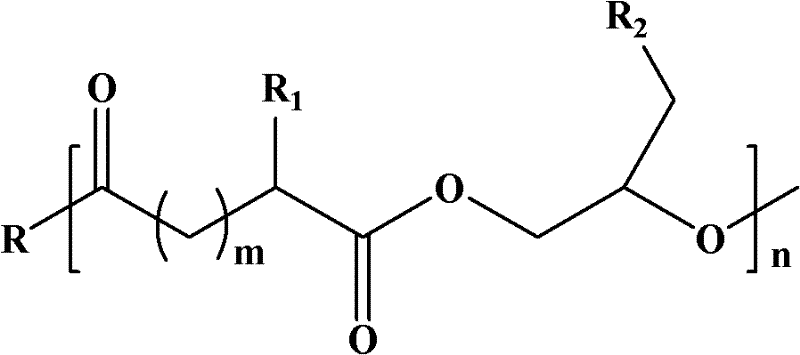

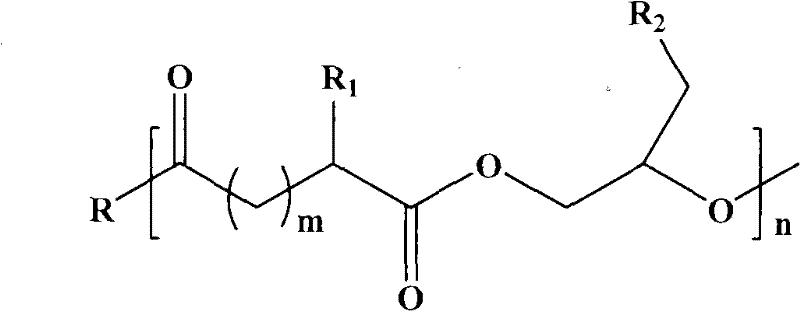

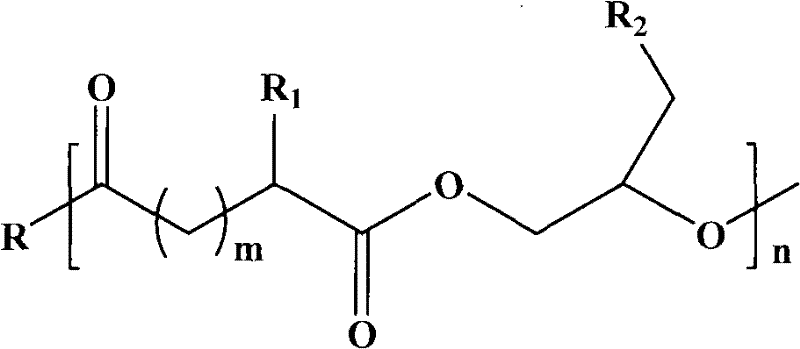

Functionalized polyester and preparation method thereof

A functionalized polyester technology, applied in the field of functionalized polyester and its preparation, can solve the problems of single response to external environmental stimuli and difficult copolymerization, and achieve the effects of good biocompatibility and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of functionalized polyester, comprising: under anhydrous conditions, a small molecule alcohol or a polymer initiator with a melting point lower than 120°C, stannous isooctanoate, and a molar ratio of 1:1 The functionalized epoxy compound and the functionalized anhydride are mixed to obtain a mixture;

[0047] heating and stirring the mixture at 100°C to 150°C for 34h to 38h, causing the mixture to undergo a polymerization reaction to obtain a polymer;

[0048] After diluting and filtering the polymer, the filtrate is taken, and then the filtrate is subjected to sedimentation, washing and drying operations to finally obtain the functionalized polyester.

[0049] According to the present invention, first under anhydrous conditions, the functionalized epoxy compound and the functionalized acid anhydride that the small molecular alcohol or the melting point is lower than 120 ℃ polymer initiator, stannous isooctanoate,...

Embodiment 1

[0053] Example 1: Preparation of poly(2-((2-methoxyethoxy)methyl)oxirane-co-glutaric anhydride) of different chain lengths

[0054] Under anhydrous conditions, weigh 7 parts of 2-((2-methoxyethoxy) methyl) oxirane and 4.32 g of glutaric anhydride with a mass of 5.0 g, and put them into 7 dry In the reaction flask, add 0.258g, 0.052g, 0.026g, 0.013g, 0.009g, 0.006g, 0.005g aluminum triisopropoxide respectively, and react at 120°C for 36 hours under bulk conditions and stirring with a stir bar. After the reaction, use three Dilute the reaction system with methyl chloride, filter off the insoluble matter, settle in a mixed solvent of ether, n-hexane and ethyl acetate, wherein the volume ratio of ether, n-hexane and ethyl acetate is 1:8:1, wash the product with n-hexane , and dried under vacuum at 25°C for 24h to obtain poly(2-((2-methoxyethoxy)methyl)oxirane-co-glutaric anhydride) with different chain lengths. The resulting functionalized polyester is shown in Table 1.

[0055]...

Embodiment 2

[0058] Embodiment 2: Preparation of poly(2-((2-(2-methoxyethoxy)ethoxy)methyl)oxirane-co-glutaric anhydride):

[0059] Under anhydrous conditions, weigh 6.67g of 2-((2-(2-methoxyethoxy)ethoxy)methyl)oxirane and 4.32g of glutaric anhydride, put Add 0.026g of aluminum triisopropoxide to the dry reaction bottle, and react for 36h under the bulk condition of 120°C and stirring with a stirring bar. Settled in a mixed solvent of ethyl acetate, wherein the volume ratio of ether, n-hexane and ethyl acetate was 1:8:1, washed the product with n-hexane, dried in vacuum at 25°C for 24h, and obtained poly(2-((2- (2-Methoxyethoxy)ethoxy)methyl)oxirane-co-glutaric anhydride). Depend on 1 The degree of polymerization of the product determined by H NMR was 100, and the number average molecular weight was 29060. Reaction yield: 86.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com