Intensified abrasive machining method for mechanical surface

A technology of grinding and surface strengthening, applied in the field of mechanical surface processing, can solve the problems of low efficiency, high labor intensity, poor processing ability, etc., and achieve the effect of prolonging fatigue life, improving surface hardness and improving surface roughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

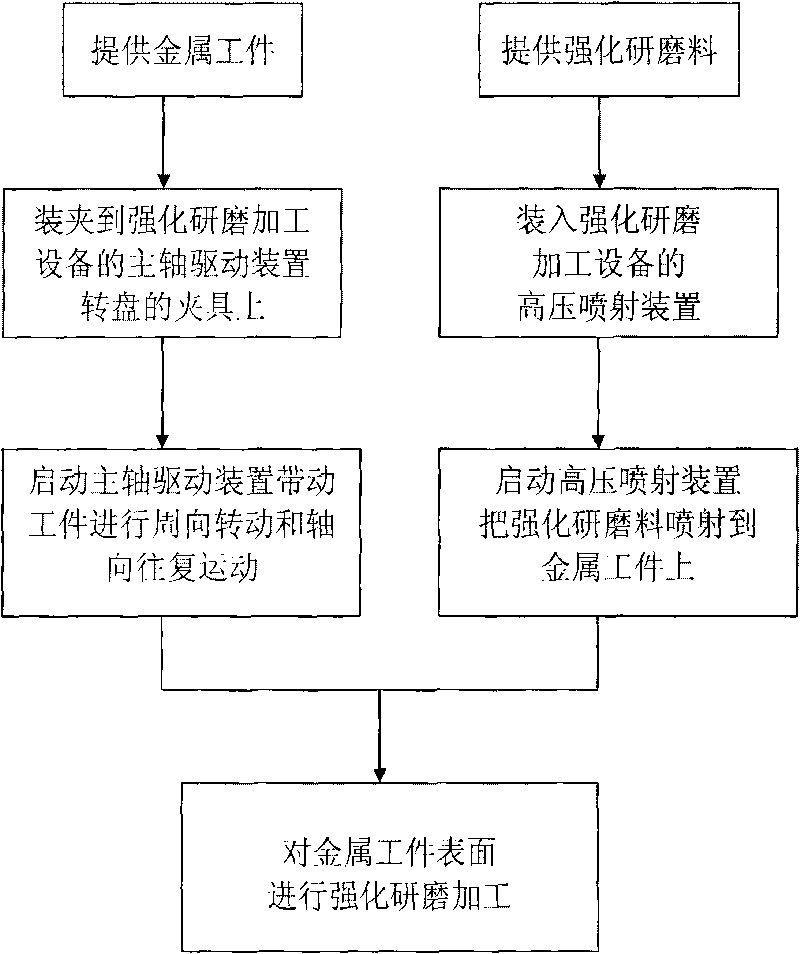

Method used

Image

Examples

Embodiment 1

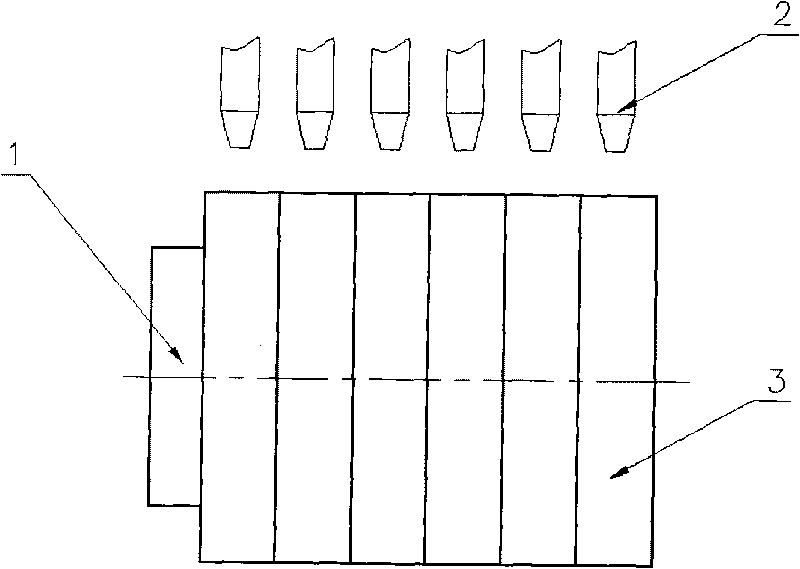

[0026] Such as figure 2 As shown, a method for intensified grinding of the mechanical surface, for the intensified grinding of the surface of the metal workpiece 3 of the revolving body, the end face of the workpiece 3 of the revolving body is placed on the axis of rotation of the rotating disk 1 of the spindle drive device, and the end surface of the workpiece 3 of the revolving body Closely strung in a row and its center is aligned with the center of the rotating disc rotation 1 coaxial, the enhanced abrasive consisting of 75% mixed steel balls, 20% enhanced liquid and 5% abrasive powder is loaded into the enhanced grinding process The high-pressure spraying device 2 of the equipment, on the one hand, uses the high-pressure spraying device 2 to spray the