Azotized carbon nano cones and method for preparing same

A nano-cone and nano-technology, applied in the direction of nitrogen and non-metallic compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

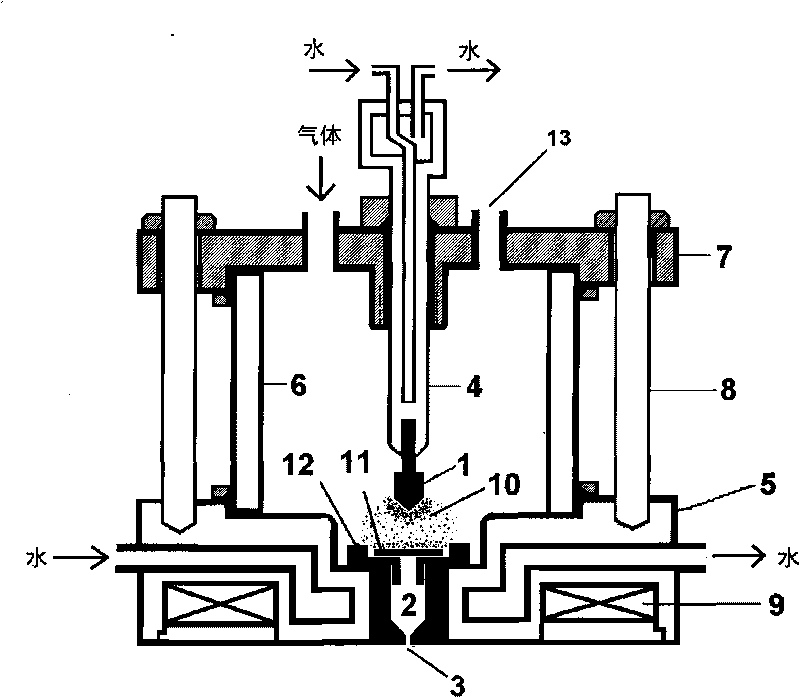

[0023] A nitrided nanocone comprising β-C 3 N 4 , graphite phase C 3 N 4 and CN x ; Among them, x is a positive integer or decimal. Its preparation method comprises the following steps:

[0024] (1) First, a layer of 10-100 nanometer intermediate layer is deposited on the surface of a smooth substrate material in a vacuum chamber, and the process of depositing the intermediate layer adopts a pulsed laser ablation method;

[0025] The material of the intermediate layer is selected from one of cobalt / nickel, cobalt / iron, cobalt, nickel or iron,

[0026] (2) Next, heating the substrate to 280-300 degrees Celsius to allow it to cool naturally;

[0027] (3) Again, the substrate obtained in step (2) is placed on a graphite base in a vacuum chamber, an atomic beam source is arranged above the graphite base, and methane with a volume ratio of 1 / 20 to 1 / 150 / Nitrogen mixed gas is passed into the atomic beam source, and when the internal pressure of the atomic beam source reaches...

Embodiment 1

[0035] The parameters of the preparation process are as follows:

[0036] Anode-cathode spacing: 0.6 cm, cathode lead hole size: length 0.12 cm, diameter 0.2 cm, vacuum chamber background vacuum: 10-7 Torr, atomic beam source pressure: 30 Torr, vacuum chamber pressure: 3 Torr, discharge current: 150 mA, discharge voltage: 150 V, Co / Ni transition layer thickness: 100 nm, methane / nitrogen volume ratio: 1 / 50, deposition rate: 0.03 μm / min.

[0037] The composition and structure index of the synthesized carbon nitride nanocone:

