Method for preparing BiFeO3 based multiferroic composite material

A composite material and synthesis process technology, applied in the field of material science, can solve the problem of small macroscopic magnetic moment, achieve the effects of short sintering time, uniform and dense sample structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

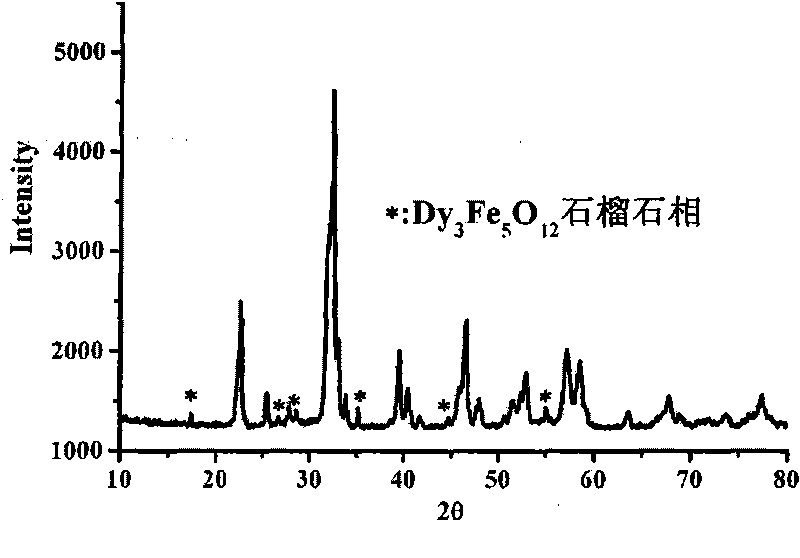

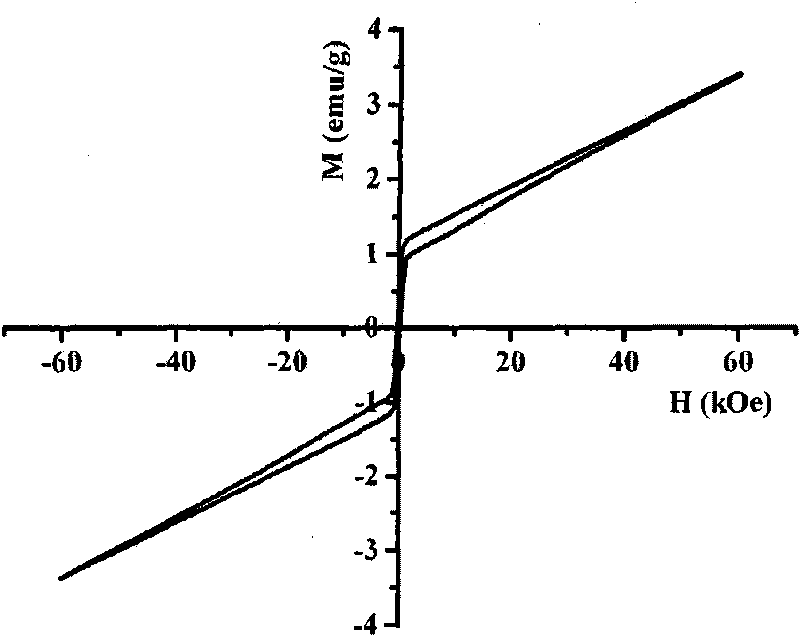

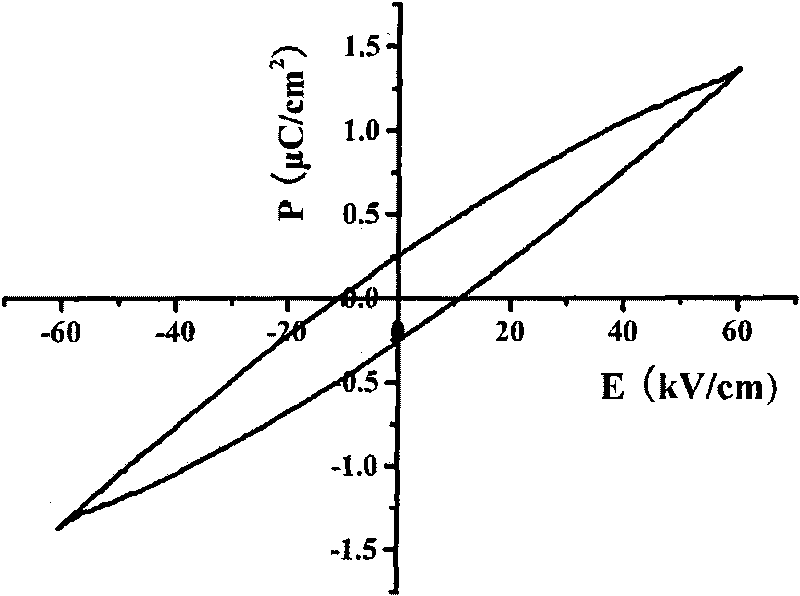

[0015] According to the theoretical chemical formula Bi 0.8 Dy 0.2 Fe 0.98 Ti 0.02 o 3.01 Weigh 0.04mol Bi respectively 2 o 3 , 0.01mol Dy 2 o 3 , 0.049molFe 2 o 3 and 0.002mol TiO 2 , and fully grind it in an agate mortar or ball mill for about 1 hour, and mix evenly; press the above mixture into tablets with a tablet machine, and then pretreat the pressed tablets in a tube furnace or a box furnace at a temperature of 600°C, the treatment time is one hour, and then cooled to room temperature with the furnace; the pretreated sheet samples are then placed in an agate mortar or ball mill to fully pulverize and grind for about 1 hour, and then pressed into tablets again. Finally, the second sintering is carried out. The sintering temperature is 880°C and the sintering time is 20min. Take out and anneal at room temperature. figure 1 is the X-ray diffraction pattern (XRD) of the composite material, indicating that the main phase of the composite material is an orthorhom...

Embodiment 2

