Bi2-xAg3xS3 thermoelectric material and preparation method thereof

A thermoelectric material and a general formula technology, applied in the field of ion sintering process, Bi2-xAg3xS3 thermoelectric material and its preparation, to achieve the effect of controllable particle size, short time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

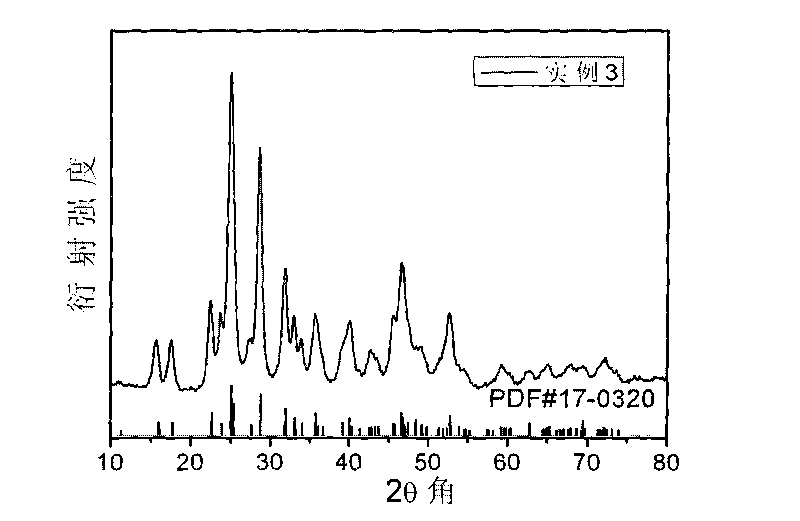

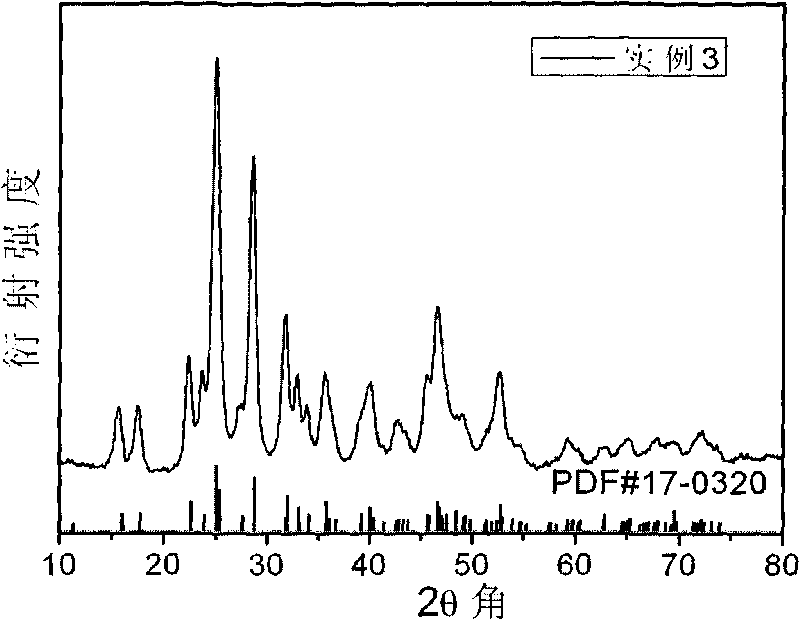

[0018] Bi was first prepared by mechanical alloying method 2-x Ag 3x S 3 Nano powder, the method is to use high-purity Bi, Ag and S elemental powder according to the general chemical formula Bi 2-x Ag 3x S 3 Proportioning, put them together in a planetary high-energy ball mill for mechanical alloying under the protection of an inert gas (Ar), dry-mill the synthetic compound, then wet-mill, and dry to obtain Ag-doped Bi 2 S 3 Nano-powder; powder discharge plasma sintering to obtain bulk material.

[0019] The test conditions are as follows: the value range of x is x=0.001~1.0; dry grinding under the protection of inert gas (At gas) for 1~20h, the speed is 100~600rpm; wet grinding under the atmosphere of absolute ethanol for 0.25~5h, the speed is 100 ~400rpm; SPS sintering temperature 200~600℃, mold diameter 10~30mm, pressure 20~60MPa.

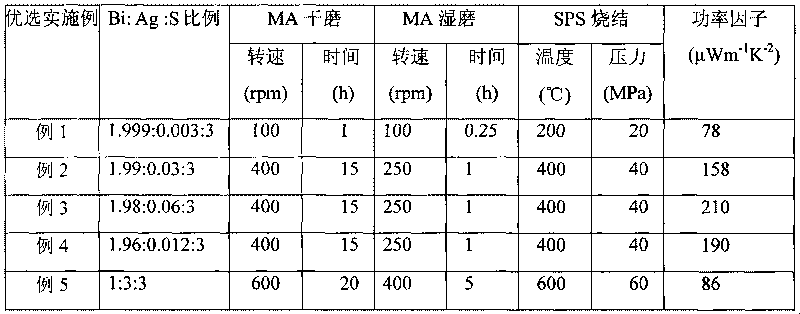

[0020] Table 1 has provided the present invention (Bi 2-x Ag 3x S 3 ) of several preferred embodiments:

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com