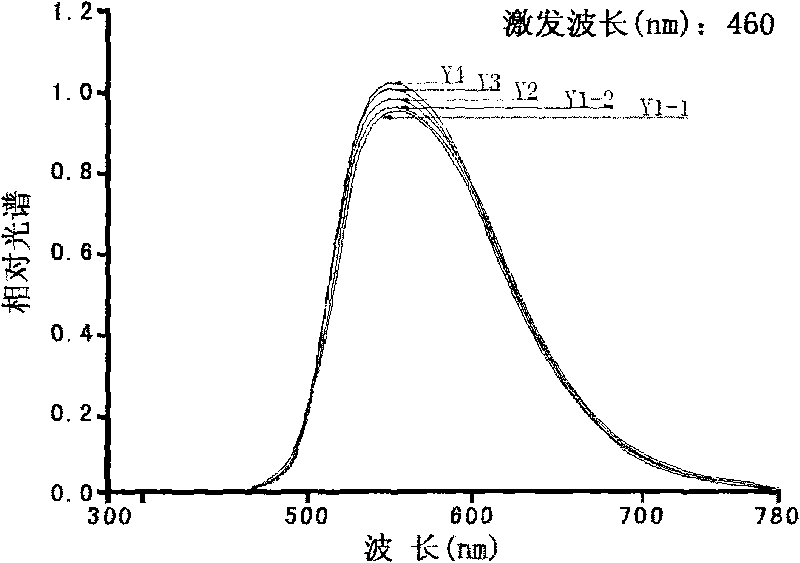

example 1

[0025] The composition of the phosphor is Y 2.94 Al 5 (O, F) 12 : 0.06Ce, the production method is as follows: Accurately weigh raw material Y 2 o 3 66.39g, Al 2 o 3 50.98g, CeO 2 2.01g, BaF 2 3.51g, the above raw materials are pre-mixed, then put into a 500ml ball mill jar and milled for 3 hours, the material is taken out and divided into 2 parts, and put into 2 alumina crucibles respectively, one crucible is not covered (sample number Y1 -1), the other crucible is covered (sample number Y1-2), and then put into an atmosphere box furnace for calcination at the same time, and kept at 1500°C for 4h, with a heating rate of about 10°C / min, and naturally cooled to At room temperature, NH is fed throughout the entire calcination process 3 Decomposition gas (75%H 2 +25%N 2 ). After cooling, the bulk powder is taken out, mechanically crushed, ball milled until the average particle size reaches 8.0±0.5um, soaked in hot water at 80°C to remove impurities, then passed thro...

example 2

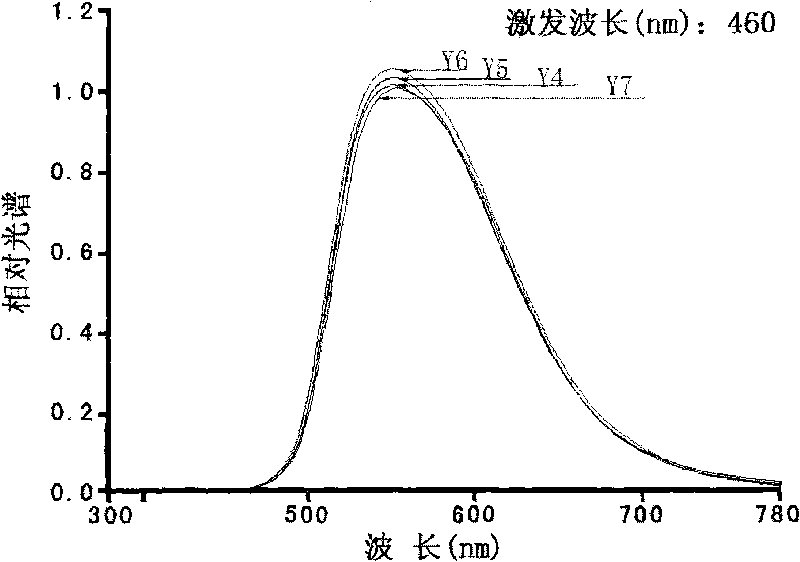

[0027] The composition of the phosphor is Y 2.94 Al 5 (O, F) 12 : 0.06Ce, the production method is as follows: Accurately weigh raw material Y 2 o 3 66.39g, Al2 o 3 50.98g, CeF 3 2.37g, BaF 2 3.51g, pre-mix the above raw materials, and then put them into a 500ml ball mill jar for ball milling for 3 hours, put the evenly mixed materials into an alumina crucible, cover the crucible without sealing it with ceramic glaze, and put it into an atmosphere box furnace Medium calcination, heat preservation at 1500°C for 4 hours, the heating rate is about 10°C / min, naturally cool to room temperature after the heat preservation is completed, and NH is introduced throughout the calcination process 3 Decomposition gas (75%H 2 +25%N 2 ). After cooling, the bulk powder is taken out, mechanically crushed, ball milled until the average particle size reaches 8.0±0.5um, soaked in hot water at 80°C to remove impurities, then passed through a 400-mesh wet sieve, centrifuged and dried to...

example 3

[0029] The composition of the phosphor is Y 2.94 Al 5 (O, F) 12 : 0.06Ce, the production method is as follows: Accurately weigh raw material Y 2 o 3 66.39g, Al 2 o 3 50.98g, CeF 3 2.37g, BaF 2 3.51g, pre-mix the above raw materials, and then put them into a 500ml ball mill jar for ball milling for 3 hours, put the evenly mixed materials into an alumina crucible, cover the crucible, fill the groove on the edge of the crucible with ceramic glaze, and then Put it in a vacuum drying oven for vacuum-filling nitrogen treatment. After the treatment, put it in an atmosphere box furnace for calcination, keep it at 1500°C for 4 hours, and the heating rate is about 10°C / min. After the heat preservation is completed, cool it naturally to room temperature. High-purity N is introduced throughout the calcination process 2 (purity>99.99%). After cooling, the bulk powder is taken out, mechanically crushed, ball milled until the average particle size reaches 8.0±0.5um, soaked in hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com