Micro-electromechanical structure and manufacturing method thereof

A technology of micro-electromechanical structure and manufacturing method, which is applied in the direction of micro-structure technology, micro-structure devices, and manufacturing micro-structure devices, etc., can solve the problems of insufficient structural strength and the use of microphone backboards, and achieve fewer post-processing steps. The effect of high process precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiment of the present invention provides a microelectromechanical structure to increase the strength of the structure in the thickness direction, and provides a manufacturing method of the microelectromechanical structure, which can simply produce a high aspect ratio structure.

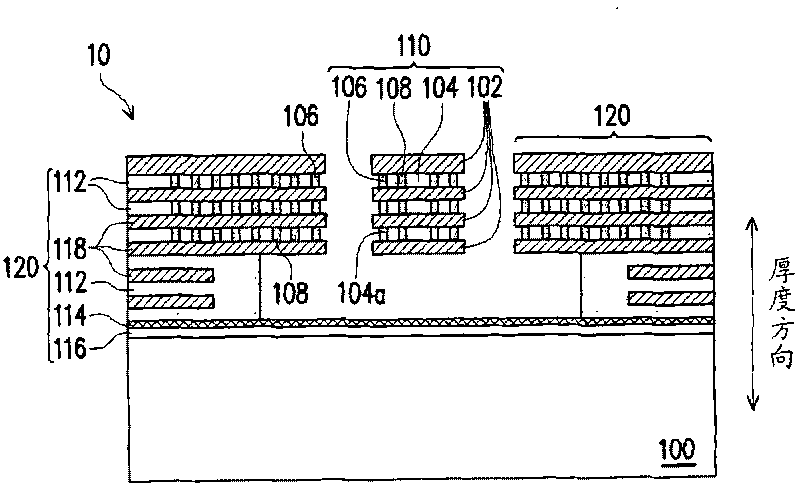

[0028] figure 1 It is a schematic cross-sectional view of a microelectromechanical structure according to an embodiment of the present invention.

[0029] Please refer to figure 1 The microelectromechanical structure 10 of this embodiment includes a substrate 100 and a suspended microstructure 110 on the substrate 100. in figure 1 Only one suspended microstructure 110 is shown in, but the invention is not limited to this. The aforementioned suspended microstructure 110 includes a metal layer 102, a dielectric layer 104, and an edge metal wall 106. The dielectric layer 104 is sandwiched between the metal layers 102, and the edge metal wall 106 is parallel to the thickness direction of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com