reinforced abrasive onto the processing surface of the metal workpiece 3 of the rotary body by means of high-pressure spraying; As the processing time increases, the collision and micro-cutting on the surface of the metal w...

Embodiment 2

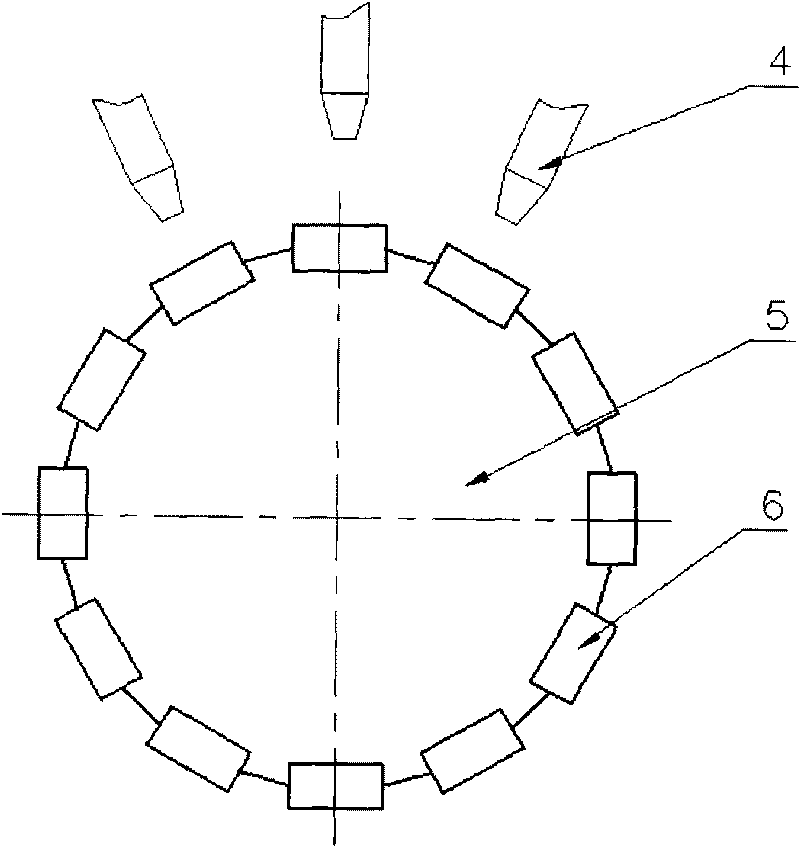

[0028] Such as image 3 As shown, a method for intensified grinding of mechanical surfaces, for intensified grinding of the surface 6 of a box-like metal workpiece, fixtures are installed on the outer circle of the rotating disk 5 of the spindle drive device in equal parts, and the surface to be intensified The ground box-like metal workpiece 6 is clamped to the fixture, and then the strengthened abrasive composed of 72% mixed steel balls, 18% strengthened liquid and 10% grinded powder is loaded into the high-pressure injection device of the strengthened grinding processing equipment 4. On the one hand, the high-pressure injection device 4 is used to spray the reinforced abrasive onto the processing surface of the box-like metal workpiece 6 by means of high-pressure injection; on the other hand, the spindle drive device drives the box-like metal workpiece 6 to produce circumferential motion and axial back and forth Reciprocating movement, with the increase of processing time, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com