[0017] According to the theoretical chemical formula Bi 0.8 Dy 0.2 Fe 0.99 Ti 0.01 o 3.005 Weigh 0.04mol Bi respectively 2 o 3 , 0.01mol Dy 2 o 3 , 0.0495molFe 2 o 3 and 0.001mol TiO 2 , and fully grind it in an agate mortar or ball mill for about 1 hour, and mix evenly; press the above mixture into tablets with a tablet machine, and then pretreat the pressed tablets in a tube furnace or a box furnace at a temperature of 600°C, the treatment time is one hour, and then cooled to room temperature with the furnace; the pretreated sheet samples are then placed in an agate mortar or ball mill to fully pulverize and grind for about 1 hour, and then pressed into tablets again. Finally, the second sintering is carried out. The sintering temperature is 850°C, and the sintering time is about 20 minutes. Take it out and anneal at room temperature to get the BiFeO 3 based multiferroic composites.

Embodiment 3

[0019] According to the theoretical chemical formula Bi 0.8 Dy 0.2 Fe 0.97 Ti 0.03 o 3.015 Weigh 0.04mol Bi respectively 2 o 3 , 0.01mol Dy 2 o 3 , 0.0485molFe 2 o 3 and 0.003mol TiO 2 , and fully grind it in an agate mortar or ball mill for about 1 hour and mix evenly; press the above mixture into tablets with a tablet machine, and then pretreat the pressed tablets in a tube furnace or a box furnace at a temperature of 600 °C, the treatment time is one hour, and then cooled to room temperature with the furnace; the pretreated flake samples are then placed in an agate mortar or ball mill to fully pulverize and grind for about 1 hour, and then compressed into flakes again. Finally, the second sintering is carried out. The sintering temperature is 900°C, and the sintering time is about 20 minutes. Take it out and anneal at room temperature to get the BiFeO 3 based multiferroic composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com