Hydrolysis resistant plastification polylactic acid composition and thin film thereof

A composition and technology of polylactic acid, applied in the field of plasticized polylactic acid composition and its film, can solve the problems of harmfulness to human health, increased melt viscosity, poor thermal stability, etc., achieve low price, excellent hydrolysis resistance, avoid The effect of the cross-linking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

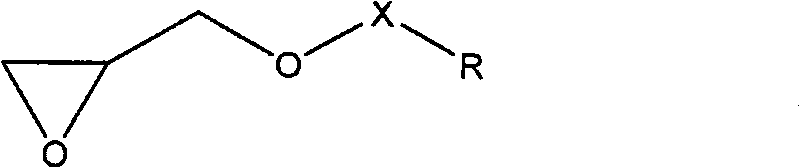

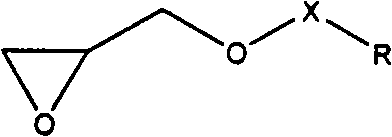

[0041] Polylactic acid resin (4032D, Nature works company, weight-average molecular weight 17-22w, optical activity 96%) and plasticizer (polyethylene glycol 6000, Sinopharm) were vacuum-dried at 80°C for more than 6 hours, and passed Screw extruder carries out melt blending extruding, when using extruder melt blending polylactic acid 70 weight parts and plasticizer 30 weight parts, add anti-hydrolysis stabilizer glycidyl methacrylate (molecular formula Commercially available) 1 weight part, the melt is granulated after cooling in a water tank, the temperature of the feeding section of the extruder is 170°C, the temperature of the second section is 190°C, and the remaining sections are 200°C, the speed of the extruder is 400rpm, and the electrostatic device is set at 9kv. A film was obtained by extension molding, and the thickness of the film was 300 μm. The molecular weight change before and after hydrolysis of the film was tested, and the results are shown in Table 1.

Embodiment 2

[0043] Polylactic acid resin (4032D, Nature works company, weight-average molecular weight 17-22w, optical activity 96%) and plasticizer (polyethylene glycol 6000, Sinopharm) were vacuum-dried at 80°C for more than 6 hours, and extruded Add glycidyl methacrylate (molecular formula commercially available) 3 parts by weight, the machine temperature and rotating speed are the same as in Example 1, and finally cast to obtain a film with a film thickness of 300 μm. The molecular weight change before and after hydrolysis of the film was tested, and the results are shown in Table 1.

Embodiment 3

[0045] Polylactic acid resin (4032D, Nature works company, weight-average molecular weight 17-22w, optical activity 96%) and plasticizer (polyethylene glycol 6000, Sinopharm) were vacuum-dried at 80°C for more than 6 hours, and extruded Glycidyl methacrylate (molecular formula Commercially available) 5 parts by weight, the machine temperature and rotating speed are the same as in Example 1, and finally cast to obtain a film with a film thickness of 300 μm. The molecular weight change before and after hydrolysis of the film was tested, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com