Method of Reactive Power Compensation Switching of Low-voltage Thyristor in Metallurgical Electric Furnace

A thyristor switching and thyristor technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as operating overvoltage, short service life, switching, etc., and achieve fast response and extended service life , to avoid the effect of overfilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

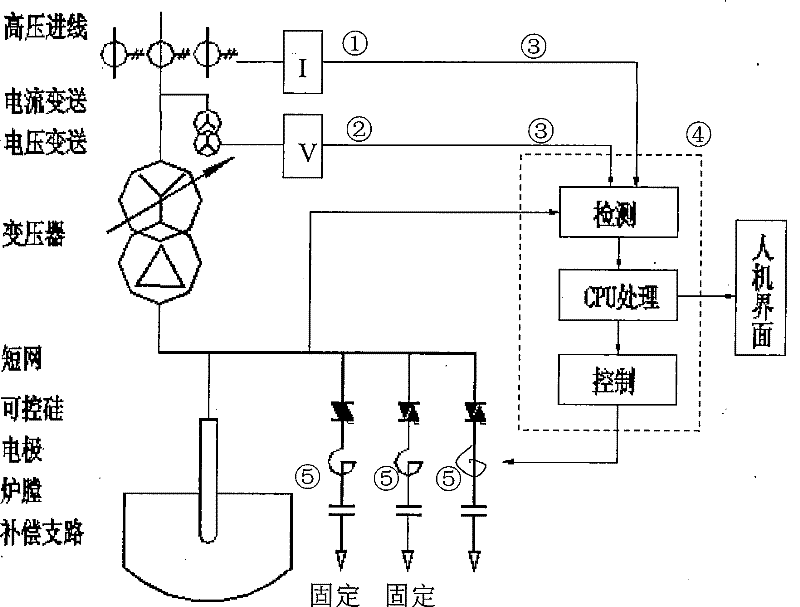

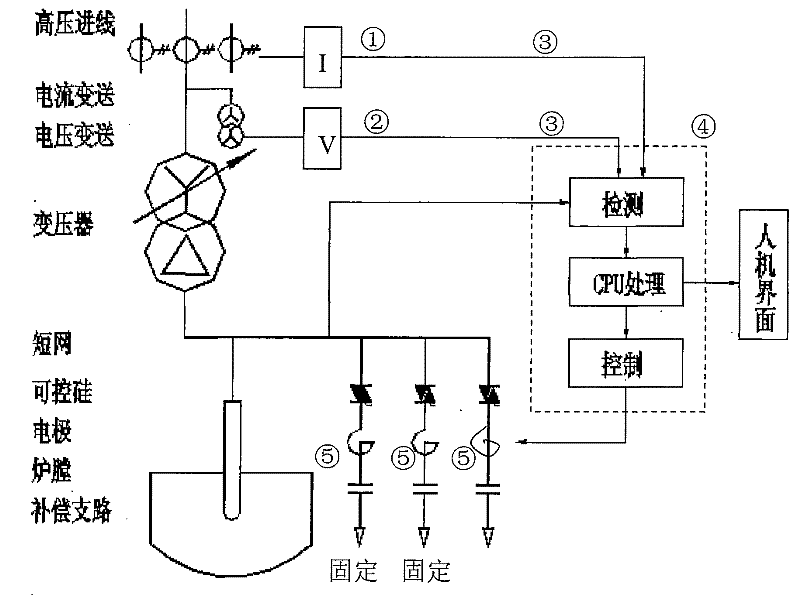

[0028] Such as Figure 1-2 As shown, the applications of the present invention are as follows:

[0029] 1. On the terminal block of the switch cabinet on the high voltage side of the metallurgical electric furnace, the three-phase current and voltage signals of A, B, and C are passed through the current transmitter ① and voltage transmitter ②, and the secondary signal is transmitted to the controller input terminal through the communication wire ③. The controller sends out a pulse trigger signal after processing by the CPU system.

[0030] 2. When the power of the metallurgical electric furnace is ≤0.9, the pulse signal drives the static fixed switching unit. When the voltage crosses zero, each group of thyristors of each phase is turned on in sequence at a time interval of 1 cycle, so that the power factor reaches 0.9.

[0031] 3. When the power of the metallurgical electric furnace reaches 0.9, the controller will continue to sample and analyze, and send a pulse signal to the swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com