High-strength and high-flexible acid electrode for ships

An acid electrode, high-strength technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problems of low weld strength and low-temperature impact toughness, low welding fume toxicity, and low transition efficiency. The effect of reducing manganese content, excellent comprehensive performance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

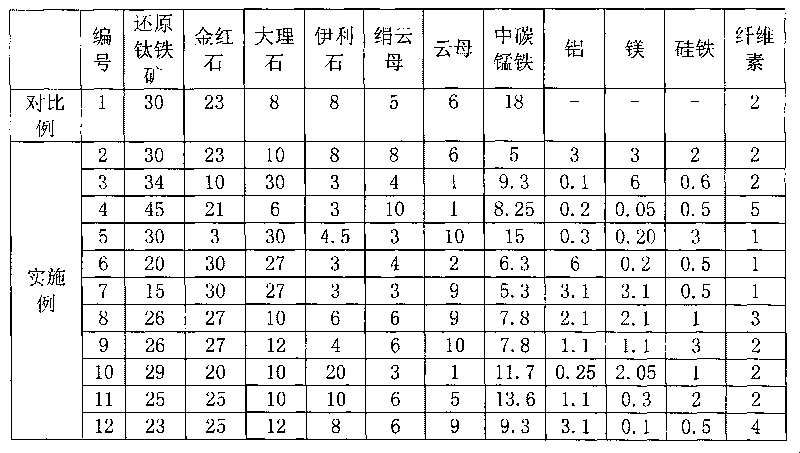

[0019] Referring to Table 1, the mass percent parameters of 12 kinds of coating components have been listed in Table 1, wherein there is 1 comparative example without adding aluminum, magnesium and ferrosilicon and 11 embodiments of electrode coating of the present invention, used The welding core is H08A, and the welding rod of the present invention is produced by conventional acid welding rod manufacturing process, wherein the aluminum and magnesium are aluminum powder and magnesium powder or aluminum-magnesium alloy, and the described ferrosilicon is No. 45 ferrosilicon. And the chemical composition and mechanical properties of the deposited metal of the comparative example and each embodiment electrode in Table 1 were tested. The results are shown in Table 2.

[0020] Table 1 Electrode coating composition (mass percentage)

[0021]

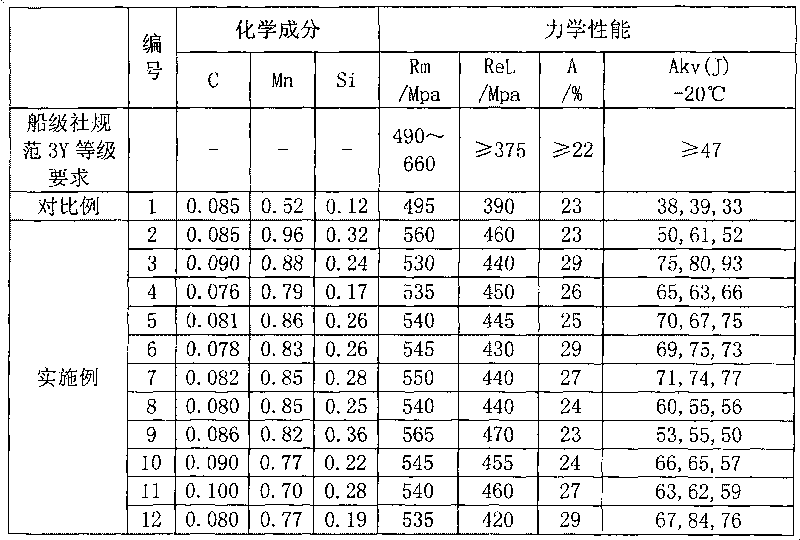

[0022] Table 2 Chemical composition and mechanical properties of deposited metal

[0023]

[0024] Referring to Table 2, it can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com