Solid-liquid separation device and solid-liquid separation method for slurry bed reactor

A solid-liquid separation and reactor technology, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problem of separation accuracy, long-term operation equipment investment and operation economy. frequency, cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

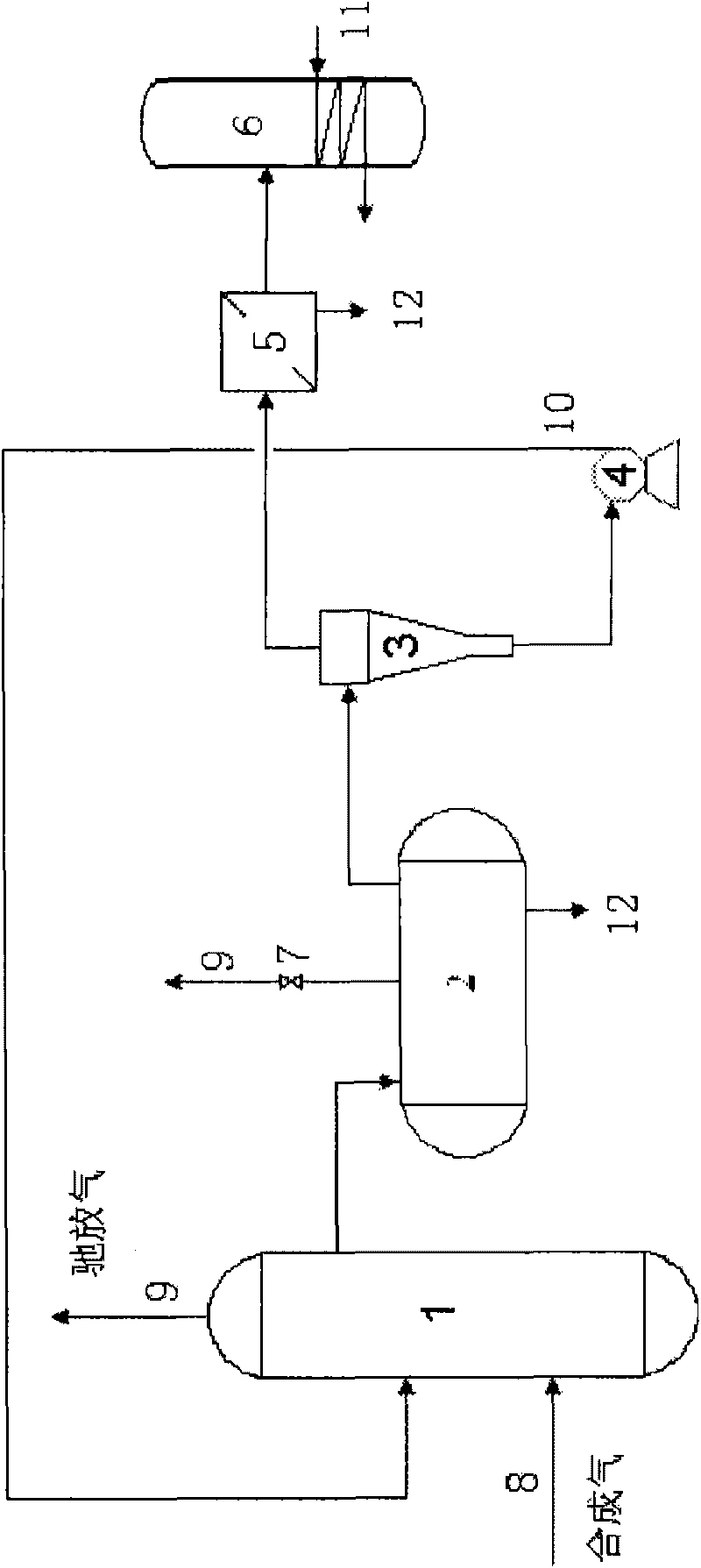

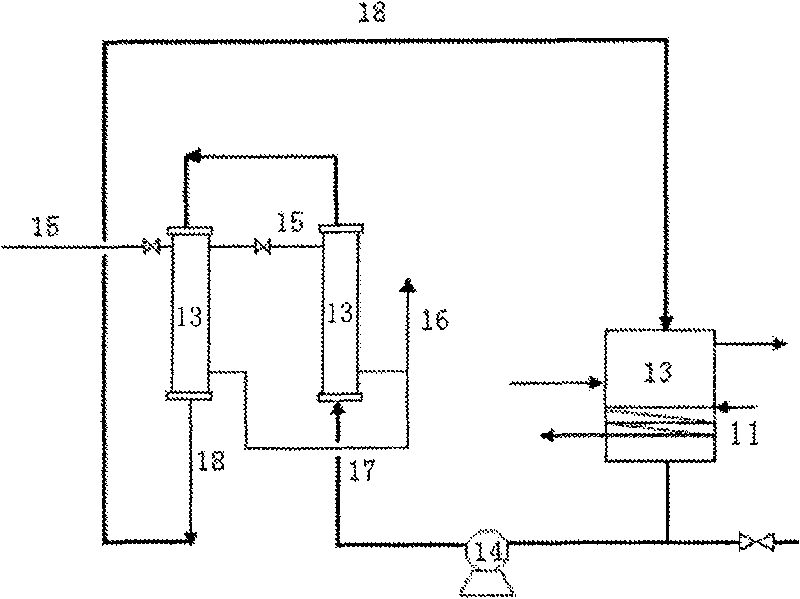

[0034] The structure of the cyclone is simple, the floor area is small, the separation efficiency is high, and it is easy to maintain. It is a very effective operating equipment for heterogeneous phase separation. Suitable for occasions with strict separation requirements. However, the inventors have found that when the cyclone is combined with the settling system and the membrane separation system for the slurry bed reactor, excellent results and ideal results have been achieved in terms of separation accuracy, equipment service life, and operating economy. balance.

[0035] For the slurry bed reactor, because the solid content in the treated material is relatively high (10%-50%), and the particle size distribution range is wide (<100 μm), the step separation method of the present invention has achieved outstanding substantive effects. In a preferred embodiment, the particles larger than 50 μm are first removed in the sedimentation system, and then the particles above 5 μm a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com