Method for eliminating incomplete penetration and weak root connection of friction stir welding joint

A friction stir, welding head technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as weak root connections, and achieve the effect of enhancing stability, simple assembly process, and simple welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

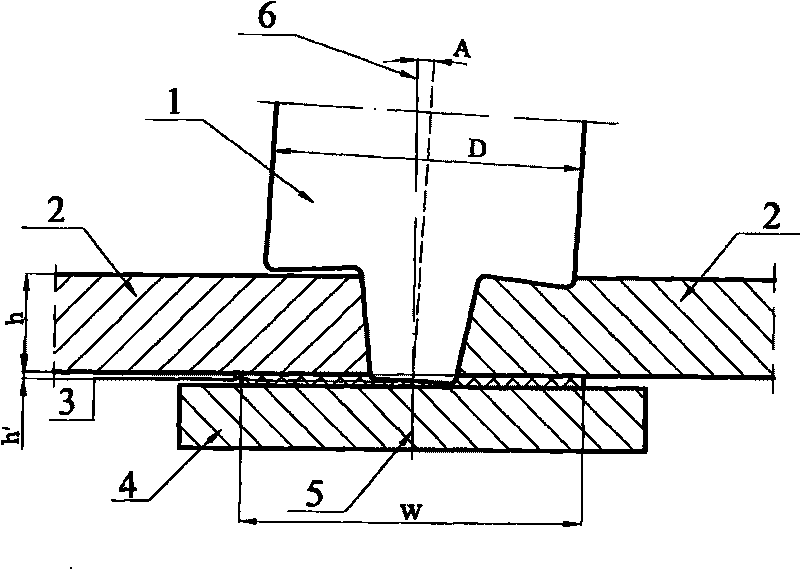

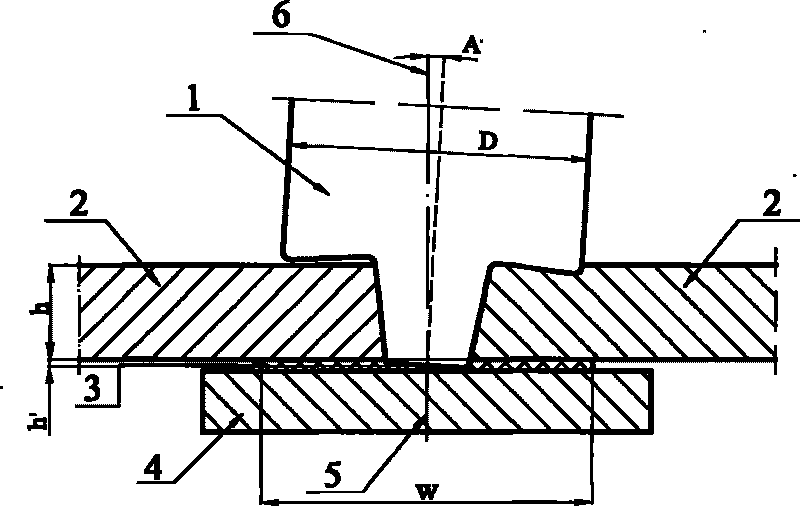

[0017] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0018] Accompanying drawing is the operation schematic diagram of the elimination method of friction stir welding joint incomplete penetration and root weak connection of the present invention, as shown in the embodiment of accompanying drawing, in the middle of workpiece 2 to be welded and back rigid backing plate 4, a layer and workpiece are added. For the gasket 3 of the same material, the stirring tool 1 completely penetrates the welding thickness h of the workpiece, and partially penetrates into the thickness h' of the thin gasket. After welding, remove the gasket 3 and grind the back of the weld to ensure that the weld is flush with the substrate.

[0019] The specific embodiment of the method for eliminating the incomplete penetration of the friction stir welded joint and the weak connection at the root of the present invention includes the follo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com