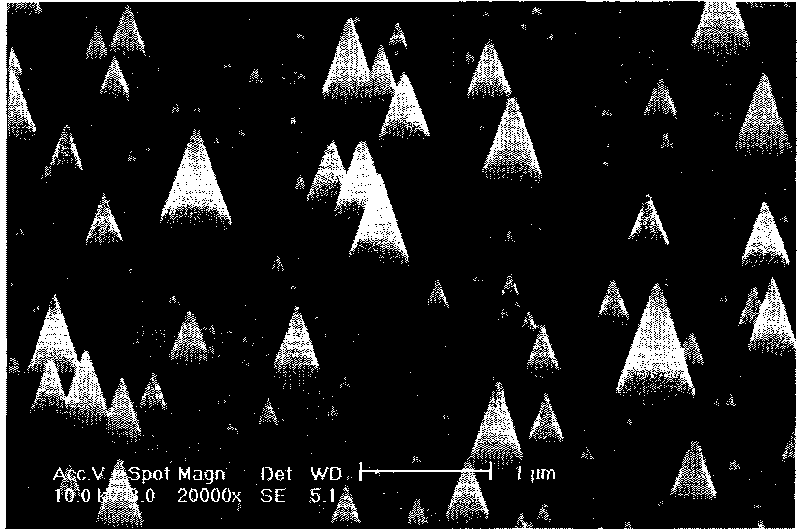

[0038] The thin film is composed of nanoscale cone tip arrays perpendicular to the substrate;

[0039] The average bottom diameter is 500 nm, and the aspect ratio is 2:1;

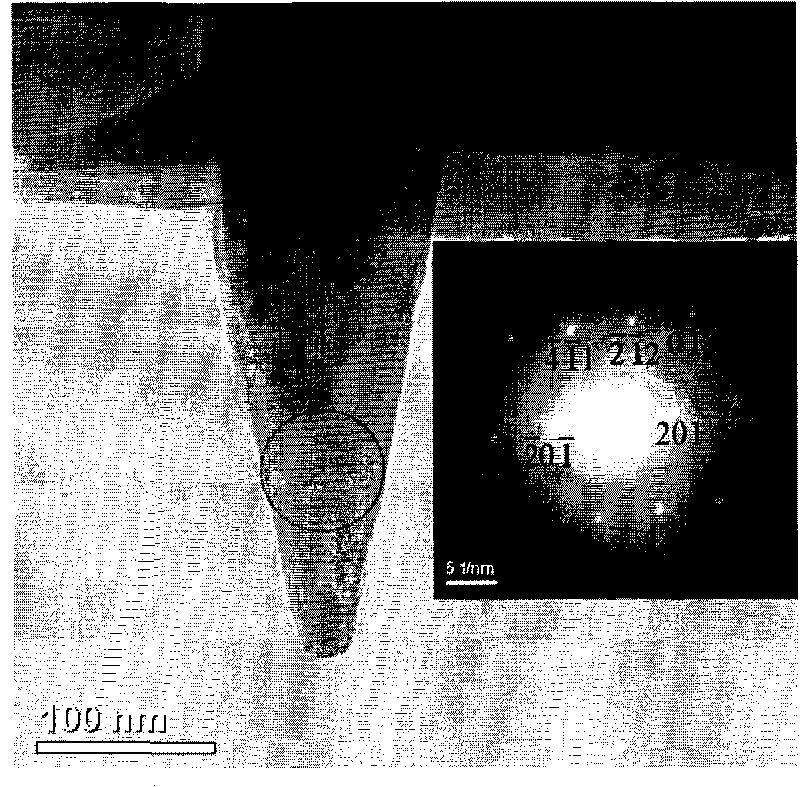

[0040] β-C in nanocones 3 N 4 and graphite phase C 3 N 4 The composition ratio is 3:1;

[0041] The content of graphite and amorphous carbon in the cone is less than 5%.

Embodiment 2

[0043] The parameters of the preparation process are as follows:

[0044] Anode-cathode spacing: 0.6 cm, cathode lead hole size: length 0.12 cm, diameter 0.2 cm, vacuum chamber background vacuum: 10 -7 Torr, atomic beam source pressure: 30 Torr, vacuum chamber pressure: 3 Torr, discharge current: 150 mA, discharge voltage: 150 volts, Co / Ni transition layer thickness: 100 nm, methane / nitrogen volume ratio: 1 / 20, Deposition rate: 0.05 microns / min.

[0045] The composition and structure index of the synthesized carbon nitride nanocone:

[0046] The thin film is composed of nanoscale cone tip arrays perpendicular to the substrate;

[0047] The average bottom diameter is 100 nm, and the aspect ratio is 10:1;

[0048] β-C in nanocones 3 N 4 and graphite phase C 3 N 4 Composition ratio 1.5:1;

[0049] The composition of graphite and amorphous carbon in the cone is about 12%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com