Carbon doped boron-nitrogen nanotube/semiconductor oxide composite and preparation method and application thereof

A composite material and nanotube technology, which is applied to carbon-doped boron nitride nanotubes/semiconductor oxide composite materials and their preparation and application fields, can solve the problems of low sensitivity and slow response speed, and achieves fast response speed and application method. Simple, highly gas-sensitive and responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

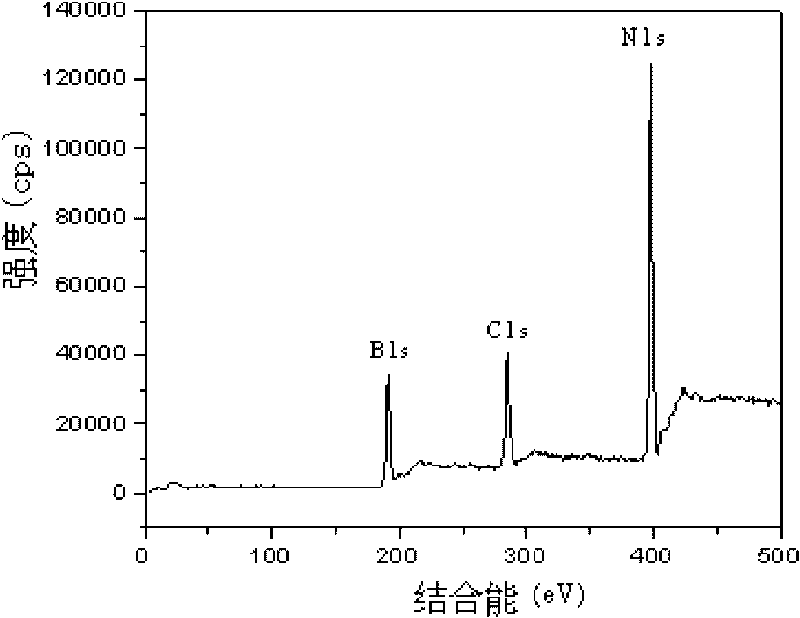

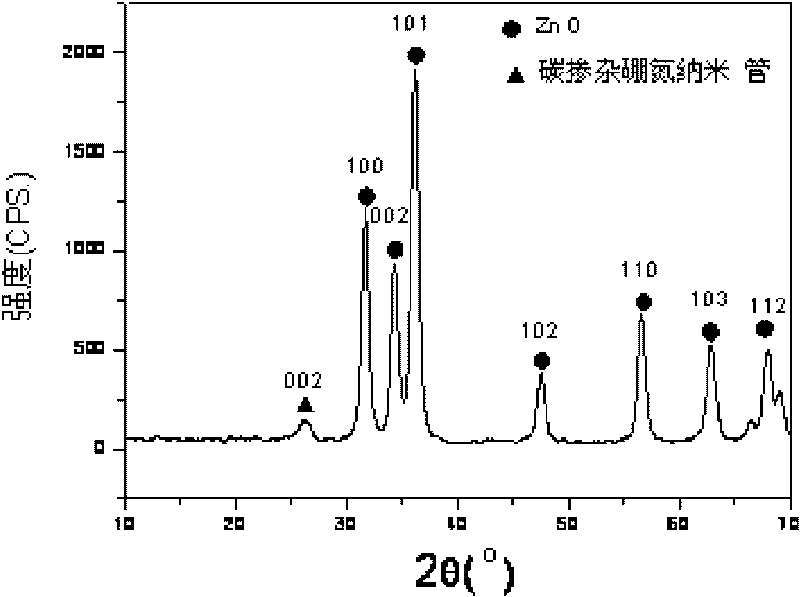

[0015] Embodiment 1: The carbon-doped boron-nitrogen nanotube / semiconductor oxide composite material in this embodiment is made of carbon-doped boron-nitrogen nanotube, transition metal salt and precipitant; wherein carbon-doped boron-nitrogen nanotube and transition The mass ratio of the metal salt is 1: 2 to 45; the molar ratio of the transition metal salt to the precipitating agent is 1: 1 to 5; 3-6.5 parts of boron-containing materials and 4-25 parts of carbon nanotubes are sintered in an ammonia atmosphere to prepare boron carbon nitrogen nanotubes, and then the boron carbon nitrogen nanotubes are purified and calcined.

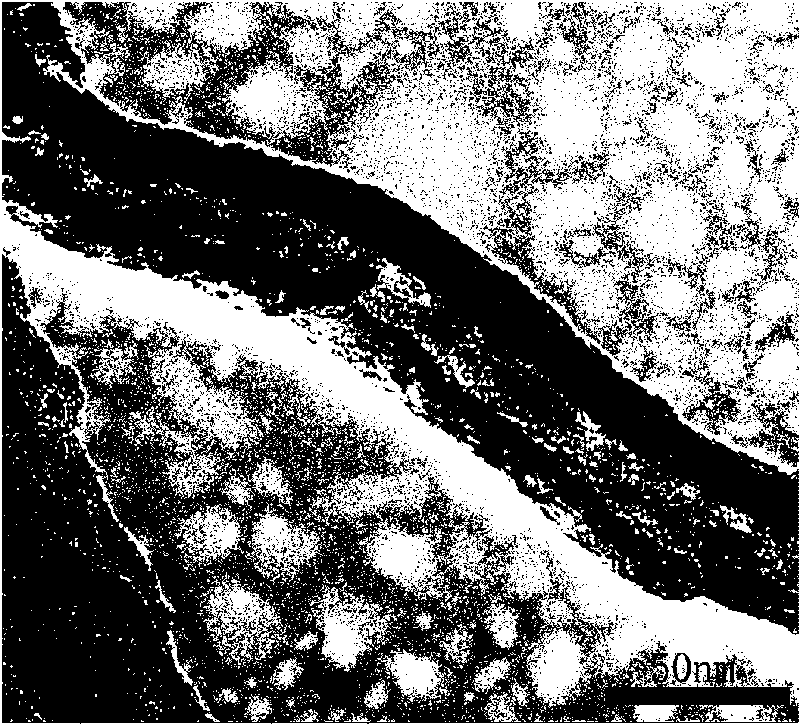

[0016] The carbon-doped boron-nitrogen nanotube / semiconductor oxide composite material in this embodiment has a uniform tubular structure, and the surface is evenly compounded with semiconductor oxides with a particle diameter of about 10-15 nm. The nanoscale semiconductor oxide particles have a higher gas density. Sensitivity and responsiveness. The se...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the catalyst is α-Fe 2 o 3 or γ-Fe 2 o 3 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the boron-containing material is amorphous boron powder, crystalline boron powder or boric acid. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com