Digital electronic ballast circuit for gas discharge cold light source lamp

An electronic ballast and gas discharge technology are applied in the field of digital electronic ballast circuits for gas discharge cold light source lamps to achieve the effects of temperature rise and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

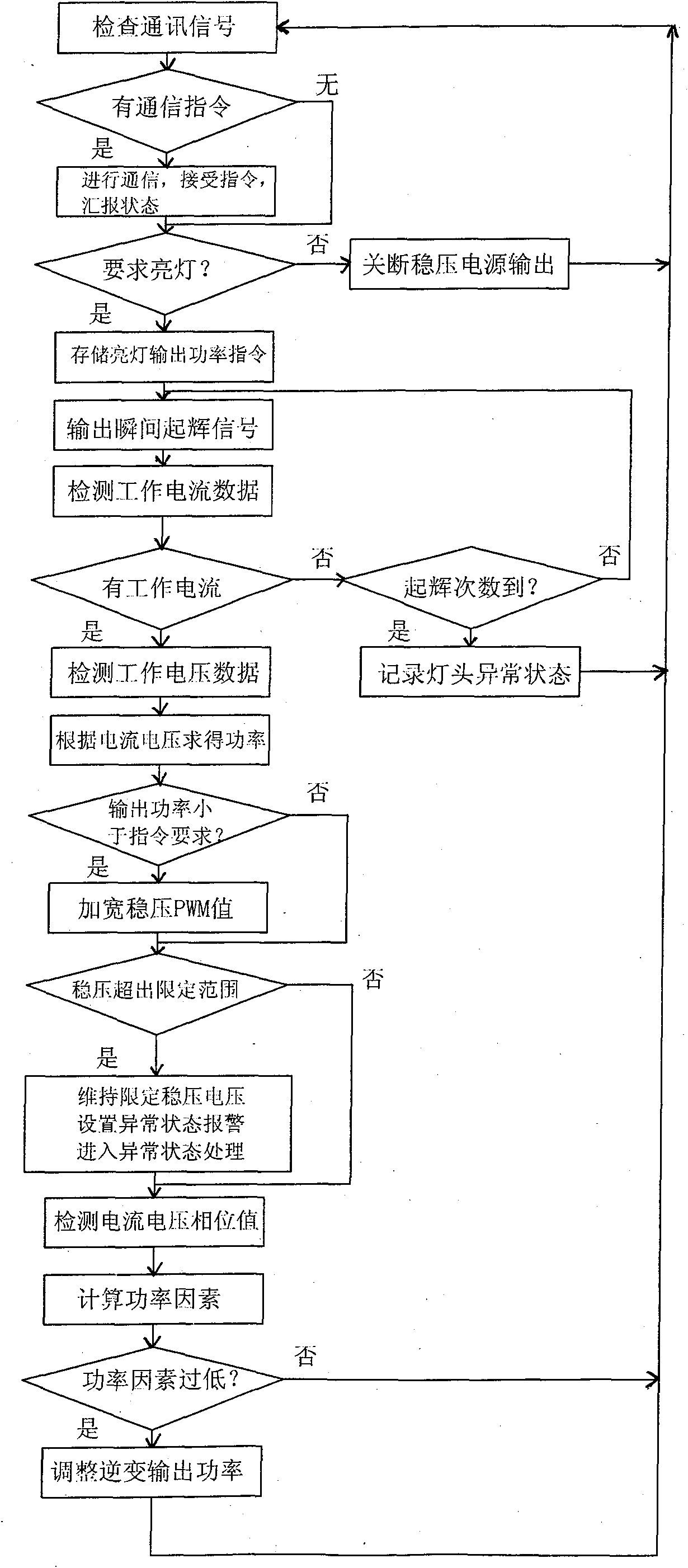

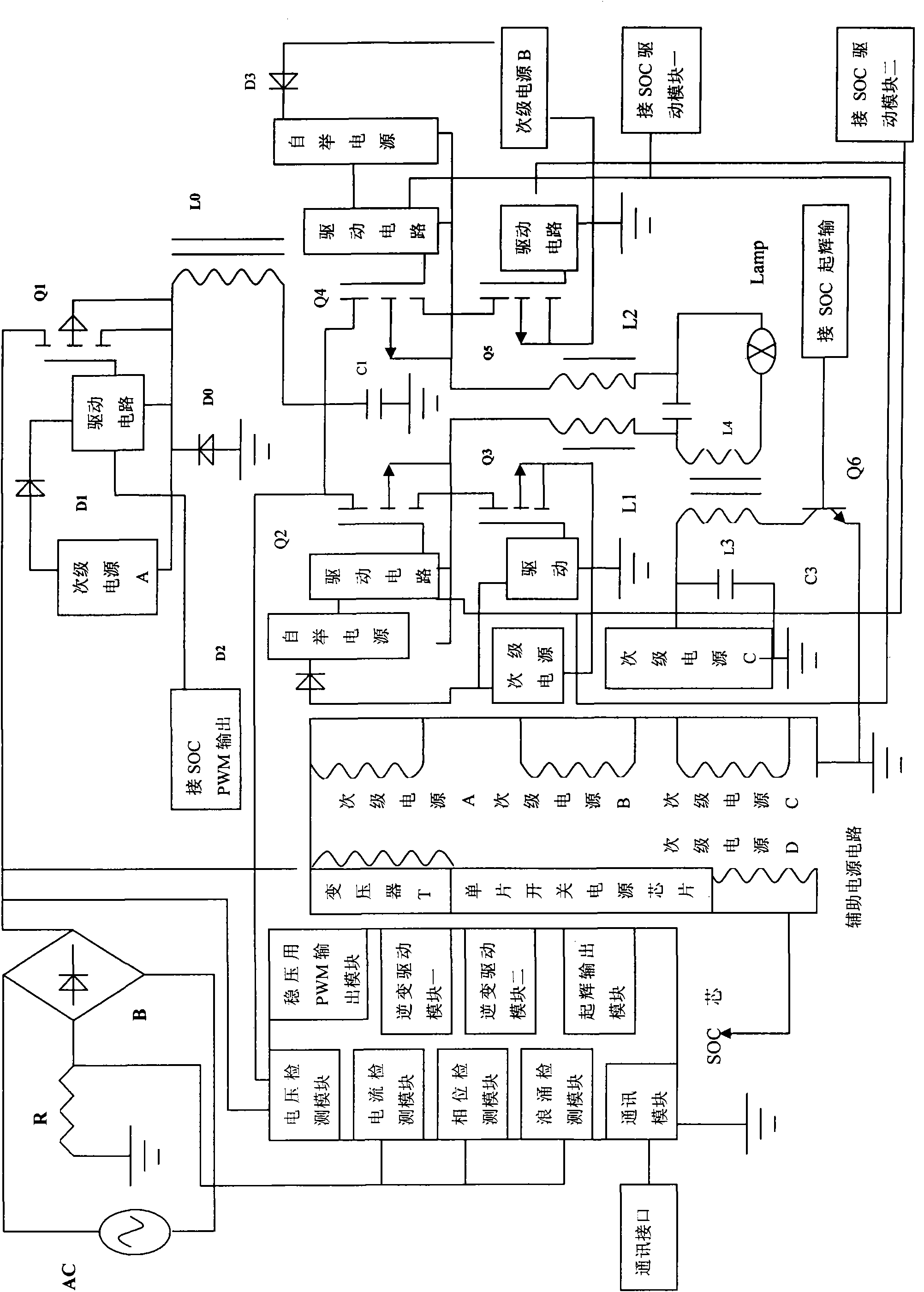

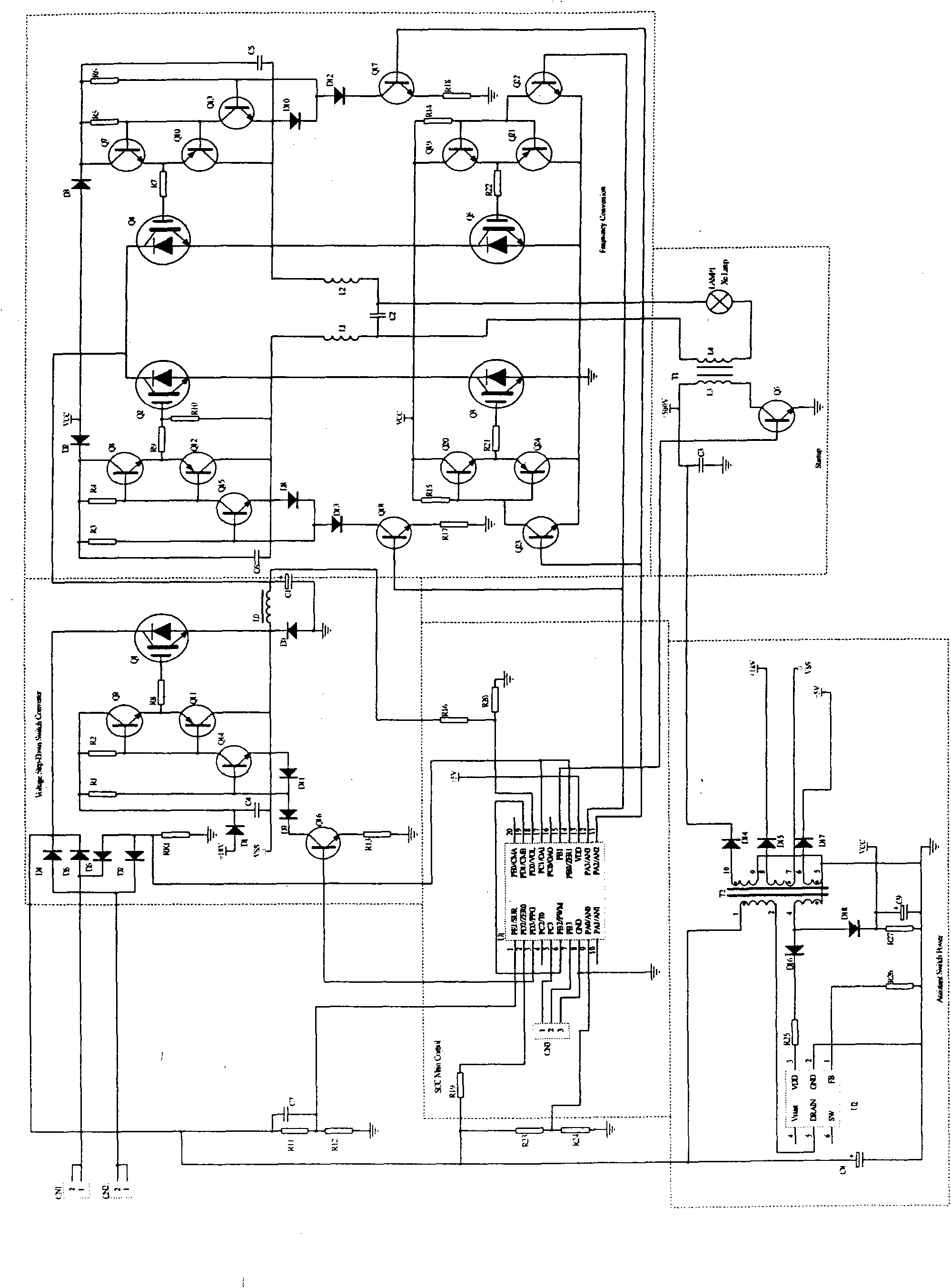

[0029] Such as Figure 1 to Figure 8 shown. A digital electronic ballast circuit for gas discharge (cold light source) lamps, including a SOC control part, a rectifier circuit part, a series voltage regulator part, an inverter part, a glow circuit part and an auxiliary power supply part. electrical connection;

[0030]The SOC control part includes a SOC chip U1, which is connected with a transformer T2, a series voltage regulator part, an inverter part, an auxiliary power supply part, a rectifier bridge circuit, and a series voltage regulator part through wires. The rectifier circuit part includes a rectifier bridge circuit composed of four diodes D4, D5, D6, and D7, which are connected with external mains power supply, SOC control part, auxiliary power supply part, and series voltage regulator part respectively. The series regulator part is composed of Q1, L0, and D0. It rectifies the AC mains of about 100-270V to obtain a DC power supply of about 150-400V to a voltage of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com