Process and equipment for grinding nanometer fluid

A nano-fluid and grinding technology, used in grinding/polishing equipment, metal processing equipment, grinding/polishing safety devices, etc. The effect of increasing the lubricating area, enhancing the cooling performance, and high processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

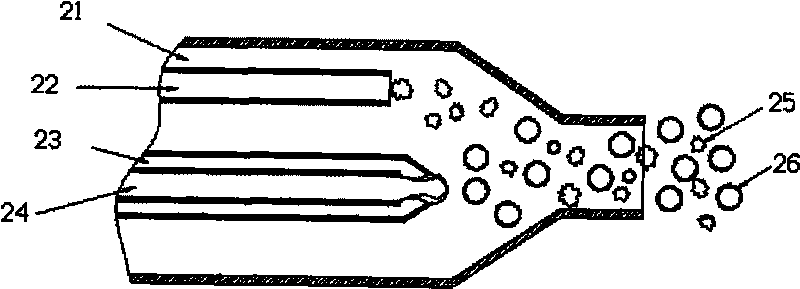

[0018] The introduction of nanomaterials into the grinding process is mainly due to the fact that nanomaterials have extremely low substance content and good thermal conductivity. Its implementation process must do two aspects of work: one is to select appropriate materials and working parameters, and the other is to develop appropriate equipment.

[0019] A large number of experiments have shown that the range of nanomaterials used is very wide, which can be metal powders, such as copper, aluminum, zinc, etc., or oxide powders, such as aluminum oxide, zinc oxide, zirconium oxide, etc. Its working parameter range is also very wide, such as the particle size of nanomaterials is between 1-100nm, the volume percentage of the delivery volume is 1-10vol%; the intake volume of high-pressure air is 10-100L / Min; the supply volume of water is 200- 800ml / h; lubricating oil 10-50ml / h, both have satisfactory results.

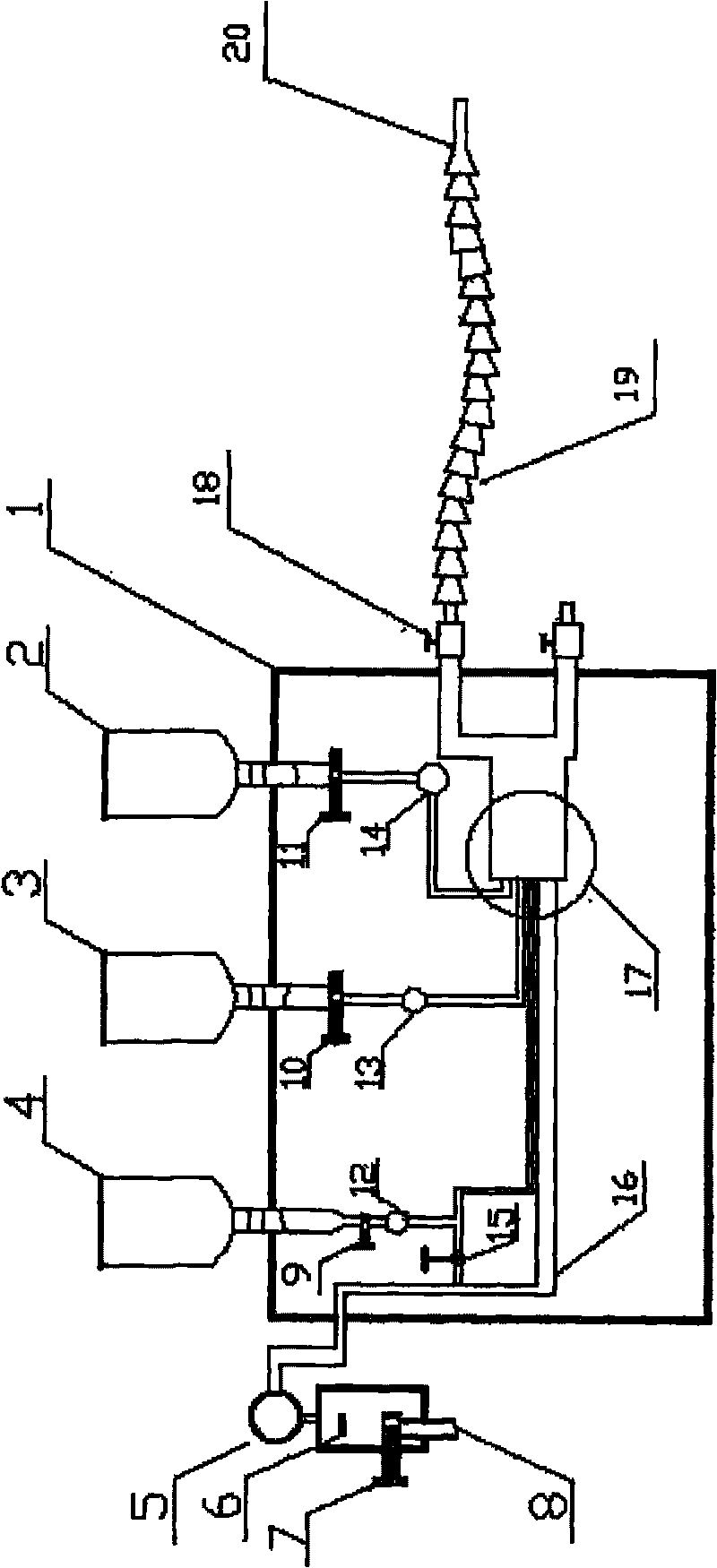

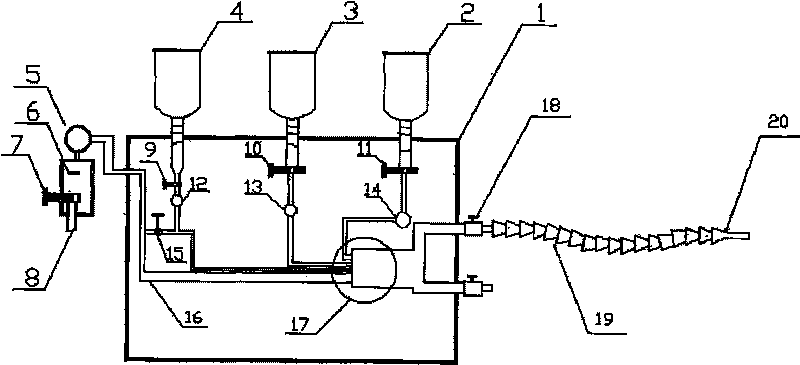

[0020] figure 1 One of the simplest equipment is introduced. It can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com